Dry-type drilling dust removal system and dust removal method thereof

A dust removal system, dry technology, applied in the direction of non-volume pumps, machines/engines, mechanical equipment, etc., can solve the problems of poor applicability, high cost, and complex structure in the downhole environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

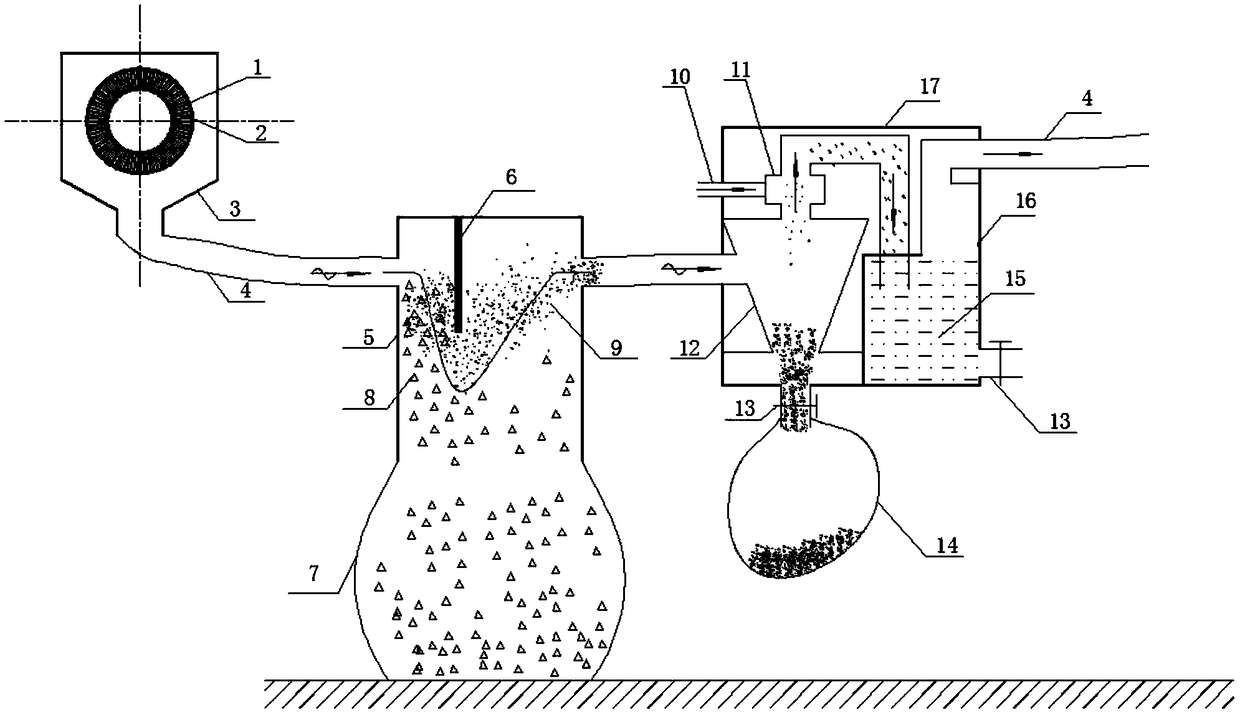

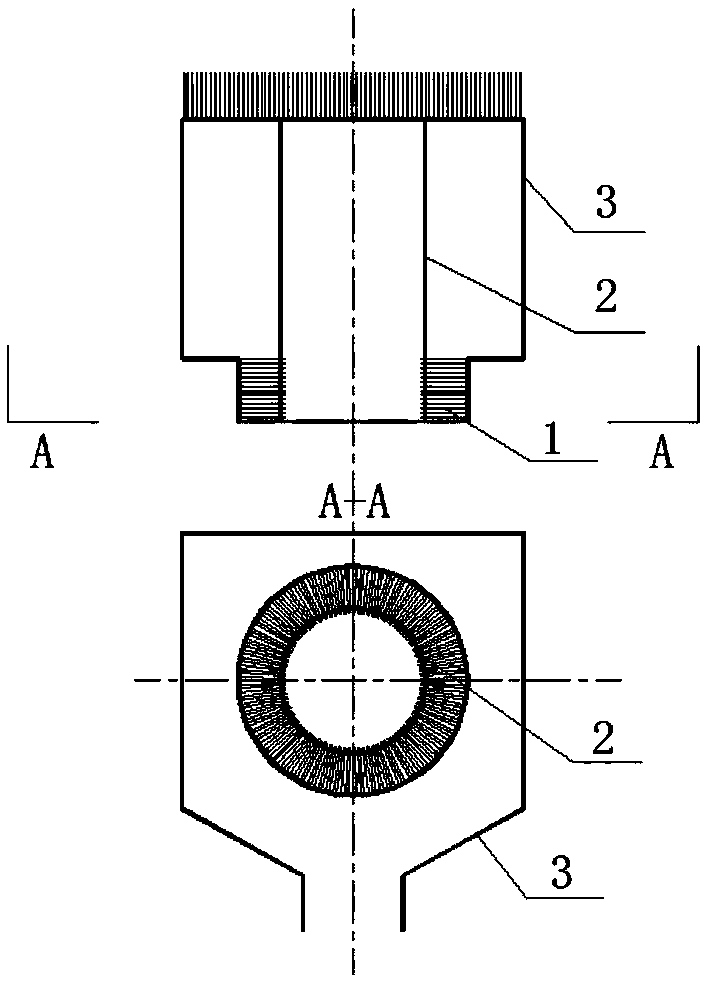

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the dust collector in the present invention, as shown in the figure, the dust removal system for drilling dry drilling in this embodiment; it includes a dust collector, which is sequentially connected to the dust collector arranged at the rear end of the dust collector. Separator, multi-stage dust collector and negative pressure device for driving the flow of dust-laden gas; the dust collector includes a cylindrical shell-shaped cover body 3 that is covered on the drill pipe 2, and the front end of the cover body 3 is open And the front end face is provided with a front end flexible sealing ring (not marked) which is composed of flexible temples along the circumferential direction of the drill pipe, and the rear end face of the cover is provided with a drill pipe through hole, and the inner wall of the drill pipe through hole is provided with a flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com