Cast-in place pile reinforcing cage mounting and positioning method and auxiliary device used for cast-in place pile reinforcing cage mounting and positioning method

A technology of bored piles, installation and positioning, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as positioning of reinforcement cages for difficult-to-fill piles, deviation of reinforcement cages for cast-in-place piles, quality and safety hazards, etc., to achieve Safe and reliable working performance, improving construction efficiency, improving quality and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

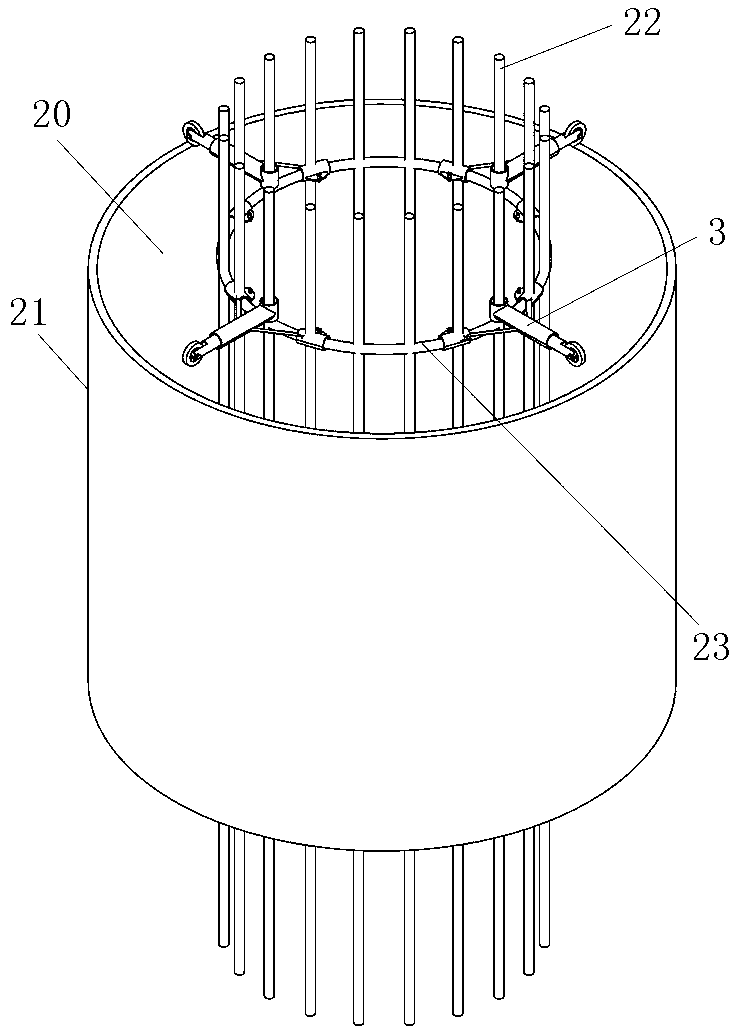

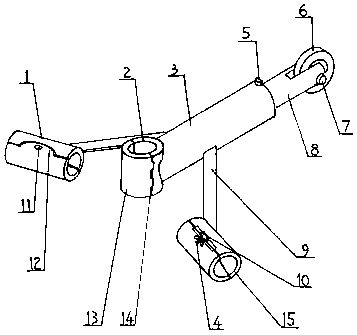

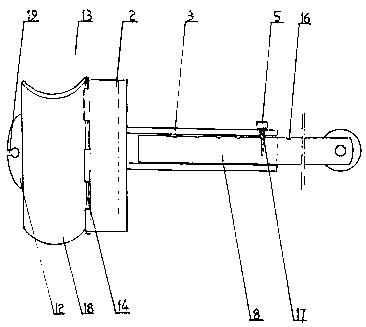

[0036] Such as Figure 1 to Figure 3 Shown, a kind of auxiliary device that realizes the installation and positioning method of the reinforced cage of the bored pile, the auxiliary device is a positioning bracket, and the positioning bracket is composed of a first fixed sleeve 1, a second fixed sleeve 15, The supporting rod 9, the intermediate casing 13, the pipe body 3, the telescopic pipe 8, the fixed latch 5 and the roller 6 are formed. The rear end of the pipe body is provided with an intermediate sleeve. The rear end of the telescopic tube is inserted into the front end of the tube body. The inner wall of the pipe body is slidingly matched with the outer wall of the telescopic pipe, so that the telescopic pipe is pulled out or retracted into the pipe body conveniently.

[0037] The rear upper end of the telescopic tube is provided with several adjustment holes 16 distributed at intervals from the rear to the front. A fixing hole 17 is provided on the upper front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com