Strip steel online surface defect detection system and detection method thereof

A defect detection and detection method technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of economic losses of enterprises, the impact of strip steel surface quality, and the inability to meet automatic online detection, etc., to achieve quality control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0026] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

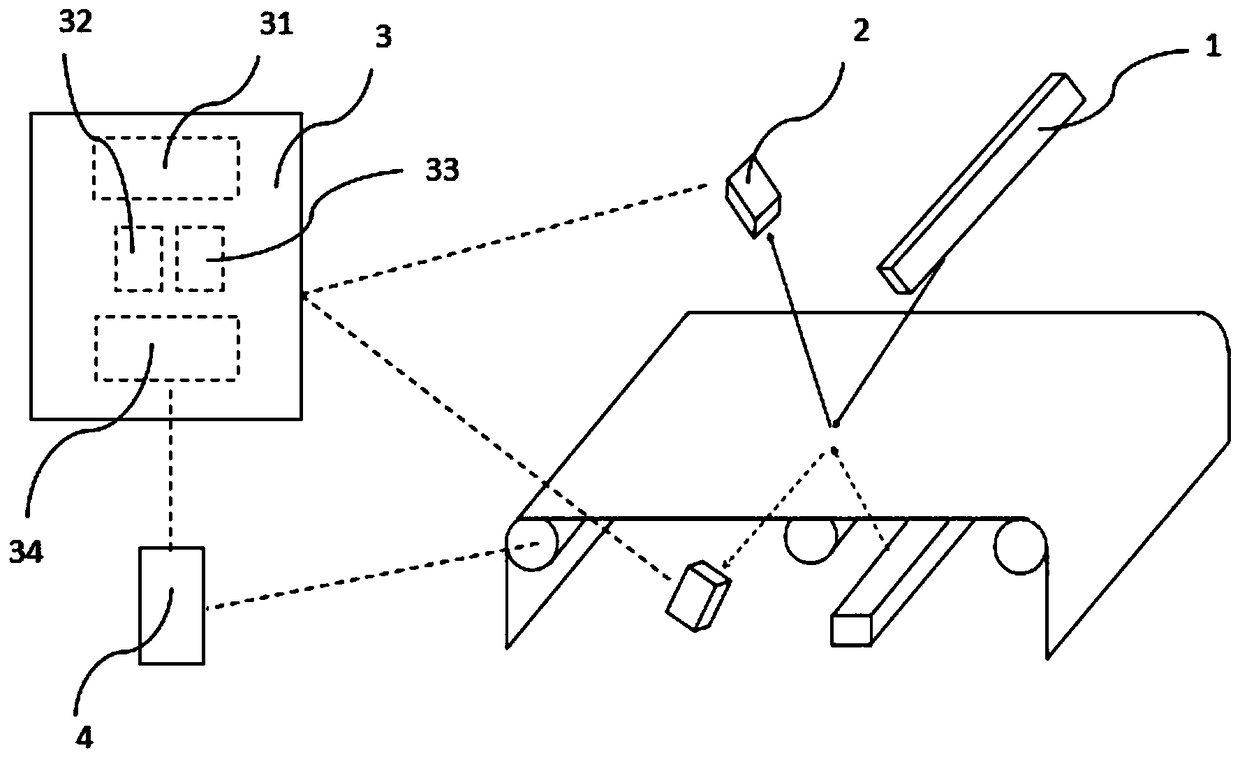

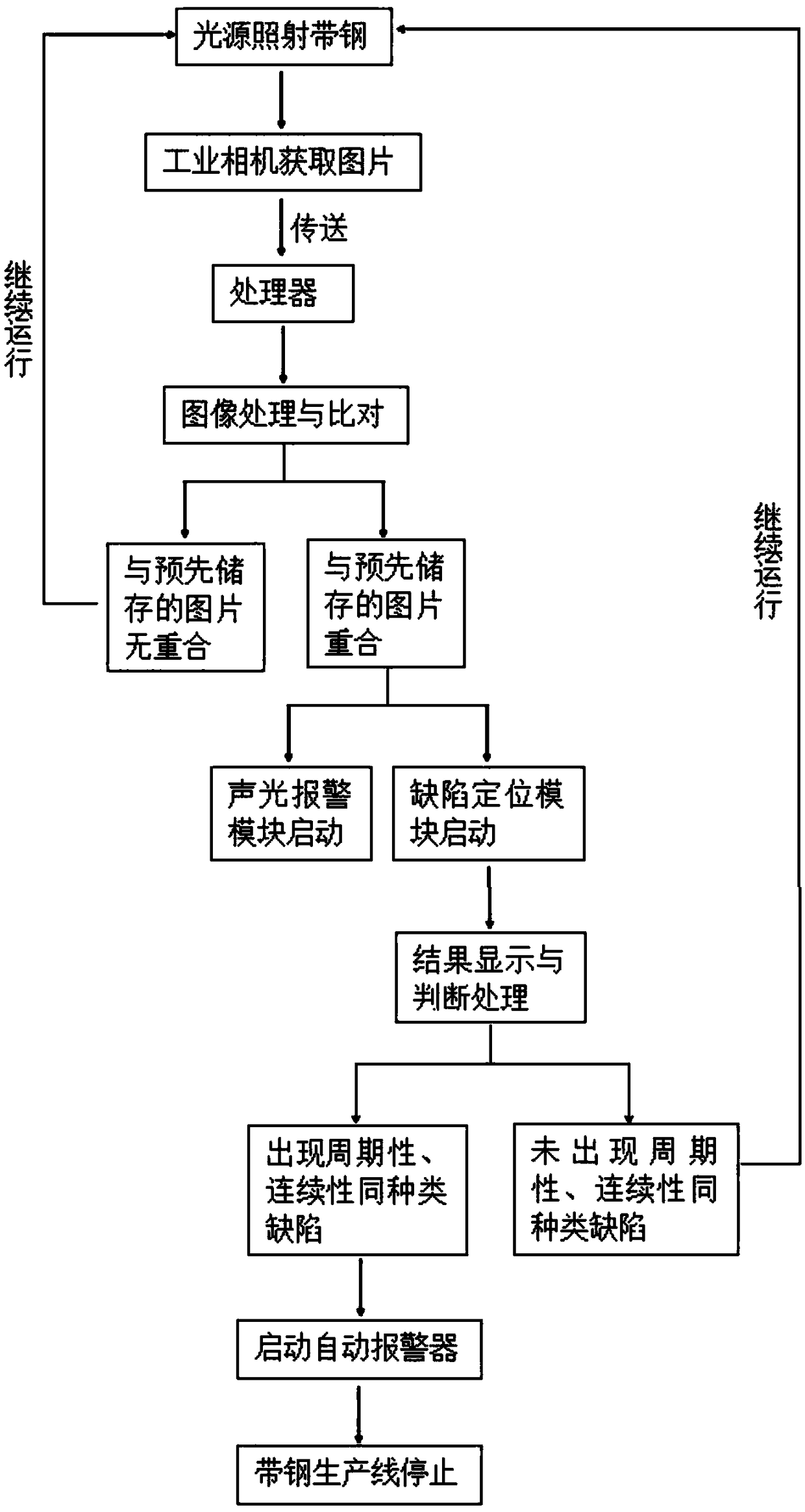

[0027] Such as Figure 1-2 As shown, the strip steel online surface defect detection system includes a light source 1, an industrial camera 2, a processor 3 and an automatic alarm 4, the detection system is connected with the strip steel production line, and the processor 3 includes images connected sequentially by wireless Defect identification module 31, sound and light alarm module 32, defect location module 33, result display and judgment processing module 34, described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com