Compressor rotor and compressor containing same

A compressor rotor and rotor core technology, which is applied in the field of compressors, can solve problems such as insignificant flow effects, reduced compressor efficiency, and limited area, and achieve the effects of improving oil return effects, increasing flow rates, and accelerating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

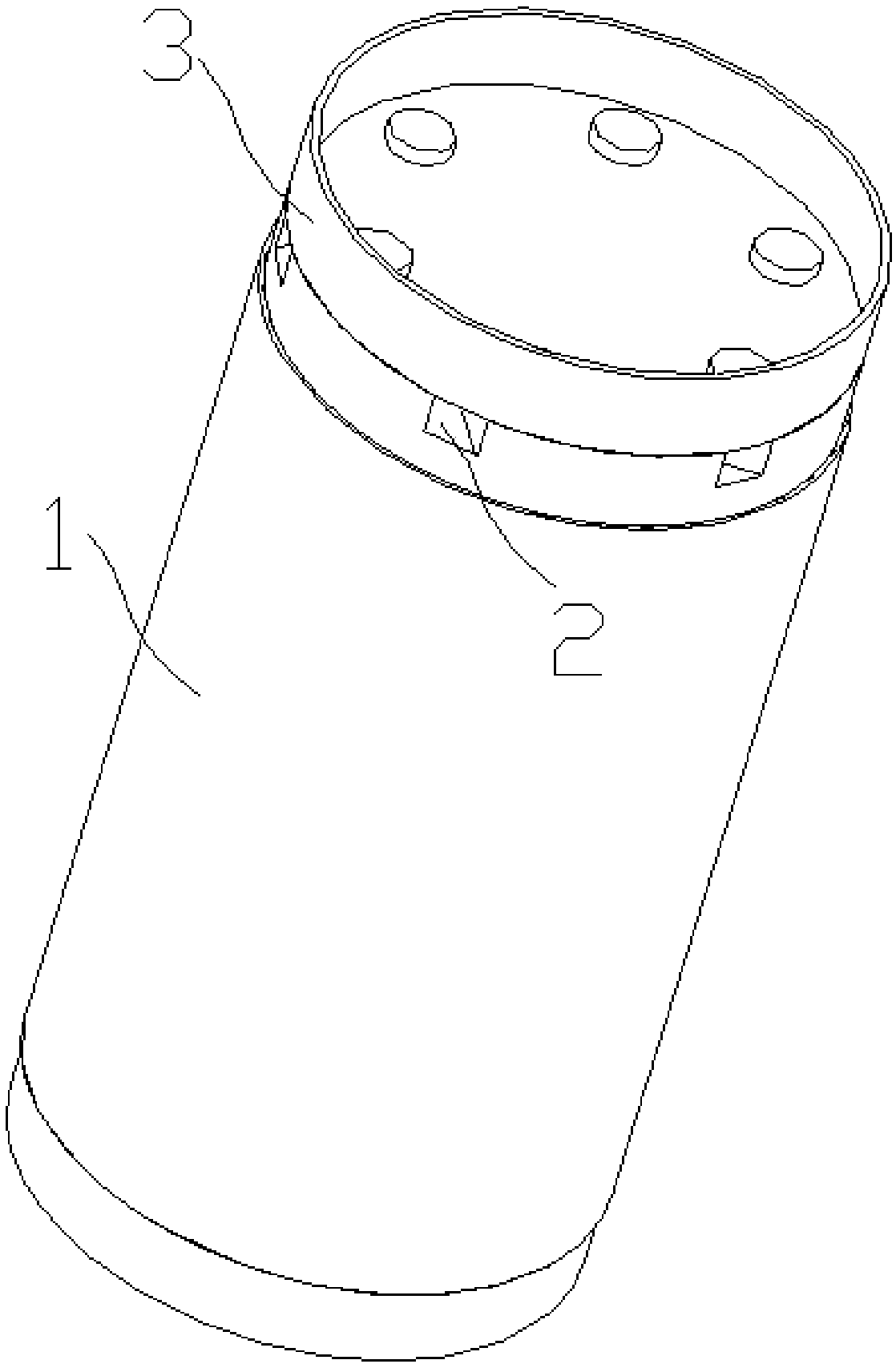

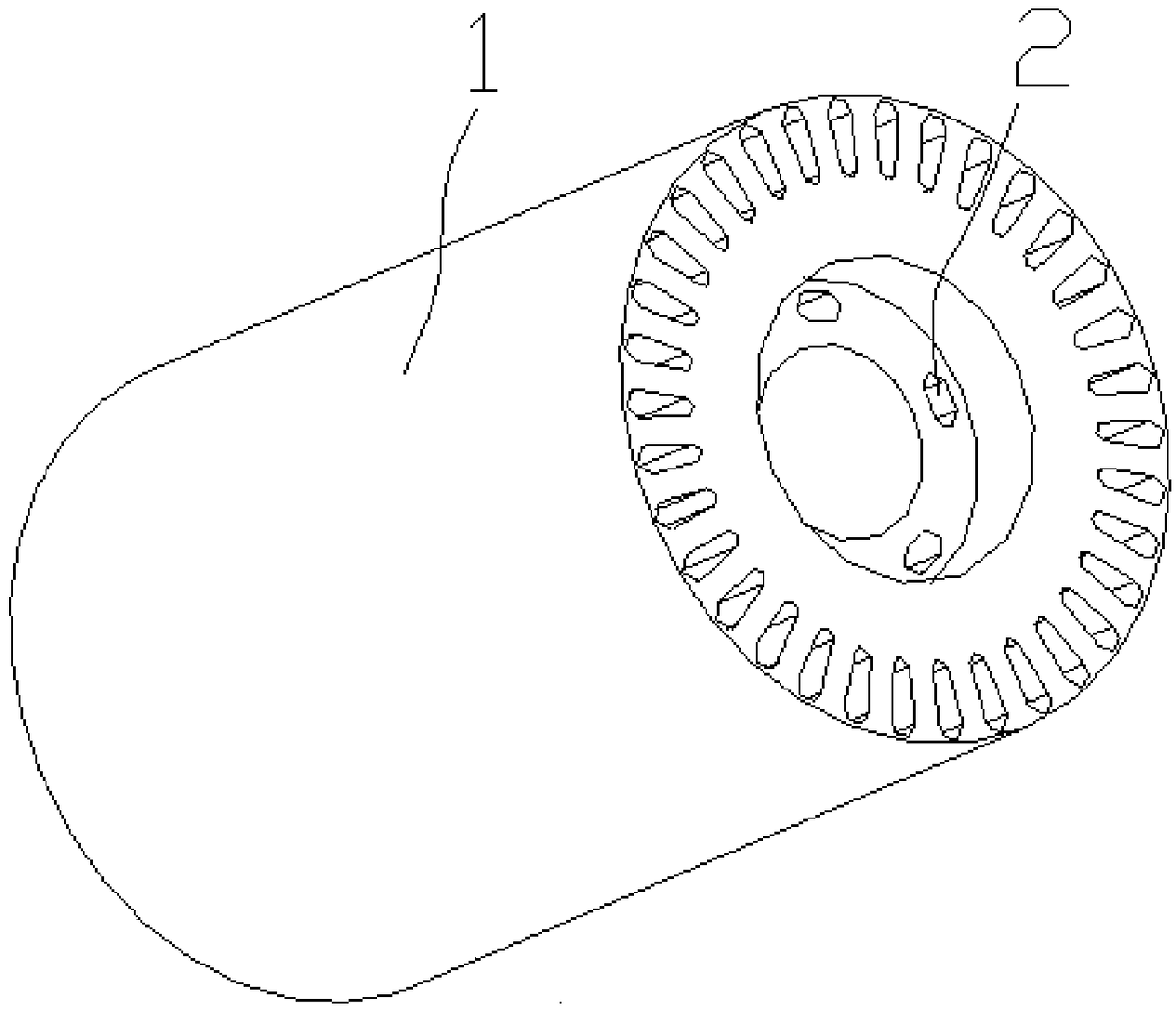

[0036] Please refer to figure 1 , combined with figure 2 -4, this embodiment provides a compressor rotor, including a rotor iron core 1, the rotor iron core 1 is provided with a circulation hole 2 for the circulation of refrigerant, and one end of the rotor iron core 1 is connected with a lower end ring; The other end is connected with a guide structure 3 for guiding the refrigerant to be discharged from the radial direction of the rotor core;

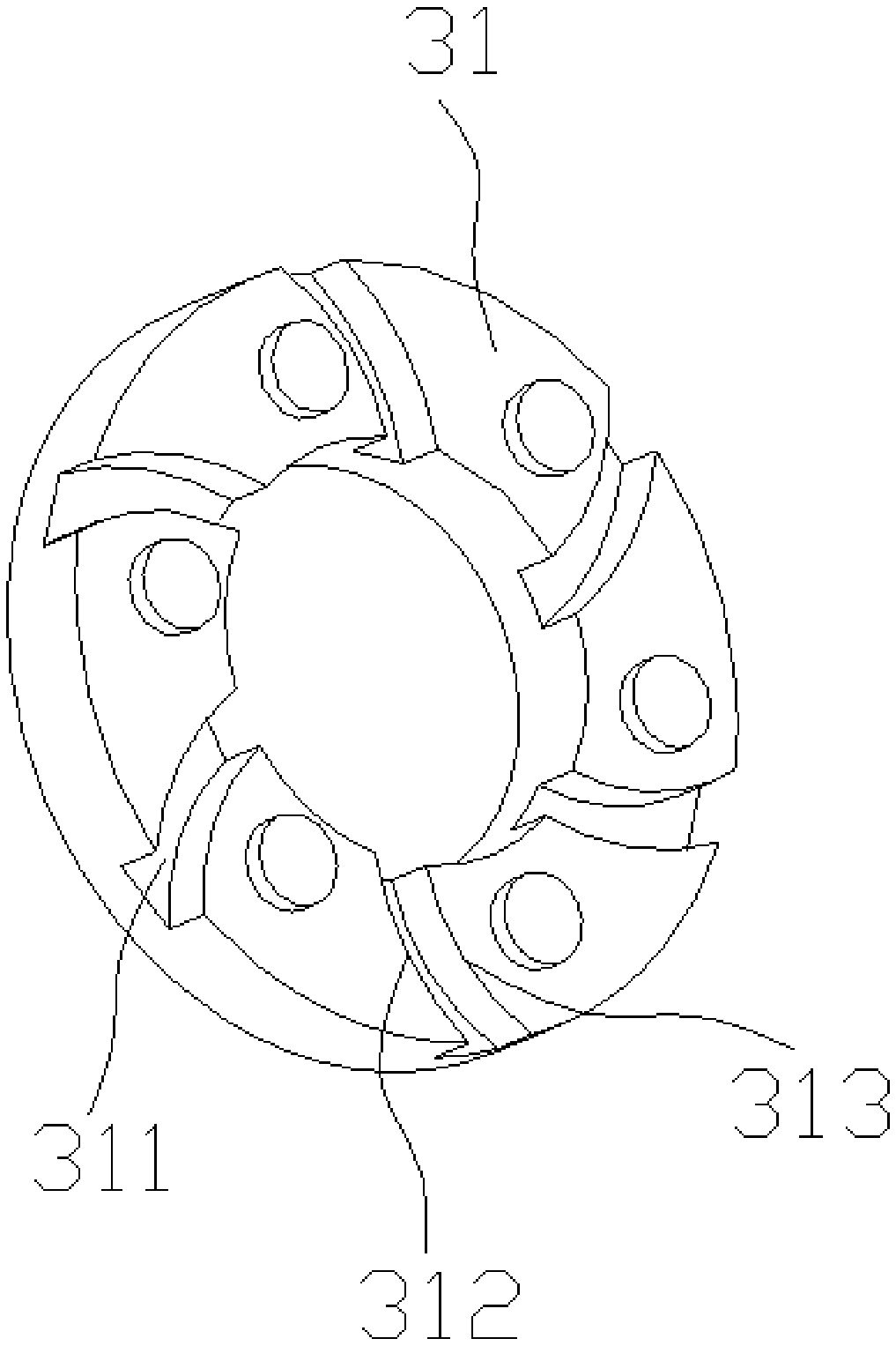

[0037] The diversion structure 3 is provided with one or more flow channels connected with the circulation holes 2 toward the outer peripheral side of the rotor core 1, and the flow channels are used for the circulation of refrigerant; the side of the diversion structure 3 connected with the rotor core 1 is provided with an end The end hole does not penetrate the flow guide structure 3, the end hole covers the flow hole 2 and the axial hole of the rotor, and the flow channel communicates with the end hole.

[0038] The diversion str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com