Automatic installation, positioning and adjustment device for spirit bubble in spirit level

A technology for automatic installation and adjustment of devices, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and product quality consistency, high labor intensity, etc., to improve quality consistency, reduce labor intensity, The effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

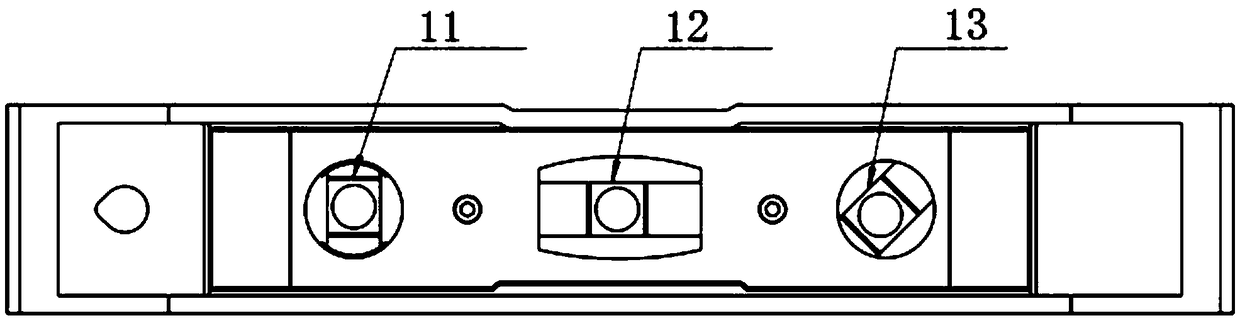

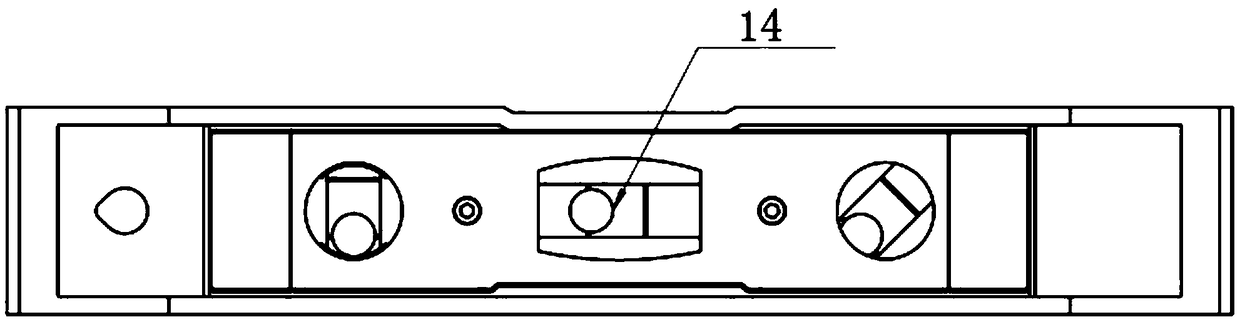

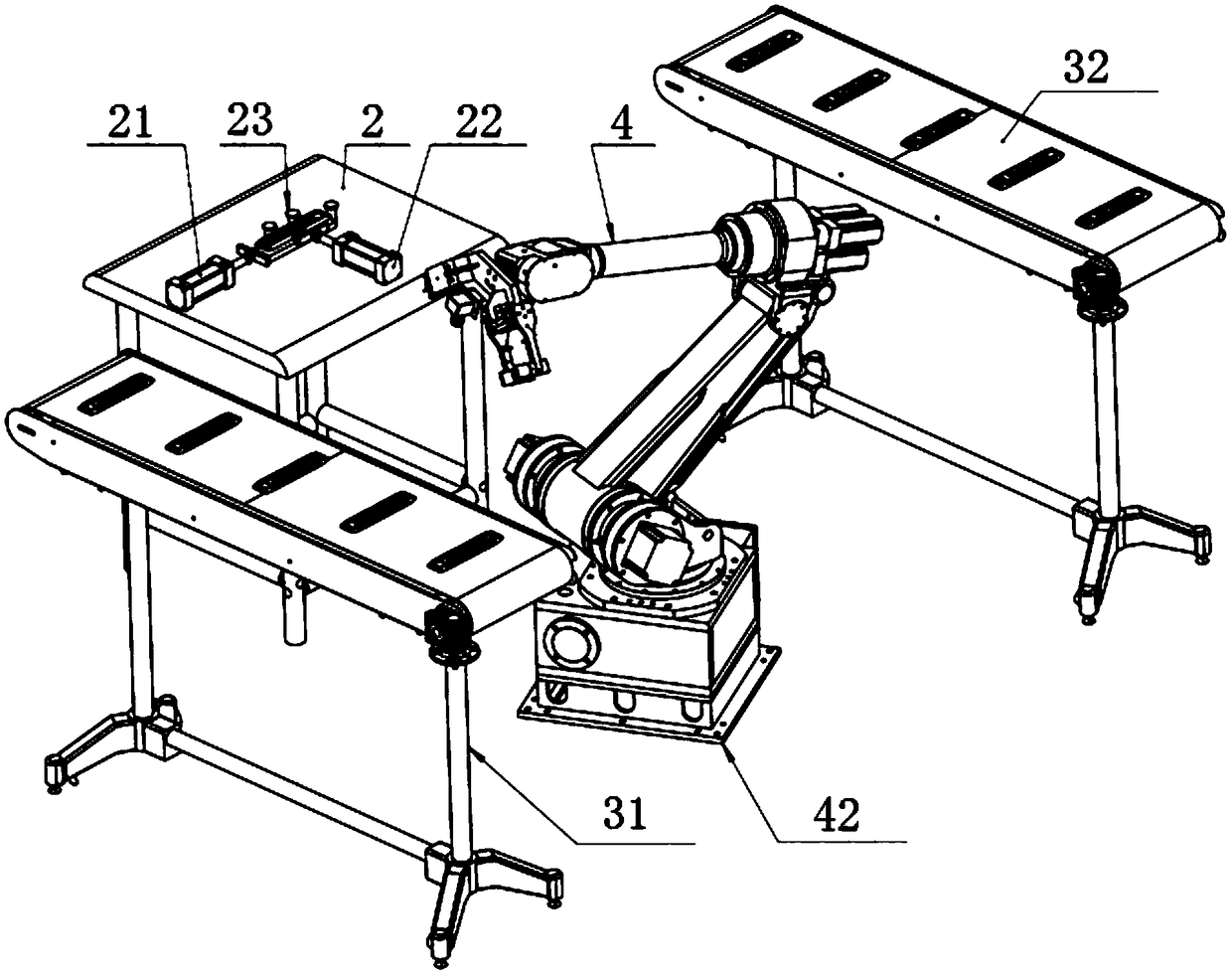

[0033] figure 1 is the position of the horizontal bubble in the spirit level under the standard horizontal state. It can be seen from the figure that the bubble position of the horizontal bubble 1 (including the horizontal bubble 11 in the Y direction, the horizontal bubble 12 in the X direction, and the horizontal bubble 13 in the 45° direction) should be at the horizontal the middle of the bubble. figure 2 is the bubble position of the horizontal bubble in the non-horizontal state, which deviates from the position in the middle theoretical horizontal state (offset state horizontal bubble 14). The horizontal bubble 1 realizes its positioning through the mounting screws at both ends. When the actual installation and inspection process finds that the bubble position is not in the middle position, the horizontal bubble position can be adjusted by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com