Aluminum alloy electric heating floor and connecting plate thereof

A technology of aluminum alloy and connecting plate, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of insufficient heat dissipation of the electric heating floor, warping of the electric heating floor, poor load-bearing capacity, etc., and achieves simple structure and low cost. Inexpensive, easy-to-splice effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

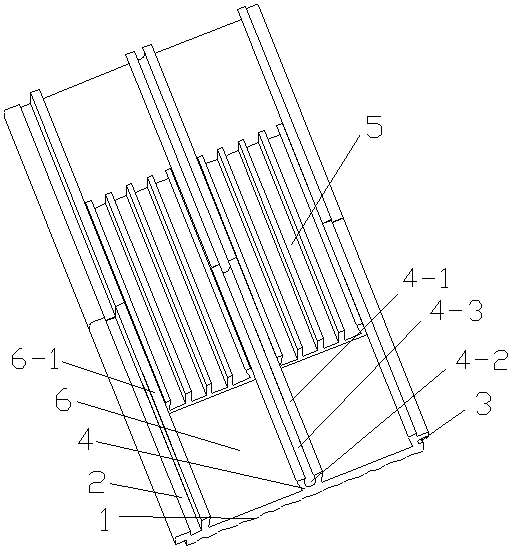

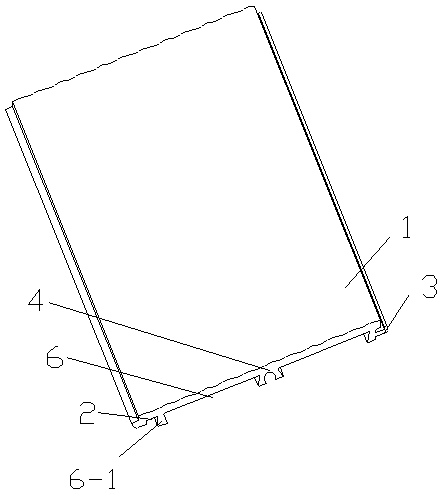

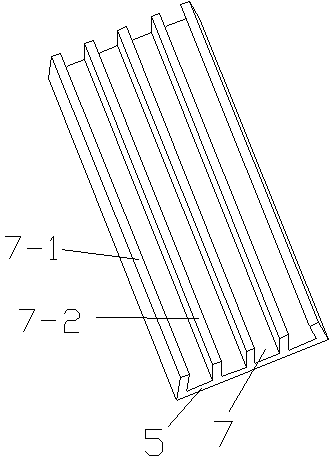

[0014] Such as Figure 1-2 As shown, an aluminum alloy electric heating floor, the electric heating floor surface 1 is wavy, and the wavy surface can increase the load-bearing capacity and anti-slip performance of the electric heating floor, and one edge of the floor is provided with a card slot 2. The edge of the other side is provided with a clamping part 3 that is compatible with the card slot 2. In the middle of the bottom surface of the floor is provided a heat conduction groove 4 for installing heat conduction fibers. The groove 6, the trapezoidal groove 6 is formed by the heat conduction groove edge 4-1 of the heat conduction groove 4 being inclined to the same side with the corresponding floor edge groove edge 6-1 at the floor edge, wherein the floor edge groove edge 6 at the floor edge -1 is respectively connected with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap