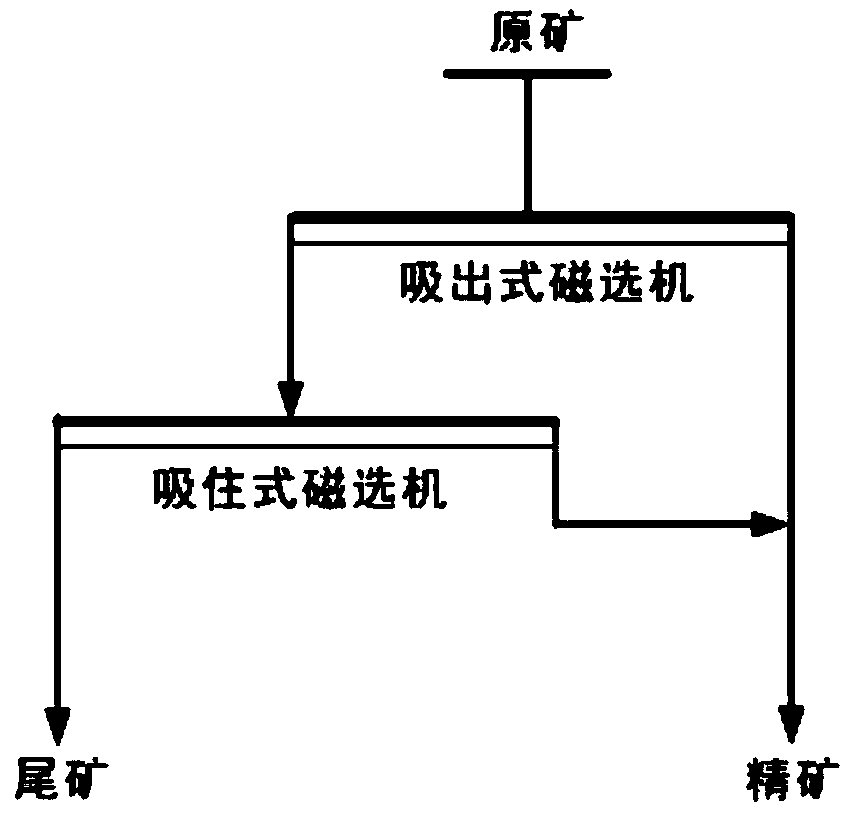

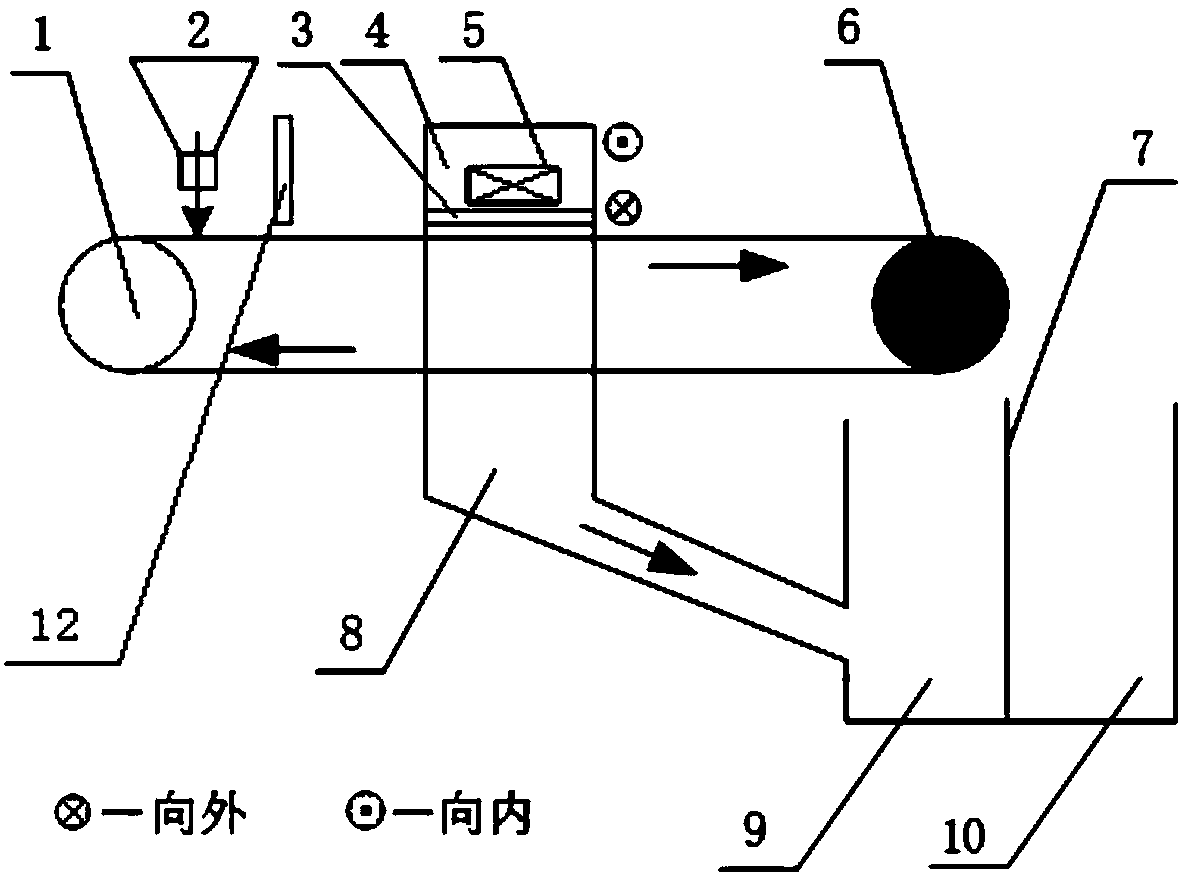

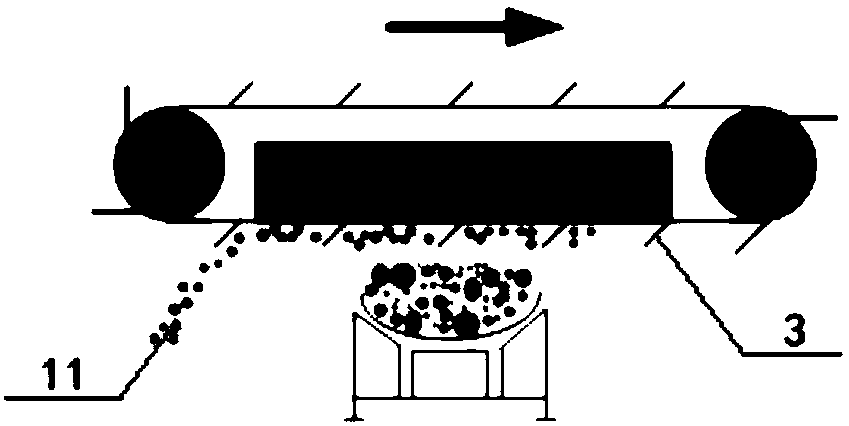

Crawler belt discharged ore suction-out and suction dry type magnetic separator and sorting method thereof

A dry magnetic separation and magnetic separator technology, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve problems such as blockage, improve separation efficiency, ensure smooth production, and reduce grinding energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The magnetite ore is crushed in three stages and one closed circuit, the product particle size is less than 12mm, accounting for 90%, and the grade is 24.50%. Use crawler discharge ore suction suction dry magnetic separator to carry out dry pre-selection, the process steps are as follows:

[0043] The working parameters for setting the crawler discharge ore suction and suction dry magnetic separator are: start the suction magnetic separator, set the magnetic field strength of the suction magnetic separator to 550mT, and the distance between the crawler of the suction magnetic separator and the ore feeding belt is 50mm. Install a leveler in front of the ore belt to scrape the mineral material, start the suction type magnetic separator, set the magnetic field strength of the suction type magnetic separator to 550mT, then start the ore feeding device to feed the ore, and feed the material into the crawler to discharge the ore Suction and hold the dry magnetic separator. Af...

Embodiment 2

[0048] The products of magnetite crushed in three stages and one closed circuit are crushed in open circuit by high-pressure roller mill. The product particle size is less than 5mm, accounting for 90%, and the grade is 23.40%. Use crawler discharge ore suction suction dry magnetic separator to carry out dry pre-selection, the process steps are as follows:

[0049] The working parameters for setting the crawler ore discharge and suction of the dry magnetic separator are: start the suction magnetic separator, set the magnetic field strength of the suction magnetic separator to 450mT, and the distance between the crawler of the suction magnetic separator and the ore feeding belt is 50mm. Install a leveler in front of the ore belt to scrape the mineral material, start the suction type magnetic separator, set the magnetic field strength of the suction type magnetic separator to 650mT, then start the ore feeding device to feed the ore, and feed the material into the crawler to discharg...

Embodiment 3

[0054] The magnetite ore is crushed in two stages and one closed circuit, and the product particle size is less than 15mm, accounting for 90%, and the grade is 25.60%. Use crawler discharge ore suction suction dry magnetic separator to carry out dry pre-selection, the process steps are as follows:

[0055] The working parameters for setting the crawler ore discharge and suction of the dry magnetic separator are: start the suction magnetic separator, set the magnetic field strength of the suction magnetic separator to 650mT, and the distance between the crawler of the suction magnetic separator and the ore feeding belt is 100mm. Install a leveler in front of the ore belt to scrape the mineral material, start the suction type magnetic separator, set the magnetic field strength of the suction type magnetic separator to 450mT, then start the ore feeding device to feed the ore, and feed the material into the crawler to discharge the ore Suction and hold the dry magnetic separator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com