Novel coiling block for coiling machine

A machine coil, a new type of technology, applied in the field of new coiler coils, can solve the problems of easy damage, difficult processing, complex jaw structure, etc., and achieve reduced springback, strong clamping force, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

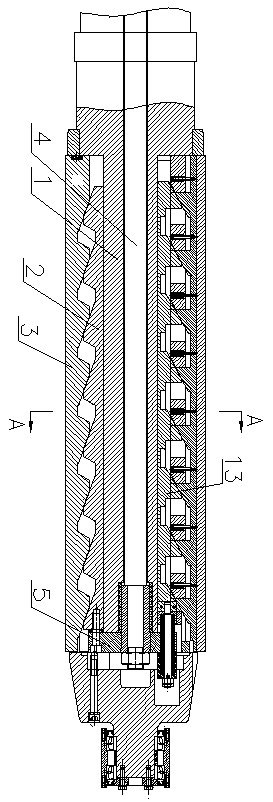

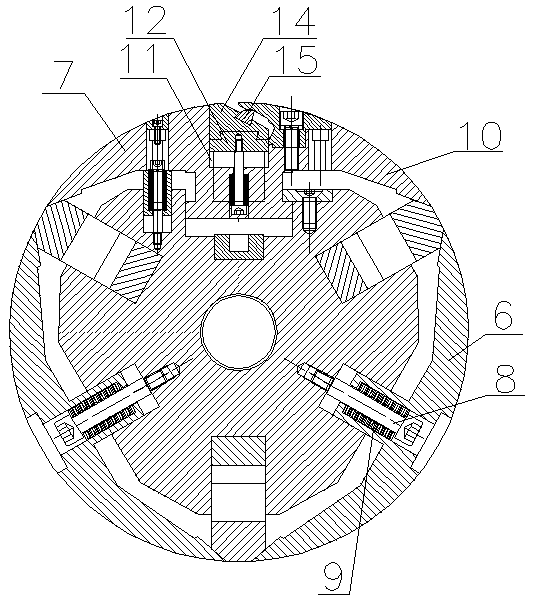

[0016] A new coiler reel, comprising a reel shaft 1, three grooves are evenly arranged in the radial direction of the reel shaft 1, a wedge-shaped block-2 is arranged in the groove, and a wedge-shaped block-2 is arranged above the wedge-shaped block-2. There is a wedge block 2 3 that cooperates with the wedge block 1 2, a through hole is provided at the center of the reel shaft 1, and a pull rod 4 is arranged in the through hole, and a connecting plate 5 is fixedly connected to one end of the pull rod 4, and the connecting plate 5 and the wedge-shaped Block one 2 is fixedly connected, is provided with fan-shaped plate 6 between adjacent wedge-shaped block two 3, wherein a fan-shaped plate 6 is the jaw fan-shaped plate 7, and the upper end face of the jaw fan-shaped plate 7 is provided with jaws, and the jaw fan-shaped plate 7 The two sides and the fan-shaped plate 6 are movably connected with the reel shaft 1 through bolts 8, a compression spring 9 is arranged between the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com