An internal member and a fluidized bed reactor comprising the internal member

A technology of fluidized bed reactors and internal components, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of back-mixing of solid particles, long residence time of gas-solid two-phase, low utilization rate of catalysts, etc., to achieve Optimize the flow field, inhibit gas-solid back-mixing, and enhance the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings but not all of them.

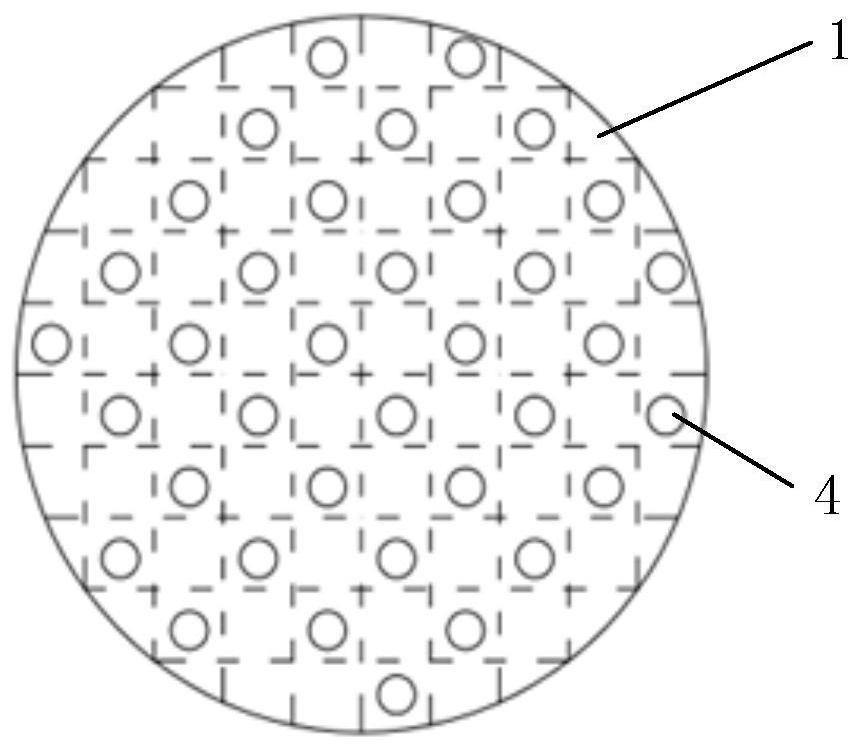

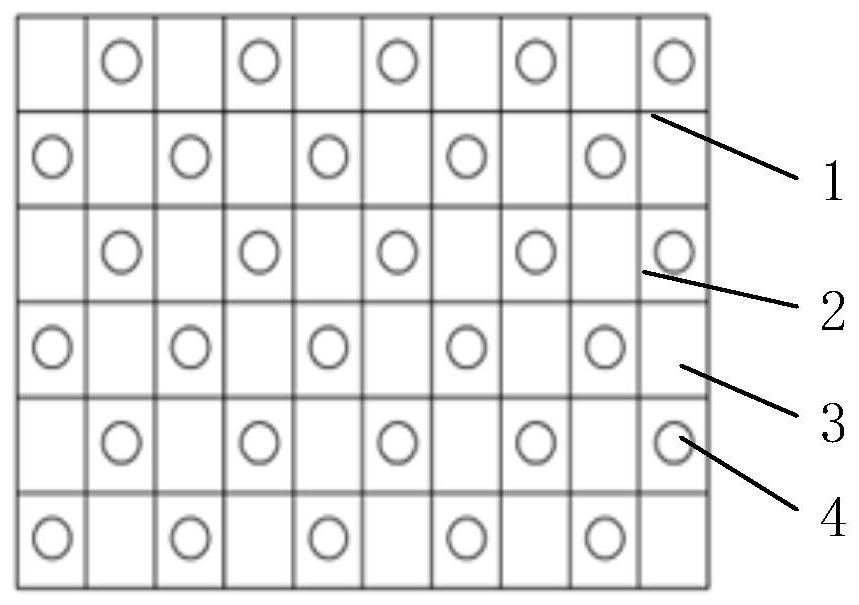

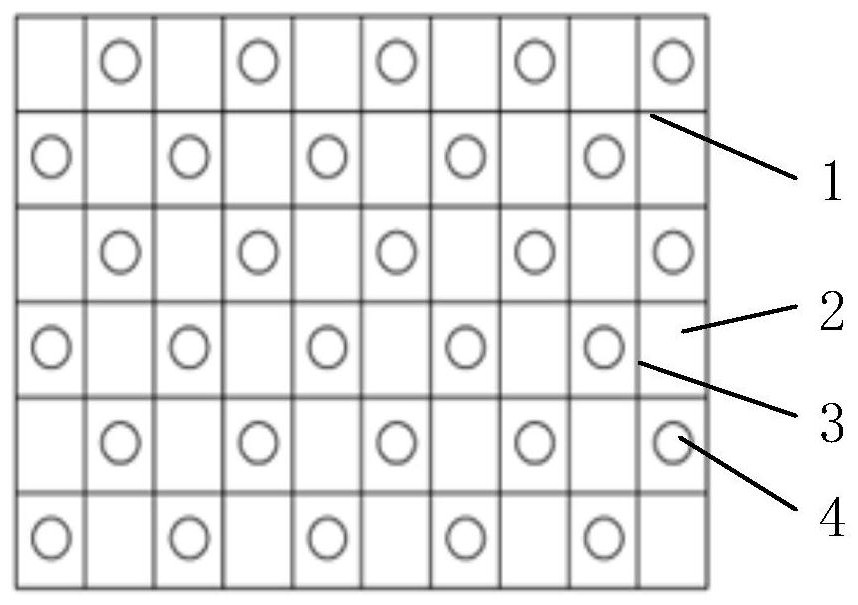

[0027] Such as Figure 1-3 As shown, the present invention provides an internal member, comprising: a plurality of circular baffles arranged in parallel and spaced apart; at least one first baffle and at least one second baffle, the first baffle and The second baffles are all arranged between the circular baffles at both ends, the first baffles and the second baffles are intersected, and both the first baffles and the second baffles are connected to the circular baffles in the middle Cross setting; air di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com