FSE race car body

A technology for car body and rollover protection bar, applied in vehicle parts, transportation and packaging, superstructure and other directions, can solve the problems of difficult processing and manufacturing, complex design, heavy weight, etc., to reduce the difficulty of processing and manufacturing, improve competition performance and strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

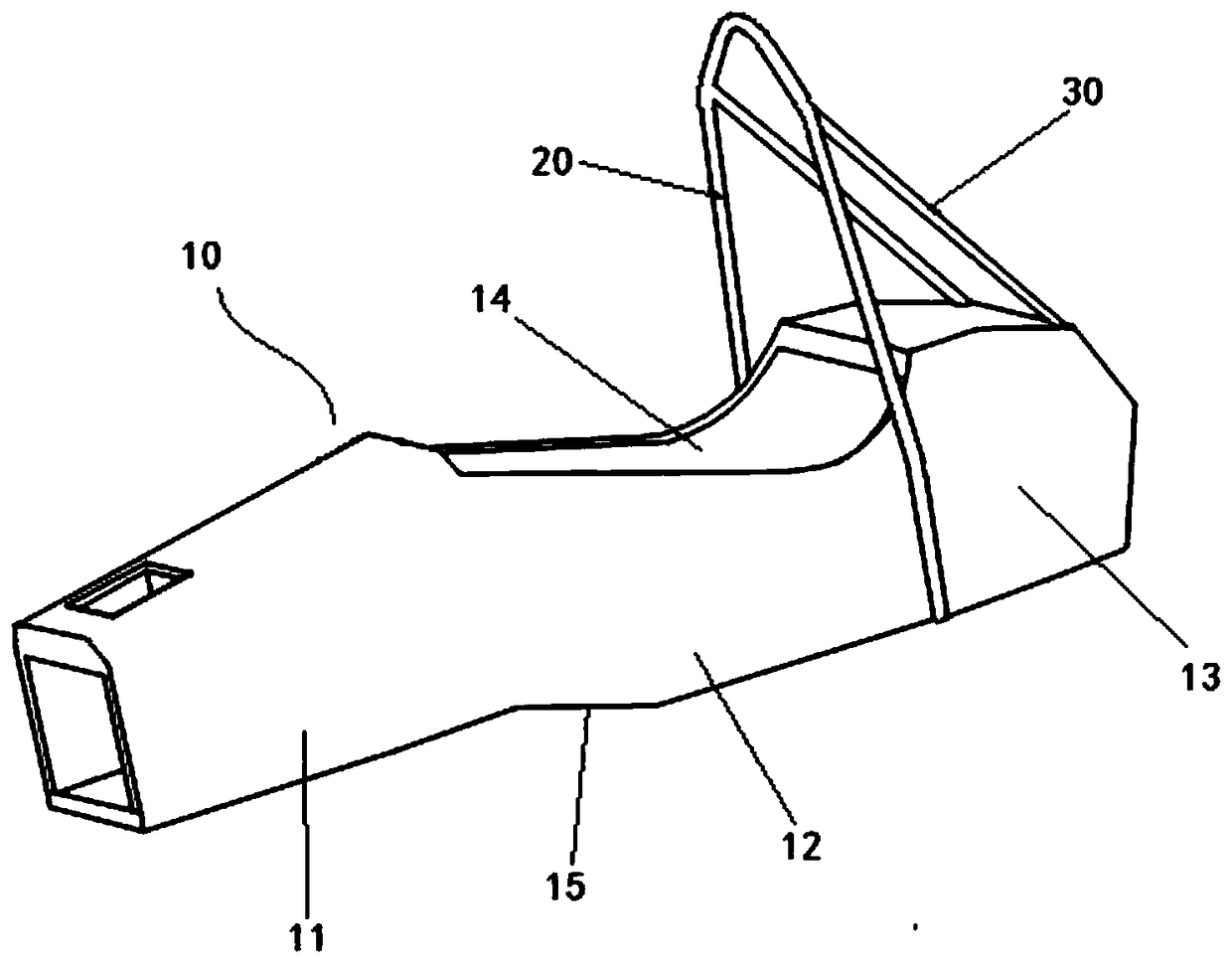

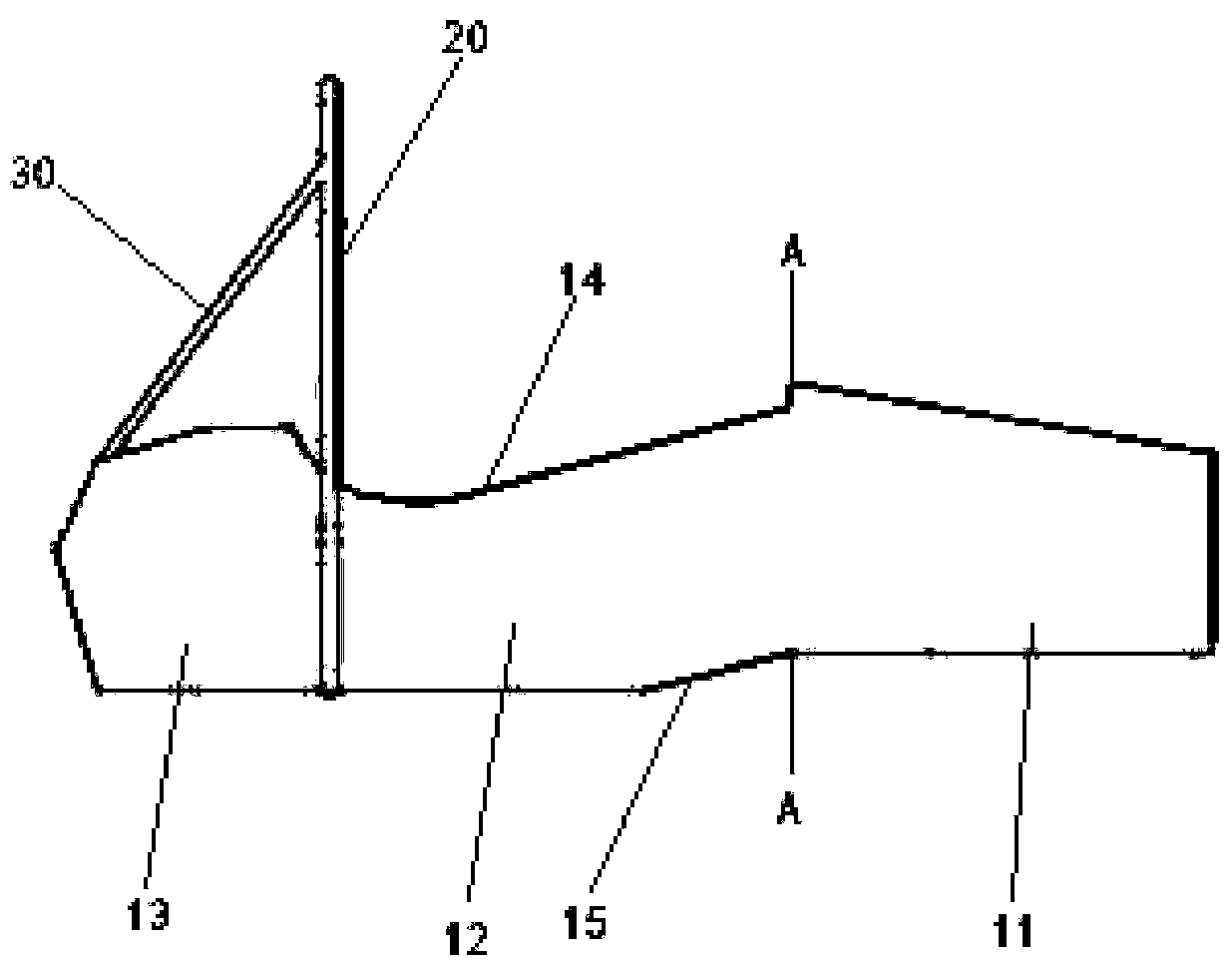

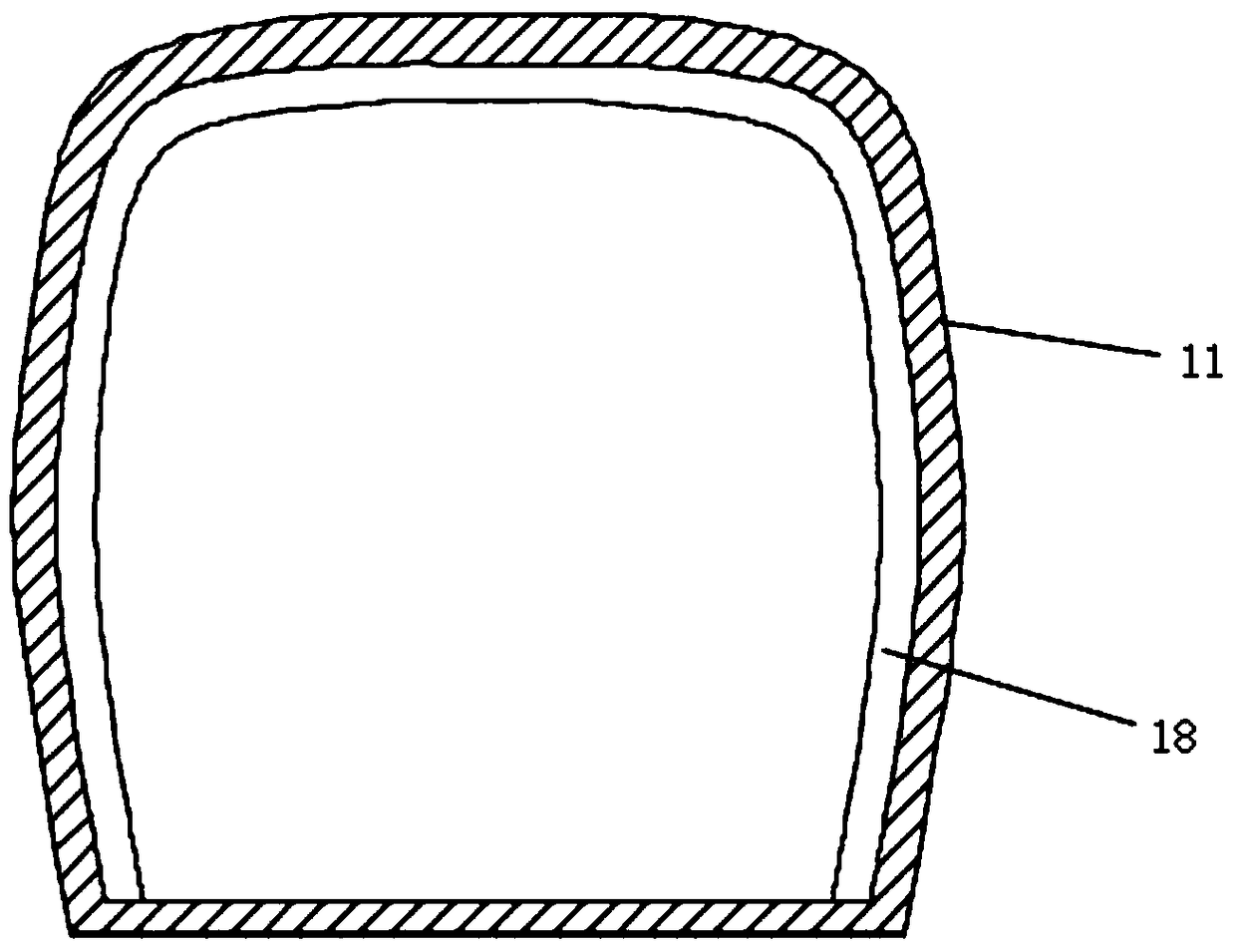

[0022] Please refer to Figure 1 to Figure 4 , An FSE racing car body, comprising a body body 10, the body body 10 is a monocoque structure, the body body 10 includes a front shell section 11, a middle shell section 12, and a rear shell section 13 that are sequentially connected back and forth. The top surface of the middle shell section 12 is an open opening 14 for the driver to enter the vehicle body. The front end of the bottom surface of the middle shell section 12 is provided with an inclined surface 15 that is high in the front and low in the rear. The bottom surface of the front shell section 11 is Plane, the rear end of the middle shell section 12 is provided with a ring-shaped rollover protection bar 20, the body body 10 is made of a sandwich material, and the sandwich material includes a carbon fiber reinforced resin composite material 16 as a panel layer and a middle sandwich layer The honeycomb aluminum core material17.

[0023] It can be seen from the above that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com