Robot system for automatically detecting surface material of switch cabinet bus

A robot system and automatic detection technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as low work efficiency, achieve the effect of ensuring safety and quality, and preventing mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be further described below. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

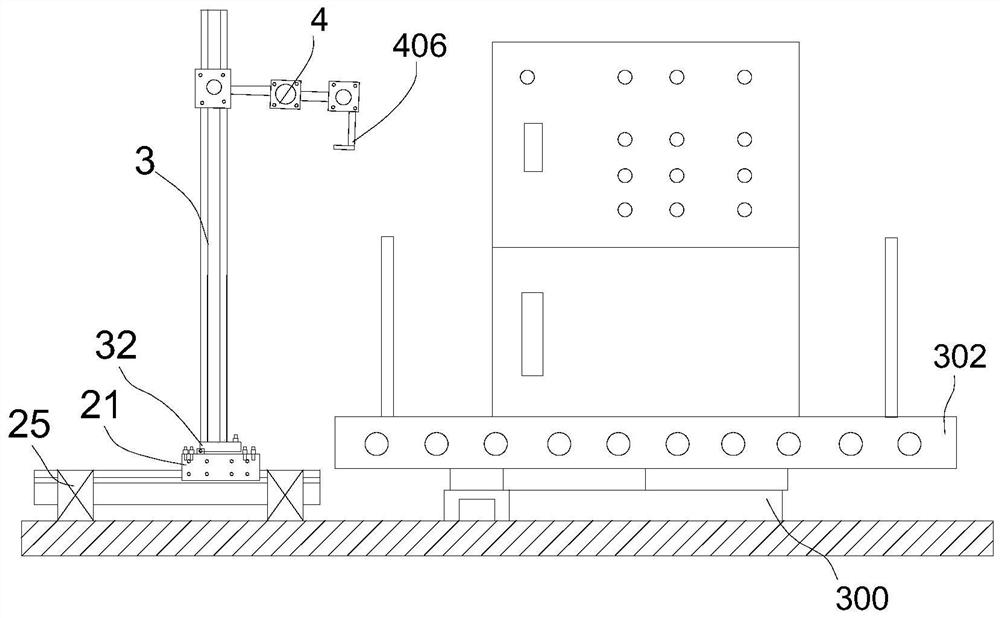

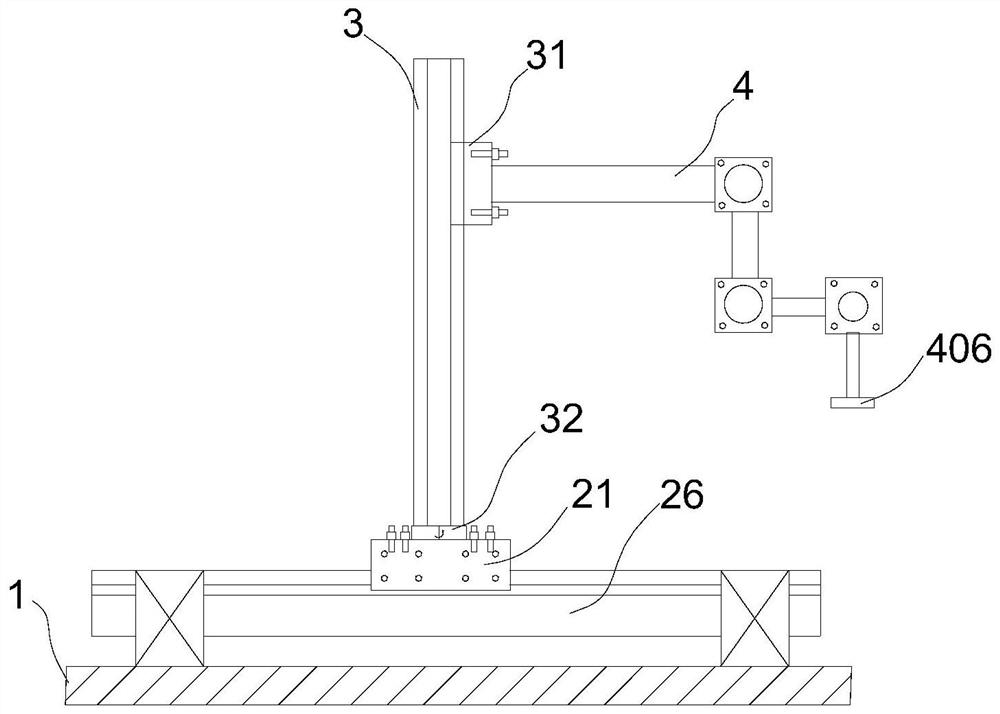

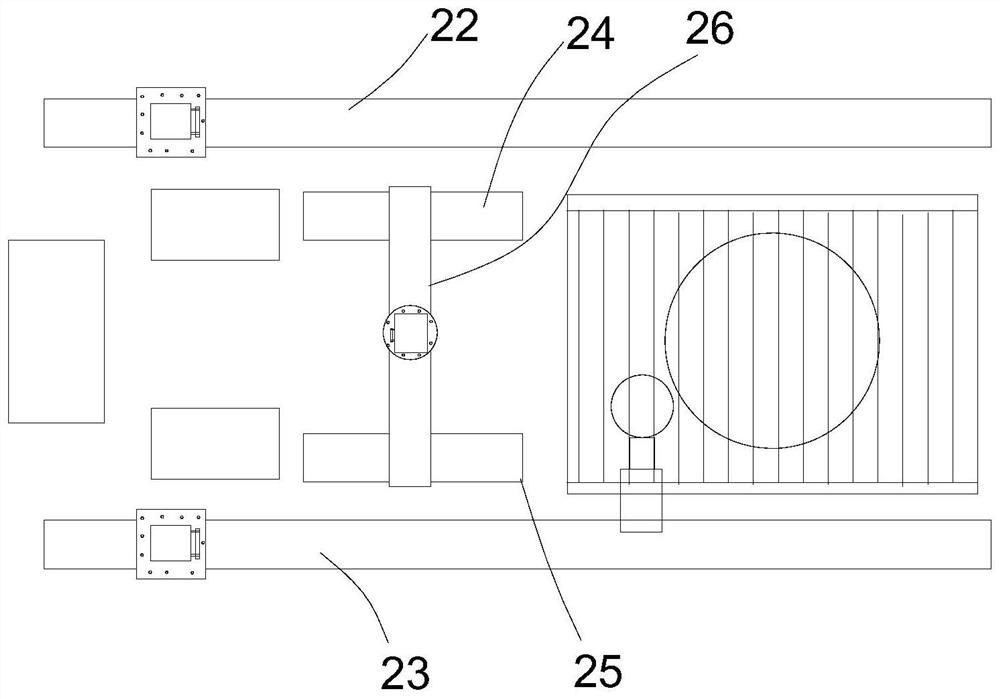

[0029] as attached Figure 1~4 As shown, a robot system for automatic detection of the surface material of the switchgear busbar, including a four-degree-of-freedom mobile platform that can move in three vertical directions and one rotational direction, an industrial robot 4, and a material inspection instrument installed at the operating end of the industrial robot 406:

[0030] The four-degree-of-freedom mobile platform includes a third horizontally movable guide rail 24 and a fourth horizontally movable guide rail 25 arranged in parallel to form a longitudinal horizontal linear guide rail;

[0031] The slide block on the third horizontally moving guide rail 24 and the fourth horizontally moving guide rail 25 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com