A splice truck front bumper

A front bumper, splicing technology, applied in the direction of bumpers, vehicle parts, vehicle safety arrangements, etc., can solve the problems of easily damaged car front, poor anti-collision effect of bumpers, difficult to disassemble and replace, etc., to achieve compact structure and reduce impact. The effect of strength and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

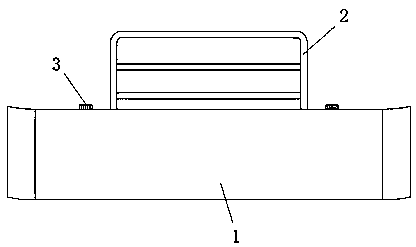

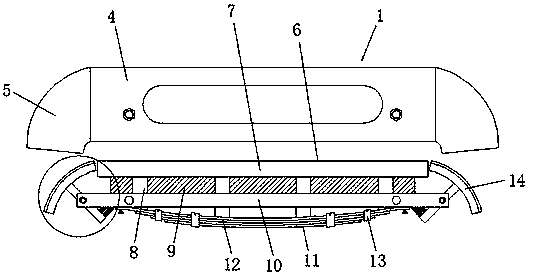

[0023] see Figure 1-4 As shown, a spliced truck front bumper includes a protective case 1, an anti-collision bar 2 and a bumper body 6, and the top of the protective case 1 is equipped with an anti-collision bar 2, and the protective case 1 is composed of a front fender 4 and a side shield The protective shell 1 is composed of a bumper body 6, and the inside of the bumper body 6 is provided with a front beam 7, a side beam 14 and a fixed plate 10, and one side of the front beam 7 is provided with several connecting rods 8, and the connecting rods 8 The outer wall of the fixed plate 10 is socketed, and an energy-absorbing layer 9 is arranged between the fixed plate 10 and the front beam 7. A buffer plate 11 is installed at one end of the connecting rod 8 through the fixed plate 10. The buffer plate 11 is composed of several steel bars 12, and several The two steel bars 12 are attached and fixed to each other by binding straps 13, the inside of the side beam 14 is provided wi...

Embodiment 2

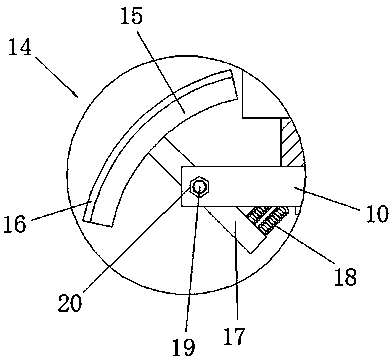

[0025] In addition, refer to Figure 1-4 , different from the above-mentioned embodiment 1, the interior of the installation groove 21 is equipped with a rotating screw rod 19, the installation rod 17 is rotationally connected with the installation groove 21 through the rotating rod screw rod 19, and the rotating screw rod 19 passes through one end of the installation groove 21 top The nut 20 and the thread 20 can be tightened so that the installation rod 17 cannot be easily rotated, so that part of the impact force received by the side beam 14 is used to rotate the installation rod 17 to offset and disappear, and part of it is offset by the spring 18, so that the side beam 14 is shock-resistant The capacity is improved. The outer wall of the support beam 15 inside the side beam 14 is in an arc-shaped structure, and the specifications of the support beam 15 match the side baffle 5. A rubber layer 16 is laid between the support beam 15 and the side baffle 5. The curved side The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com