Flange type connection structure between top of steel pipe pile and I-beam cross-beam

A technology for connecting structures and I-beams, which is applied in basic structure engineering, sheet pile walls, buildings, etc., to achieve the effect of improving the reuse rate, improving economic benefits and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

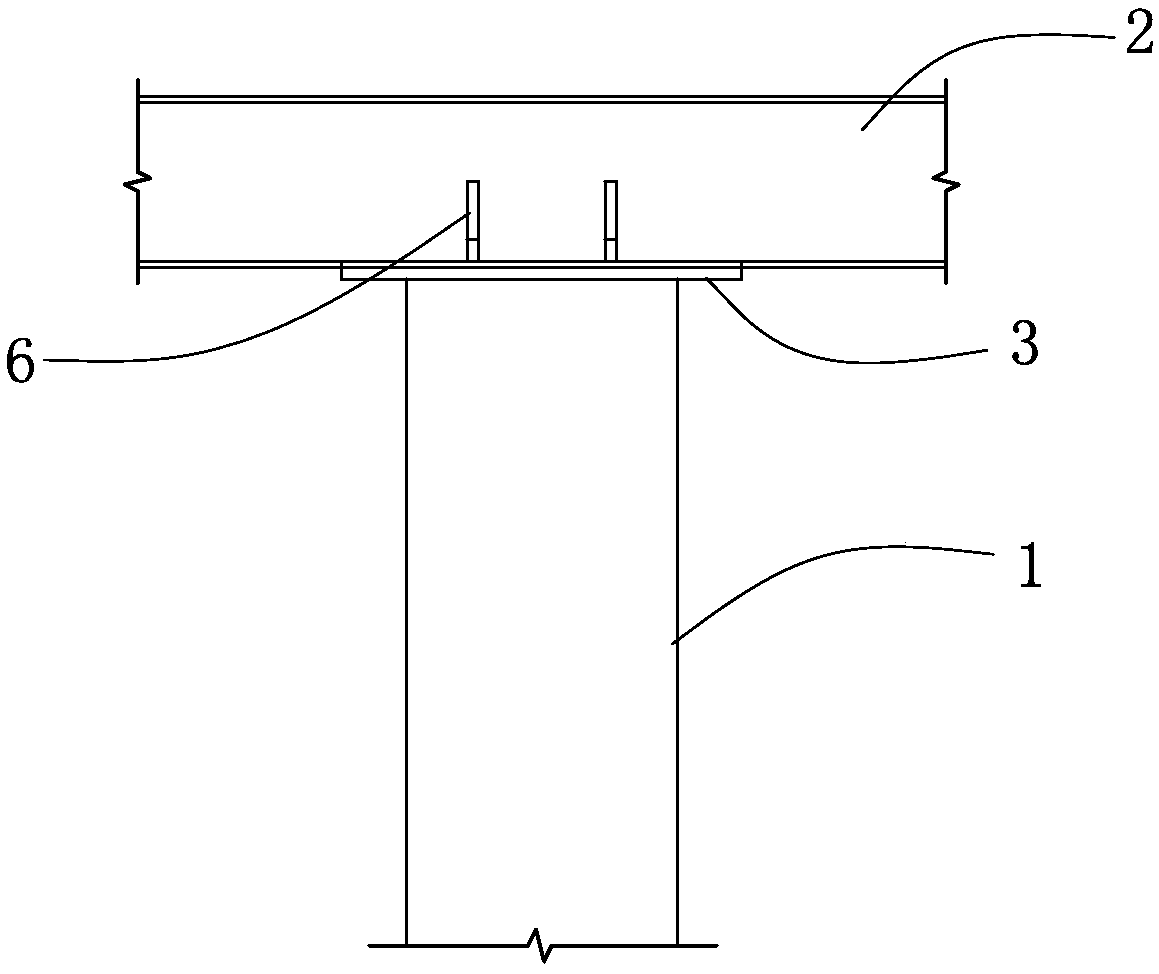

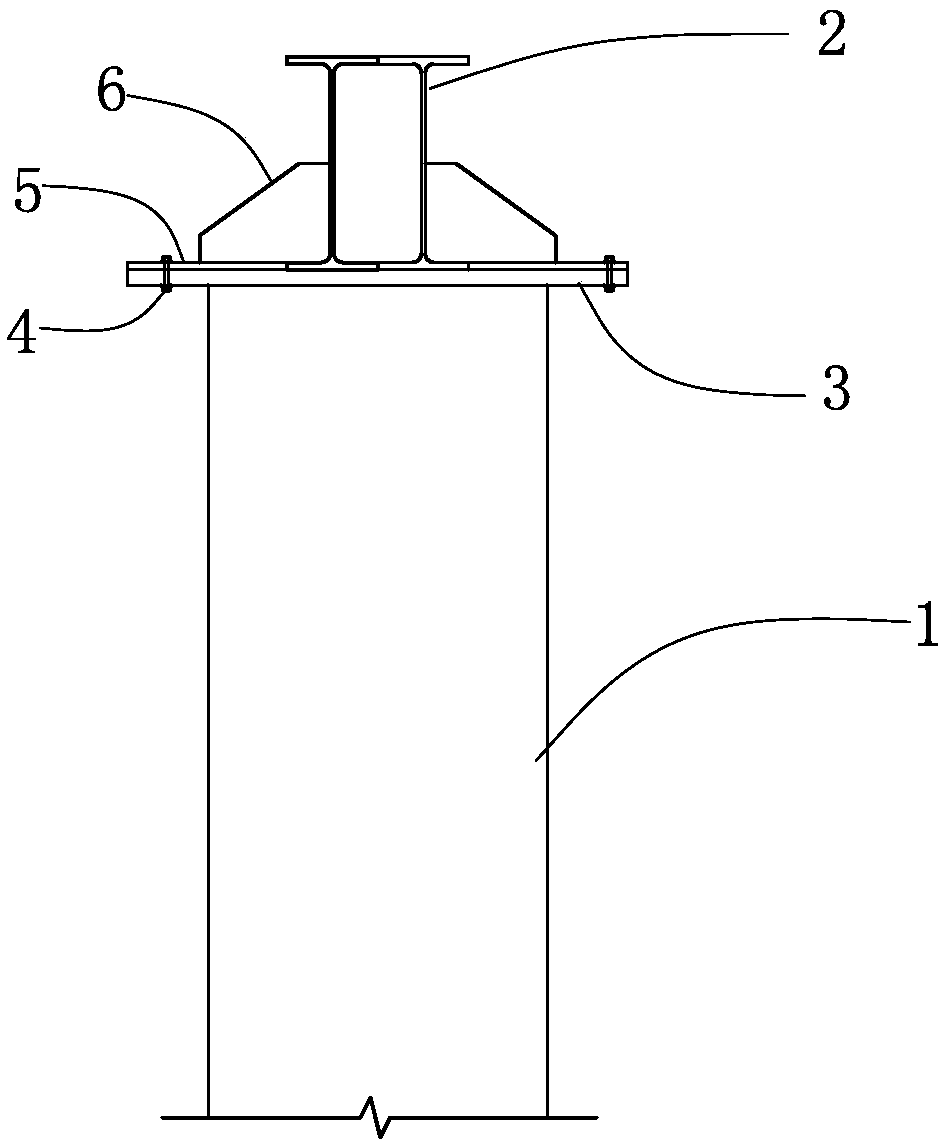

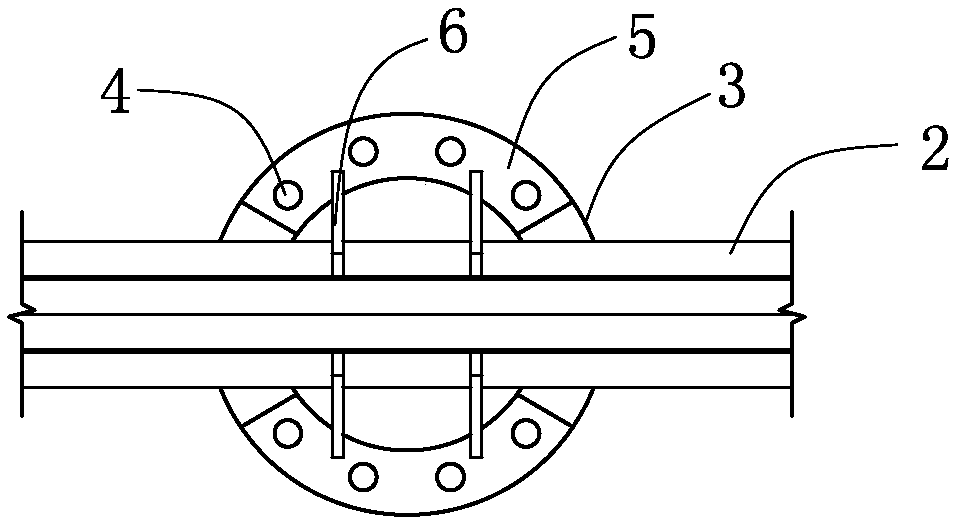

[0014] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a steel pipe pile 1 and an I-beam beam 2 horizontally arranged on the top of the steel pipe pile. The flange plate on the other side is set downward; the top of the steel pipe pile 1 is welded with a fixed flange 3 arranged horizontally, and the structure of the fixed flange is as follows: Figure 4 As shown, screw holes are preset on opposite sides of the fixing flange 3 . The fixed flange 3 connects the two limiting flanges 5 with bolts 4 through screw holes.

[0015] Such as Figure 5 , Image 6 , Figure 7 As shown, each limit flange 5 is a section of arc-shaped steel plate, and each limit flange 5 is provided with an inner arc edge and an outer arc edge, and its radian is equal to the outer peripheral arc radian of the fixed flange 3. Two limit methods 5 The inner arc sides of the two limit flanges are arranged oppositely, and the screw holes corresponding to the fixed flanges a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com