Automatic arrangement and implantation device for hardware pins of power supply shell

A technology for automatic arrangement and implantation of devices, which is applied in the field of automatic arrangement of implantation devices for hardware PIN needles of power shells, can solve the problems of many subjective factors, high labor costs, and difficulty in guaranteeing product quality and accuracy, so as to ensure the feeding and stamping of materials. position, avoid implantation in place, improve efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

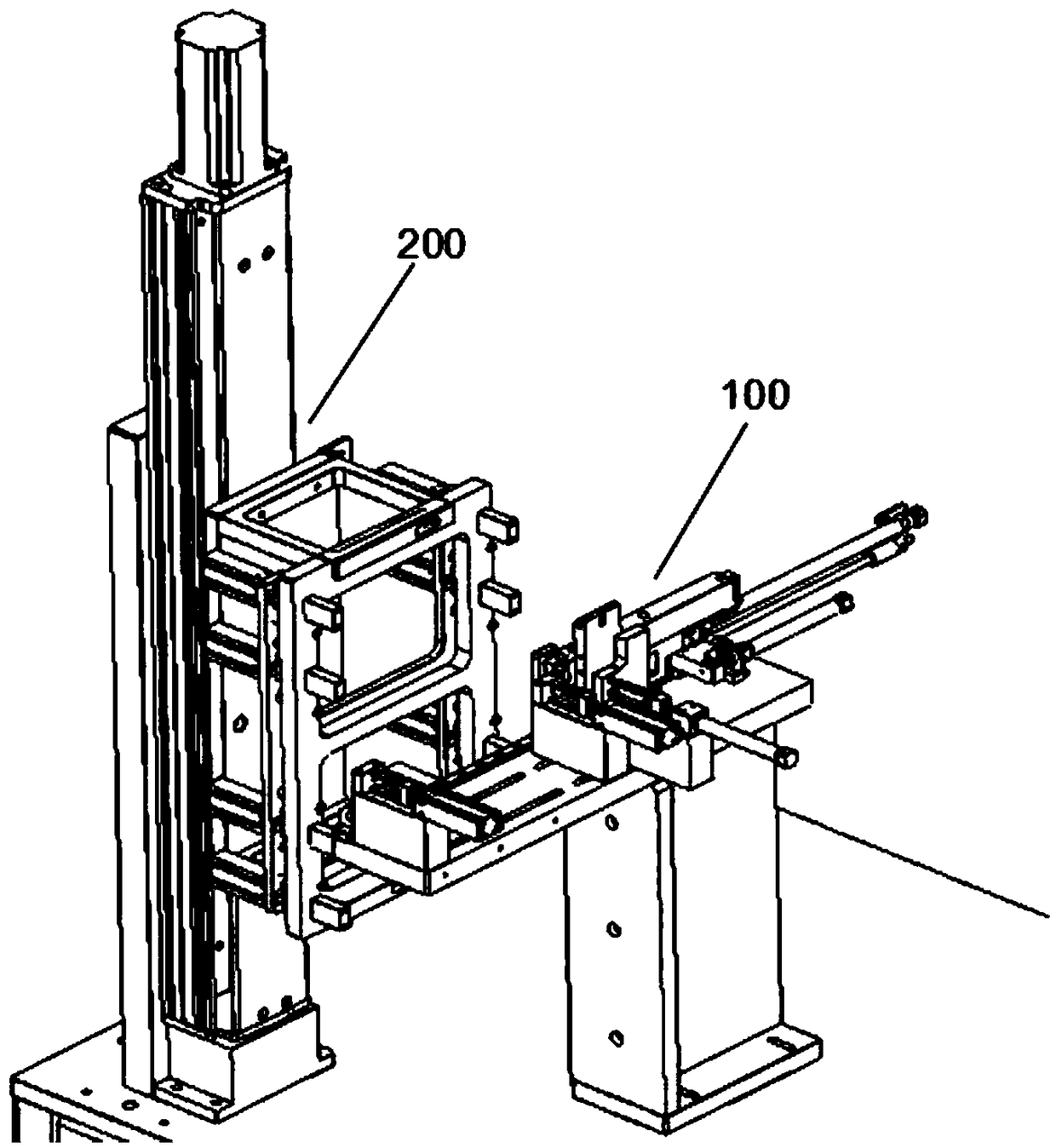

[0029] Embodiment: an implantation device for automatic arraying of hardware PIN pins of a power supply shell.

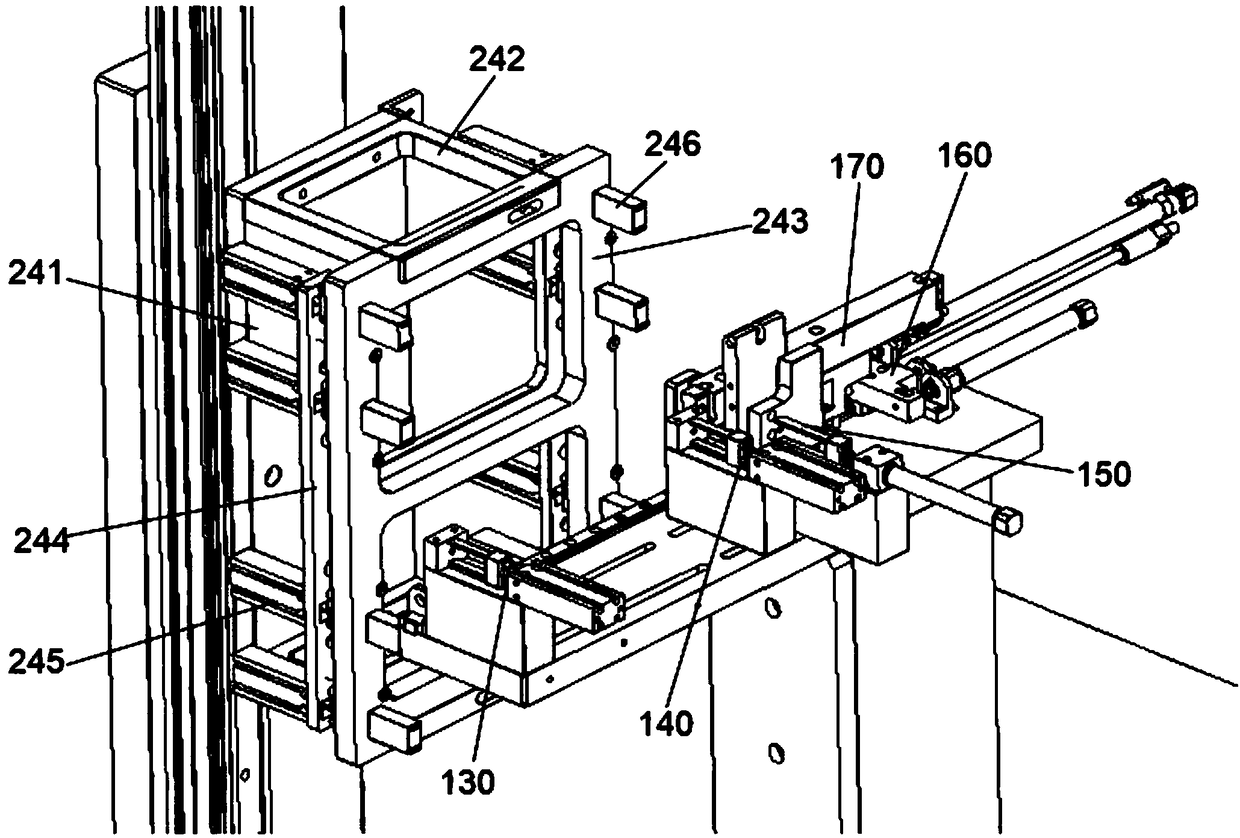

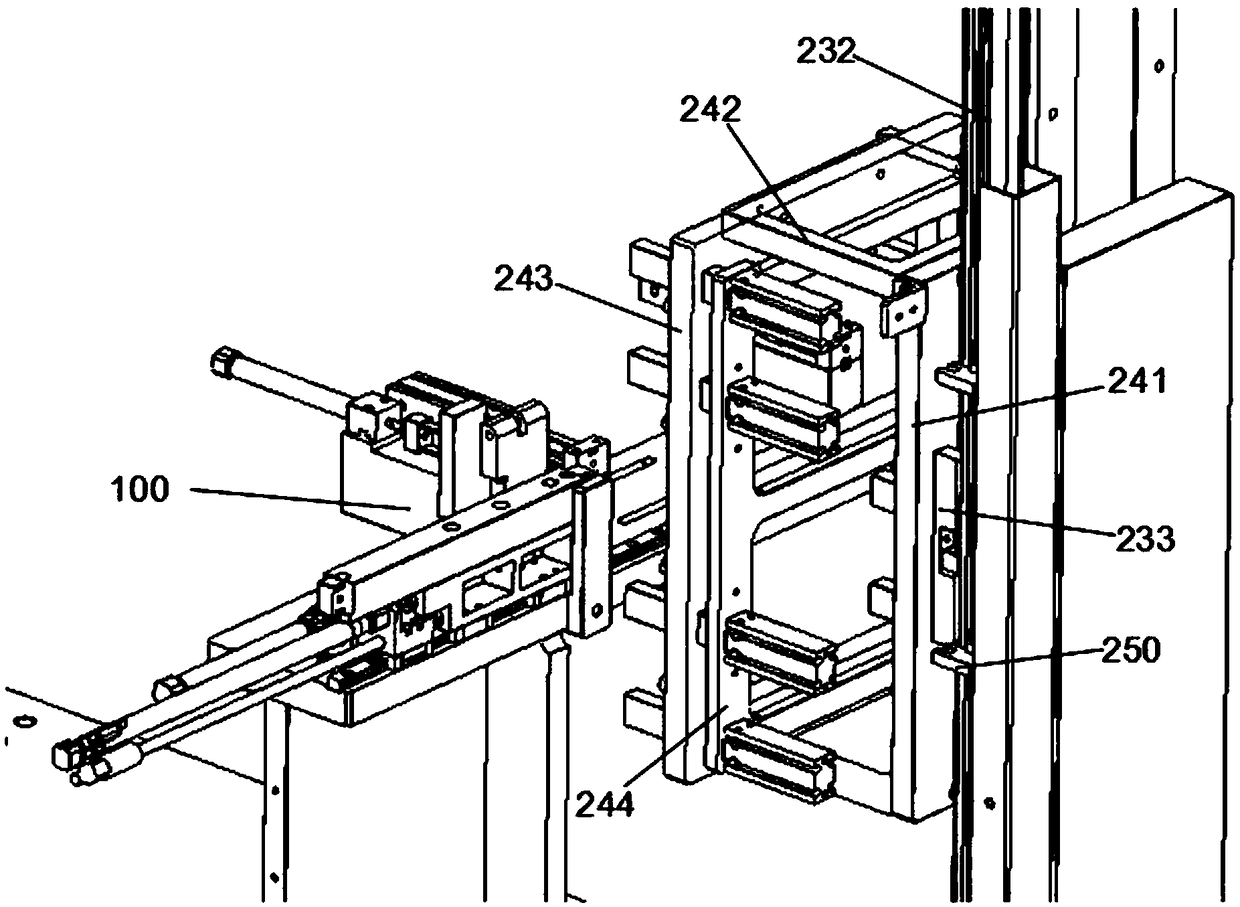

[0030] refer to Figure 1 to Figure 10 As shown, a power shell hardware PIN pin automatic arrangement implantation device, including:

[0031] Feeding mechanism 100; said feeding mechanism 100 includes a support frame 110; a mounting plate 120 installed on the top of the support frame 110, the front side of the top of the mounting plate 120 is equipped with a linear guide rail 161 arranged laterally along the mounting plate 120, the The linear guide rail 161 extends from the left side to the right side of the mounting plate 120, and limit blocks are arranged on the left and right end sides of the linear guide rail 161 to limit the maximum moving distance of the left and right end sides of the linear guide rail 161;

[0032] The sliding feeding mold 170 installed on the linear guide rail 161, the sliding feeding mold 170 is used for the transition to the movement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com