Multi-station coining device applied to upper plate of drive axle spring plate seat

A technology of spring plate seat and embossing equipment, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., and can solve the problem of low quality of embossing on the upper plate of the drive axle spring plate seat and the stability of the upper plate of the drive axle spring plate seat Poor quality, small scope of application, etc., to achieve the effect of enhancing imprinting quality, improving imprinting efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

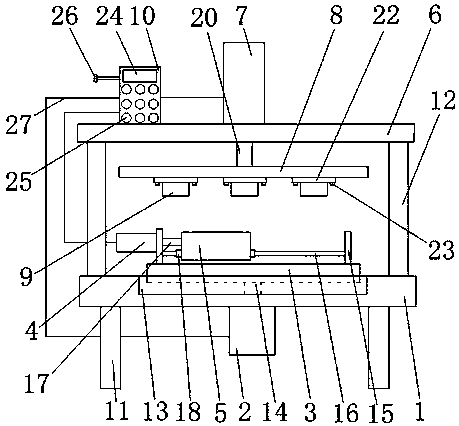

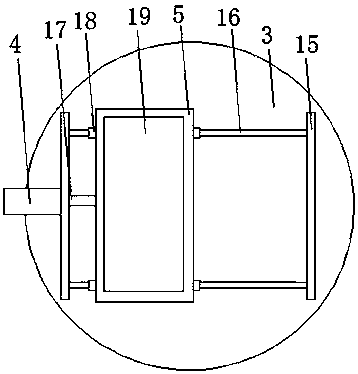

[0018] As attached Figure 1-3 As shown, a multi-station imprinting device used for the upper plate of the drive axle spring plate seat, including the console 1, the motor 2, the bearing plate 3, the cylinder one 4, the bearing block 5, the top plate 6, the cylinder two 7, and the adjustment The board 8, the imprinting mold 9 and the controller 10 are characterized in that: the operating table 1 is set on the support 11, the operating table 1 is provided with a column 12, and the operating table is located between the column 12 and the column 12 A limit slot 13 is provided on 1, the motor 2 is set on the console 1, a transmission shaft 14 is provided on the motor 2, and the transmission shaft 14 is set in the limit slot 13, and the bearing plate 3 is provided On the transmission shaft 14, a fixing plate 15 is arranged on the bearing plate 3, and a sliding rod 16 is arranged between the fixing plate 15 and the fixing plate 15. The cylinder 4 is arranged on the fixing plate 15, a...

Embodiment 2

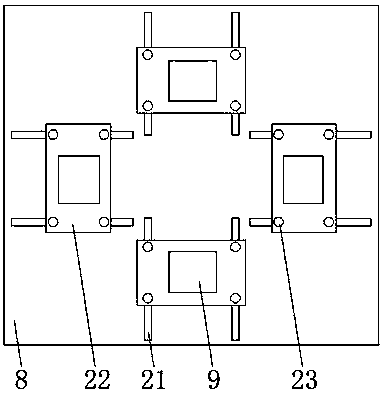

[0024] As attached Figure 4 As shown, a multi-station imprinting device used for the upper plate of the drive axle spring plate seat, including the console 1, the motor 2, the bearing plate 3, the cylinder one 4, the bearing block 5, the top plate 6, the cylinder two 7, and the adjustment The board 8, the imprinting mold 9 and the controller 10 are characterized in that: the operating table 1 is set on the support 11, the operating table 1 is provided with a column 12, and the operating table is located between the column 12 and the column 12 A limit slot 13 is provided on 1, the motor 2 is set on the console 1, a transmission shaft 14 is provided on the motor 2, and the transmission shaft 14 is set in the limit slot 13, and the bearing plate 3 is provided On the transmission shaft 14, a fixing plate 15 is arranged on the bearing plate 3, and a sliding rod 16 is arranged between the fixing plate 15 and the fixing plate 15. The cylinder 4 is arranged on the fixing plate 15, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap