A dry splicing structure of floor tiles and its splicing method

A floor tile, dry-type technology, applied in the direction of building structure, building, floor, etc., can solve the problems of complex floor tile laying technology, environmental impact of construction conditions, and difficulty in guaranteeing construction quality, and achieves good splicing quality and construction efficiency. High, easy splicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

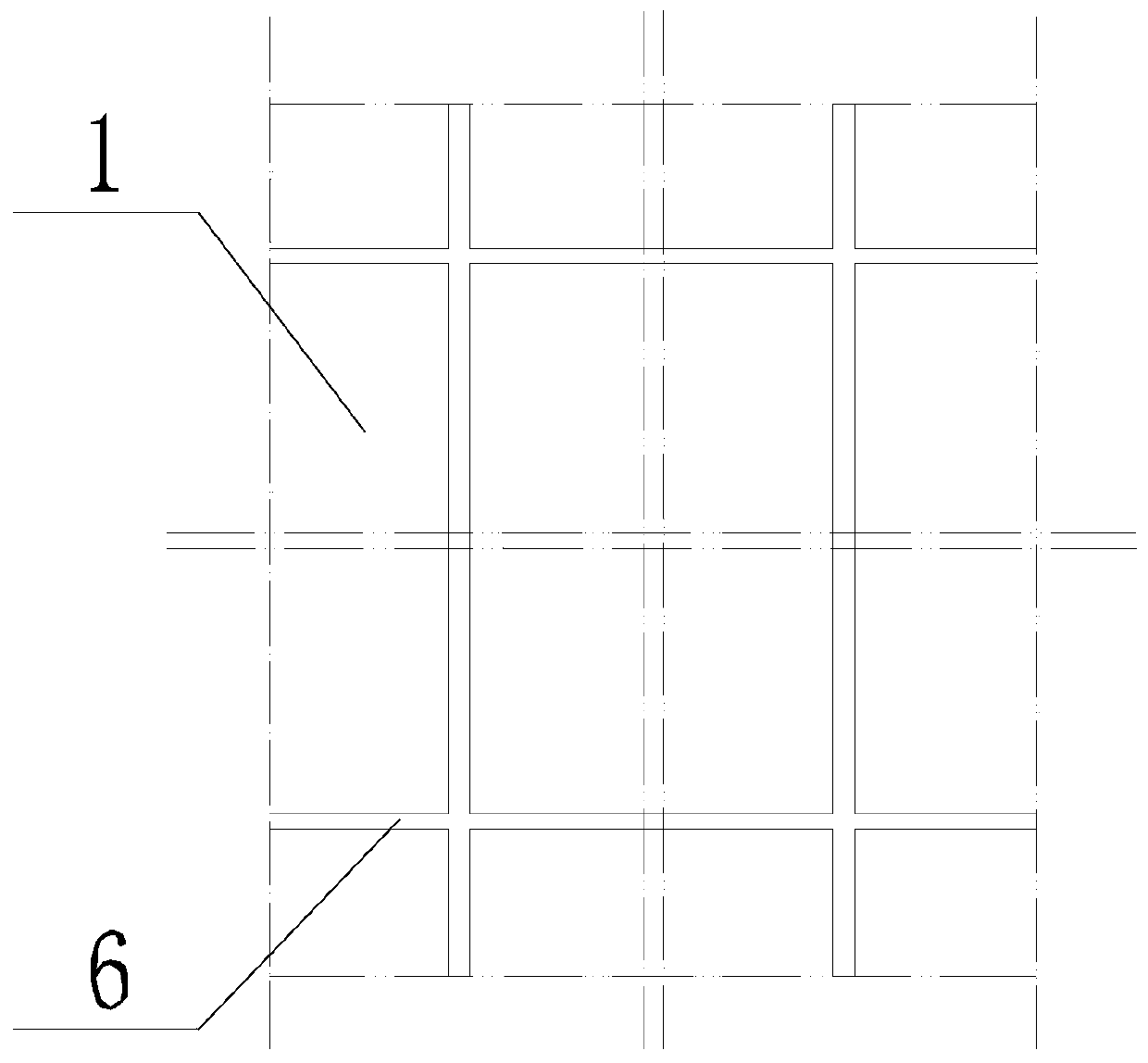

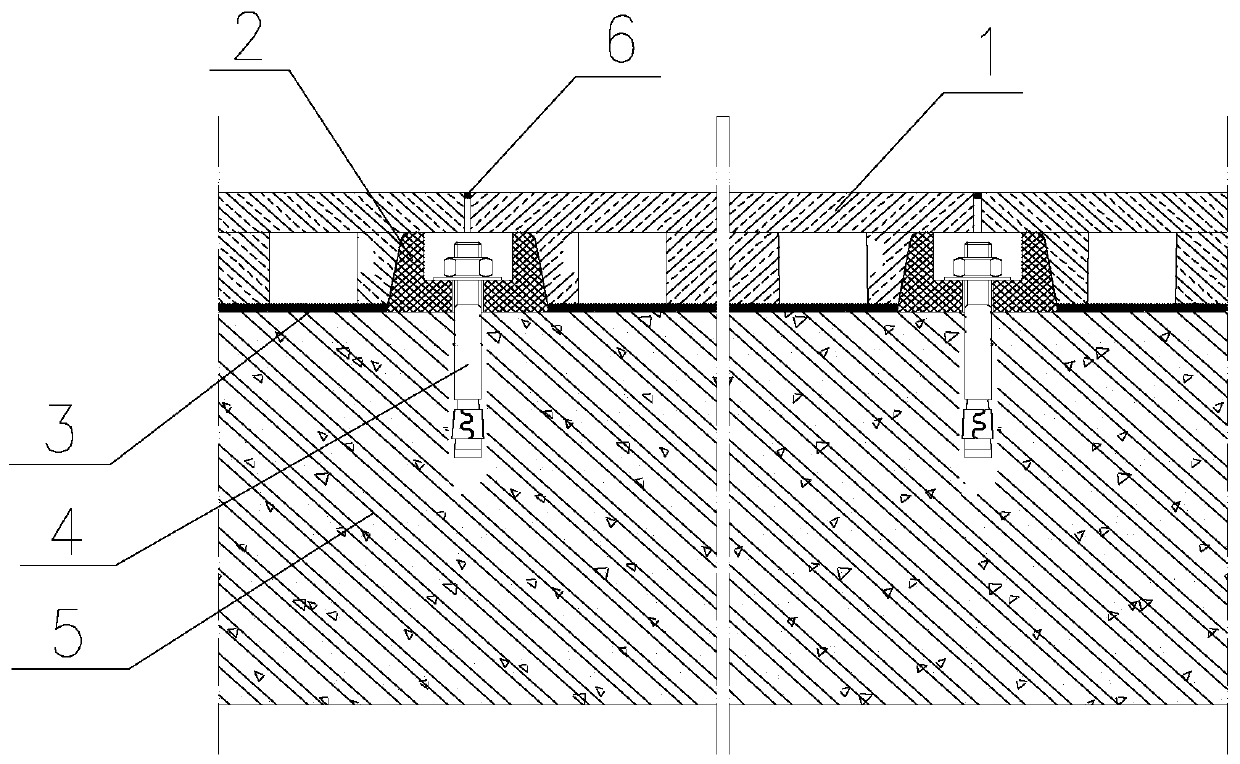

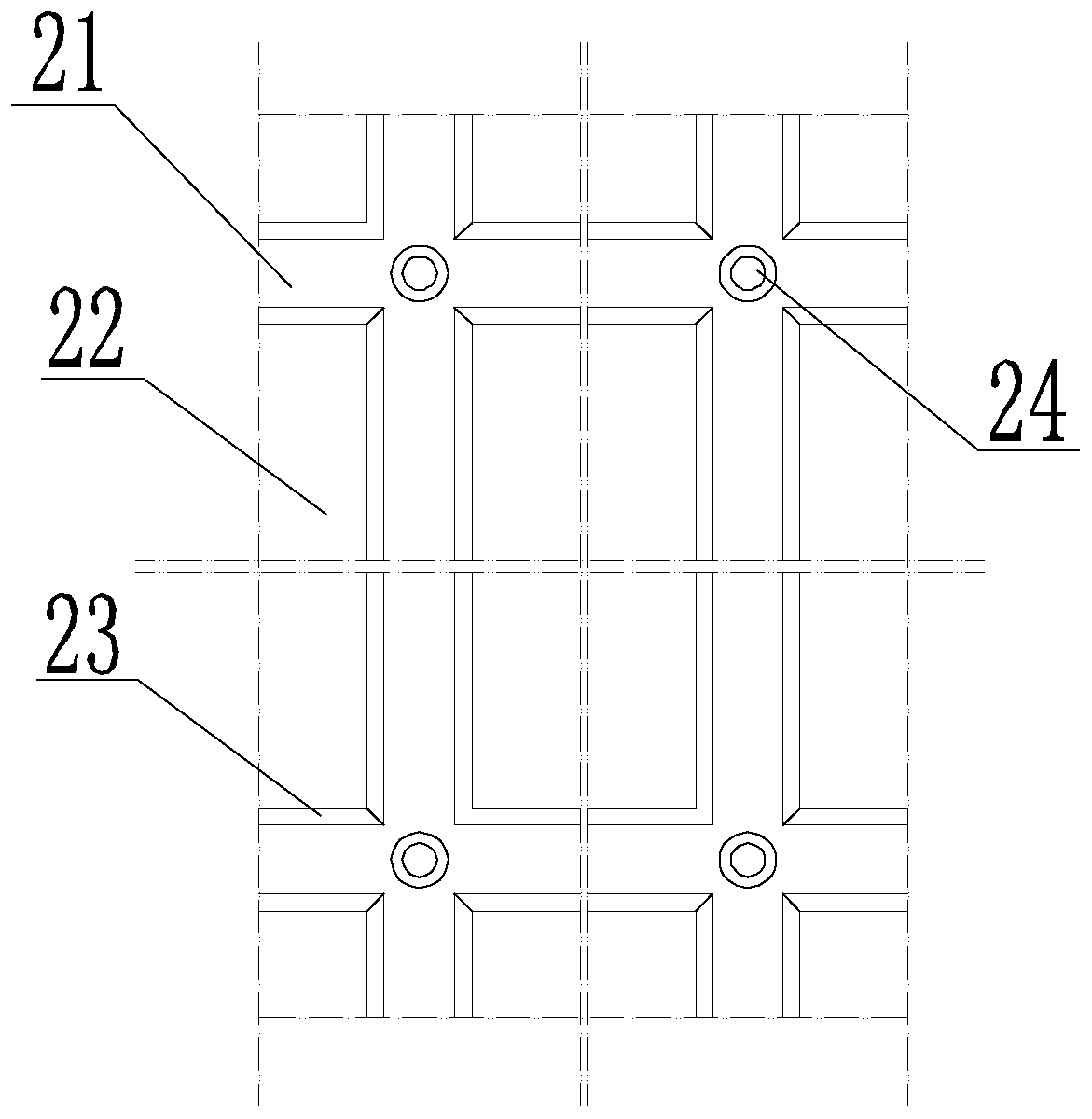

[0026] See attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , a dry splicing structure of a floor tile 1 according to the present invention, comprising a paving surface 5, a support frame 2 is provided on the paving surface 5, floor tiles 1 are laid on the support frame 2, and caulking strips 6 are provided between adjacent floor tiles 1 The support frame 2 includes a mounting surface 21 and a mounting groove 22, the support frame 2 is provided with a plurality of mounting grooves 22, the support frame 2 is provided with a mounting surface 21 on the circumference of the mounting groove 22, and the mounting surface 21 is provided with a card groove 23 The floor tile 1 includes a connecting plate 11 and a protrusion 13. The back of the floor tile 1 is provided with a protrusion 13 snapped into the installation groove 22. The connecting plate 11 is located in the circumferential direction of the floor tile 1 and abuts against the installation su...

Embodiment 2

[0033] A splicing method of a floor tile 1 dry type splicing structure of the present invention comprises the following steps: 1) selecting a paving surface 5, and connecting the support frame 2 on the paving surface 5 by the above method; 2) splicing the floor tile 1 on the support frame 2. In this embodiment, the laying surface 5, the support frame 2 and the floor tile 1 all have the structure described in the first embodiment, the laying surface 5 is connected to the support frame 2 through the expansion bolt 4, and the support frame 2 is connected to the support frame 2 through the installation groove 22 and the protrusion 13 As well as the cooperating splicing of the card slot 23 and the card block 12 to connect the floor tile 1, the present invention is a dry splicing method in the true sense. The construction process is simple, the construction efficiency is high, and it is not limited by the ambient temperature. The gap between them is even, the surface is flat, the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com