Molded fabric for highly efficient papermaking machine

A paper machine, high-efficiency technology, applied in the direction of textiles and papermaking, sewing machine needle seat, sewing machine components, etc., can solve the problems of insufficient sewing strength, high labor cost, low efficiency, etc., to reduce operating steps, save operating time, Effect of increasing suture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

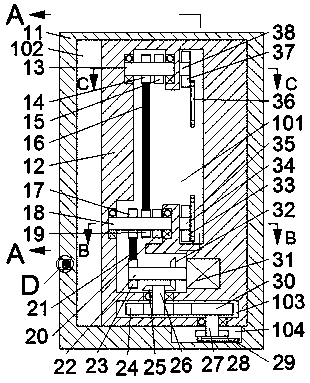

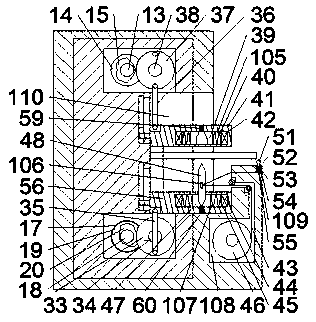

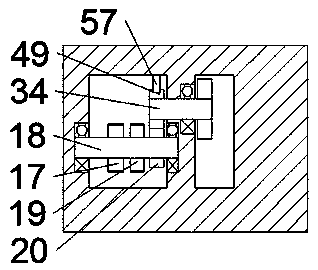

[0022] like Figure 1-Figure 6As shown, a high-efficiency papermaking forming fabric of the present invention includes a fuselage 11 and a first sliding chamber 102 arranged in the fuselage 11, and a left and right sliding cavity is provided in the first sliding chamber 102. The first slider 12, the first slider 12 is provided with a first cavity 101, the first cavity 101 is rotatably provided with a first rotation shaft 22 extending left and right, and the first rotation shaft 22 is right The side end is power-connected with the motor 31 fixedly arranged in the end wall on the right side of the first cavity 101, the left end of the first rotating shaft 22 is fixedly provided with a first pulley 23, and the first cavity 101 The inner rotation is provided with a second rotating shaft 18 extending left and right, and the outer surface of the left side of the second rotating shaft 18 is provided with a second pulley 17, and the transmission between the second pulley 17 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com