Automatic synchronous servo multi-axis tapping device for high-precision parts

A technology of automatic synchronization and parts, applied in the direction of thread cutting device, thread cutting feeding device, sorting, etc., can solve the problems of production capacity and cost that cannot meet the expected requirements, low utilization rate of personnel and equipment, etc., and achieve the control of production capacity and quality , High utilization rate of equipment, cost optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

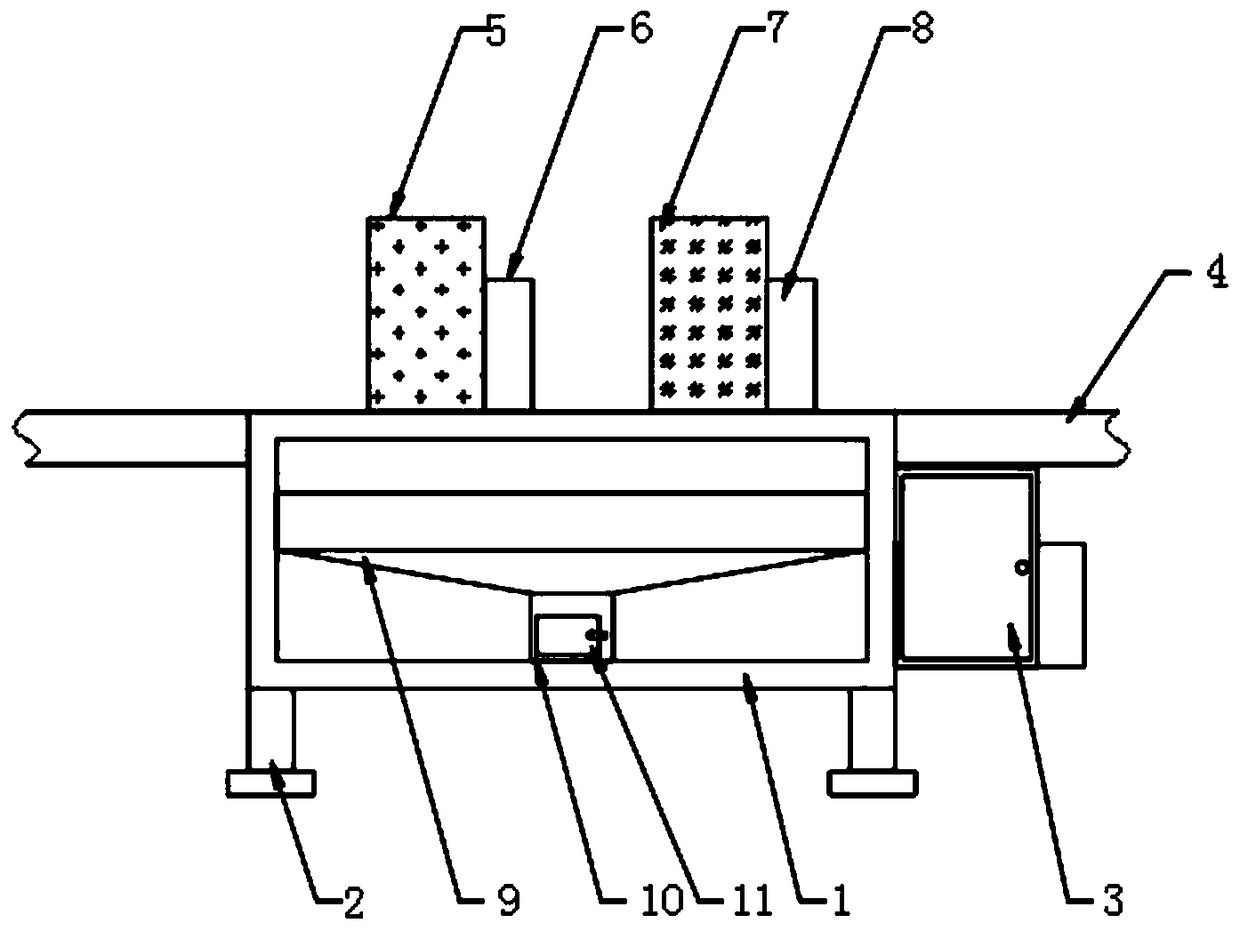

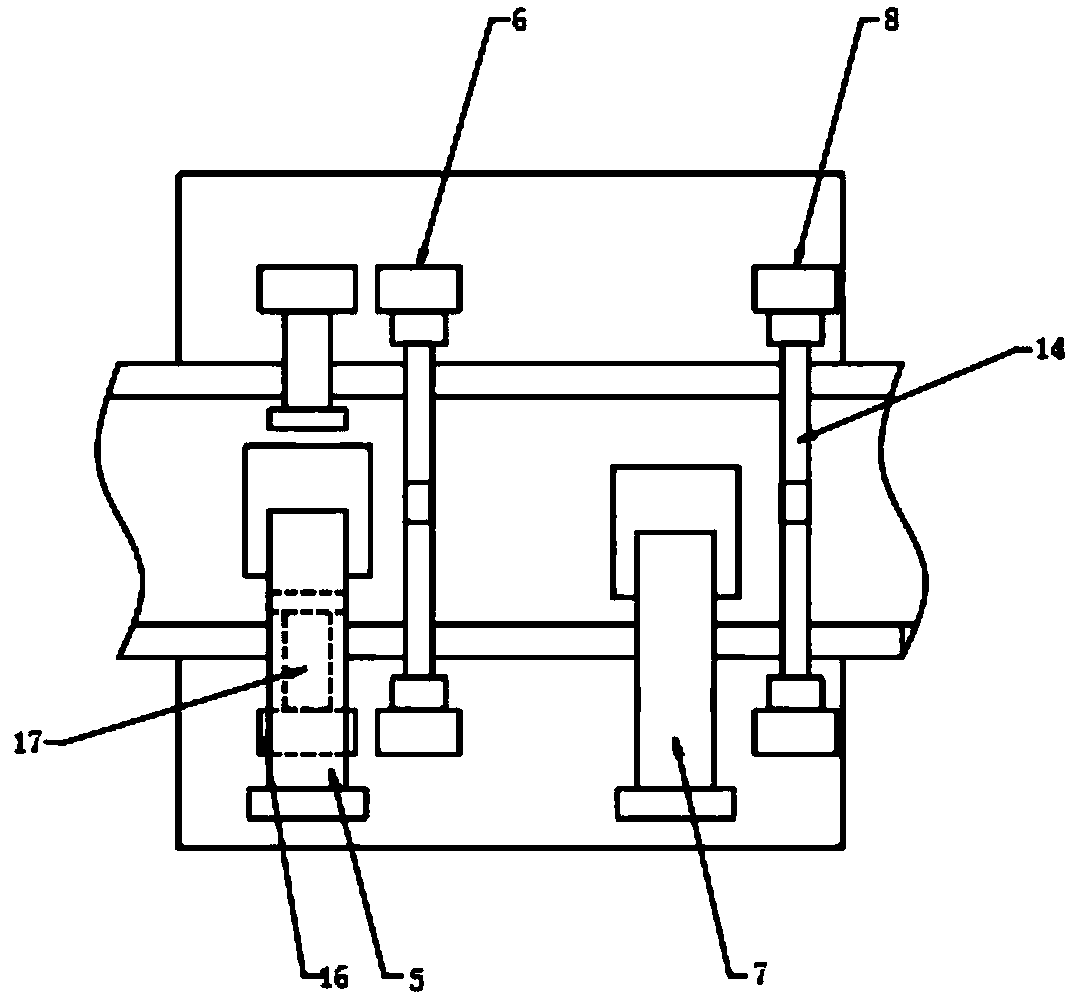

[0022] Embodiment one, by figure 1 , figure 2 and image 3 Provide, the present invention comprises device base 1, and the four jiaos of device base 1 bottom are all equipped with support leg 2, and one end of device base 1 is connected with electric control box 3, and the top of device base 1 is embedded and connected with conveyor belt 4;

[0023] The both sides of conveyer belt 4 first ends are all provided with first support 16, and first support 16 is equipped with the compression cylinder 17 that is used for fixing workpiece toward the side of conveyer belt 4, and the first support 16 is provided with tapping away from the side of conveyer belt 4. dental machine 5;

[0024] The side of the first support 16 is also provided with a first blocking mechanism 6 for blocking the advancement of the workpiece, and the first blocking mechanism 6 is also provided with a detection mechanism 7 away from the side of the first support 16, and the detection mechanism 7 is far away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com