Device and method for detecting push-pull force and torque of horizontal section of coiled tubing used in experiments

A detection method and detection device technology, which are used in surveying, earthwork drilling, wellbore/well components, etc., can solve the problem of lack of real-time detection methods for coiled tubing specimens, inability to perform real-time detection of specimens, and low accuracy of detection methods. problems, to achieve the effect of improving work efficiency, good reference significance, and guiding on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. In the range.

[0036] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present inventi...

Embodiment 1

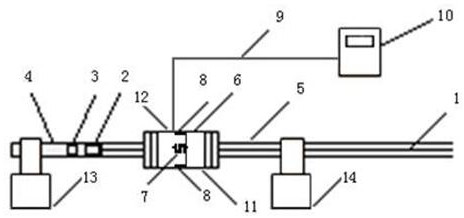

[0038] Such as Figure 1~8 As shown, a test method for testing the push-pull force and torque of the horizontal section of coiled tubing includes the following steps:

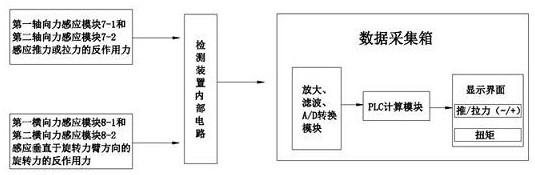

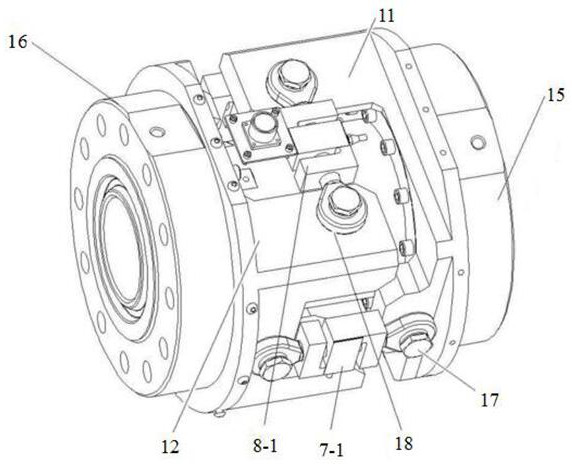

[0039] Step 1: Simulate the drilling process, the test piece 3 is pushed to the left by the coiled tubing 1 through the downhole tool 2, the experimental casing 4 and the moving mechanism 12 generate tension, and the moving mechanism 12 and the anchoring mechanism 11 in the detection device 6 are pushed to the left. In the sealed state, there is an axial relative displacement trend, and the axial force sensing module 7 senses the reaction force of the two thrusts on the moving mechanism 12, and then indirectly senses the reaction force of the two thrusts on the test piece 3, and passes through the detection device 6. After the piezoelectric conversion of the circuit, the signal is picked up, transmitted through the data line 9, and then calculated and displayed by the data acquisition box 10. During the calcula...

Embodiment 2

[0043] Such as Figure 1~8 As shown, a test method for testing the push-pull force and torque of the horizontal section of coiled tubing includes the following steps:

[0044] Step 1: Simulate the drilling process, the test piece 3 is pushed to the left by the coiled tubing 1 through the downhole tool 2, the experimental casing 4 and the moving mechanism 12 generate tension, and the moving mechanism 12 and the anchoring mechanism 11 in the detection device 6 are pushed to the left. In the sealed state, there is an axial relative displacement trend, and the axial force sensing module 7 senses the reaction force of the two thrusts on the moving mechanism 12, and then indirectly senses the reaction force of the two thrusts on the test piece 3, and passes through the detection device 6. After the piezoelectric conversion of the circuit, the signal is picked up, transmitted through the data line 9, and then calculated and displayed by the data acquisition box 10. During the calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com