Automatic barge system for marine oil and sewage

A technology of oily sewage and lighterage, applied in water/sewage treatment, ship soil drainage, water/sludge/sewage treatment, etc., can solve problems affecting the effective discharge of sewage and restricting the performance of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

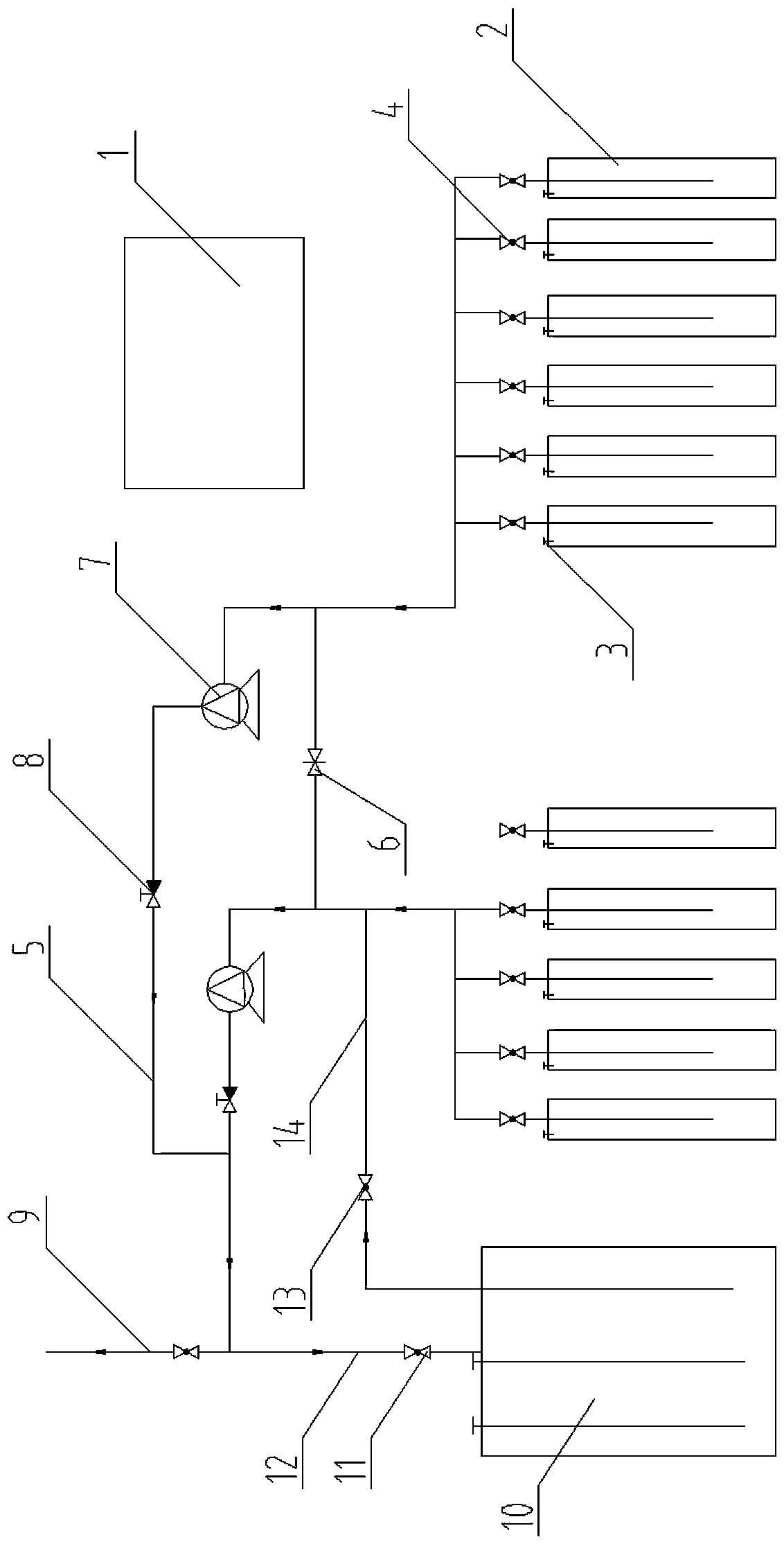

[0010] The following is a further description with reference to the drawings.

[0011] figure 1 As shown, a marine oily sewage automatic transfer system includes a master control box 1, two sets of sewage well groups composed of multiple sewage wells 2, and an oily sewage tank 10. Each sewage well 2 is equipped with a piezoelectric The sensor 3 is connected to the sewage transfer pipe 5 through the sewage electro-hydraulic proportional control valve 4, and the sewage transfer pipe 5 is connected to the transfer main pipe 9 through the transfer screw pump 7 and the transfer check valve 8, and the two sets of sewage wells are connected to the sewage transfer The pipes are connected by gate valve 6, the upper part of oil-sewage tank 10 is connected to main transfer pipe 9 via oil-sewage transfer pipe 12 with oil-sewage electro-hydraulic proportional control valve 11, main transfer pipe 9 is connected to outboard or port, and the lower part of oil-soil tank 10 is connected with The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com