Large-area luminescence electrochemical cell device and preparation method thereof

A light-emitting electrochemical cell and large-area technology, which is applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, and electrical components, can solve the problems of low material utilization rate and unsuitable for large-area device preparation, and reduce production costs. Quality and performance, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

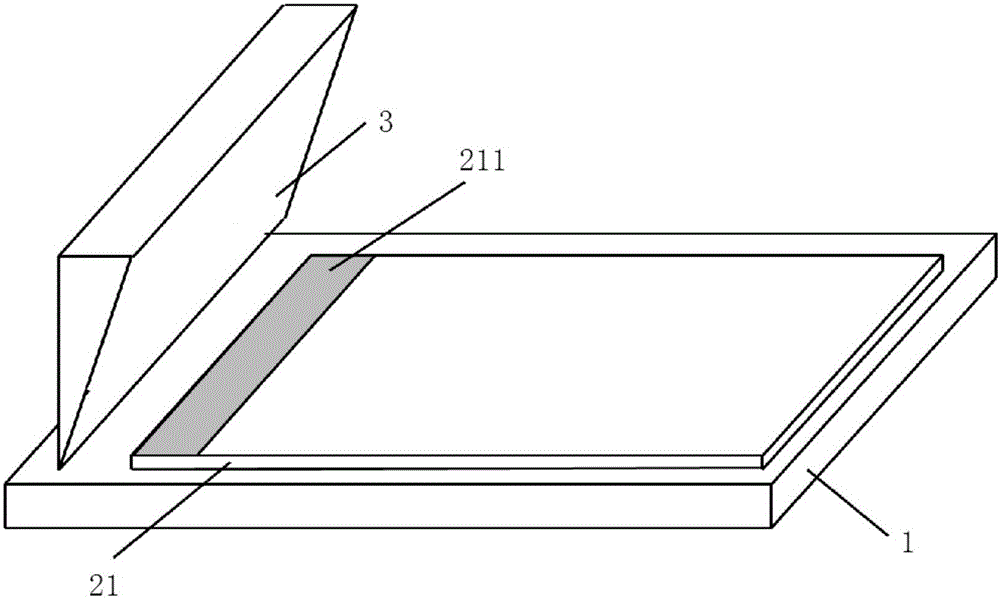

[0016] An embodiment of the present invention provides a method for preparing a large-area light-emitting electrochemical cell device, comprising the following steps:

[0017] S01. Provide a fixed substrate with a heating function, and fix a transparent conductive base on the fixed substrate;

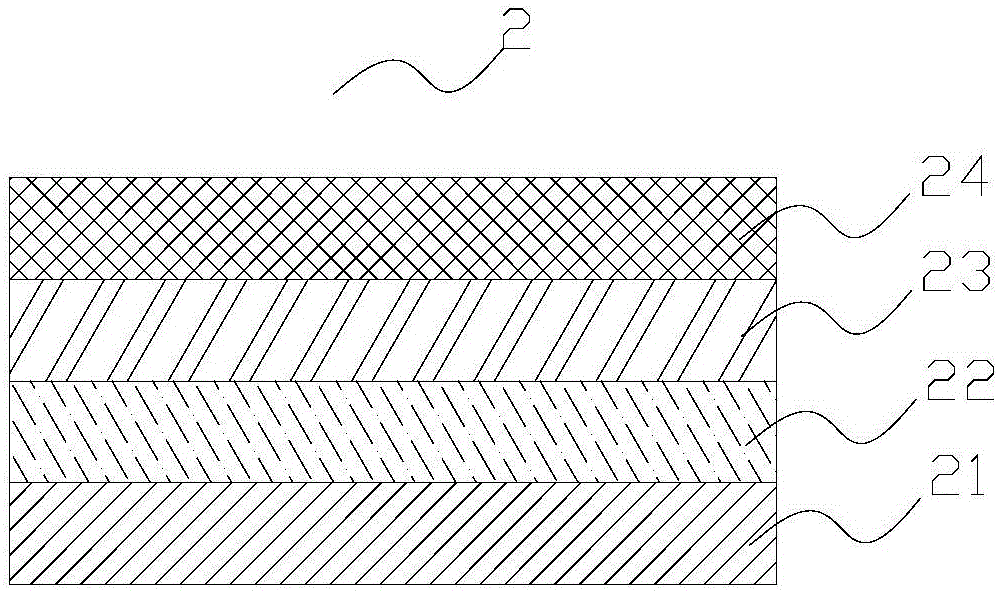

[0018] S02. Provide a first solution in which a hole injection material is dissolved, scrape coat the first solution on the surface of the transparent conductive substrate away from the fixed substrate, perform a first heat treatment, and prepare a hole injection layer;

[0019] S03. Provide a second solution in which the luminescent material is dissolved, scrape coat the second solution on the surface of the hole injection layer away from the transparent conductive substrate, and perform a second heat treatment to prepare an active layer;

[0020] S04. Depositing a cathode material on the surface of the active layer away from the active layer to prepare a cathode layer.

[0021] Speci...

Embodiment 1

[0037] A method for preparing a large-area light-emitting electrochemical cell device, comprising the following steps:

[0038] S11. Provide a fixed substrate with a heating function, on which a 6-inch transparent conductive ITO glass is fixed;

[0039] S12. Provide PEDOT:PSS solution, scrape the PEDOT:PSS solution on the surface of the transparent conductive ITO glass away from the fixed substrate, the distance between the scraper and the conductive ITO glass plate is 0.5mm, and the moving speed of the scraper is 0.5mm cm / s, the temperature of the fixed substrate is 80°C, and the hole injection layer is prepared by heating at 150°C for 15 minutes after scraping;

[0040] S13. Provide [Ir(ppy) 2 (trzpy-)]PF 6 (Ionic iridium metal compound) in acetonitrile solution, scrape-coat the [Ir(ppy) on the surface of the hole injection layer away from the transparent conductive substrate 2 (trzpy-)]PF 6 (Ionic iridium metal compound) in acetonitrile solution, the distance between th...

Embodiment 2

[0043] A method for preparing a large-area light-emitting electrochemical cell device, comprising the following steps:

[0044] S21. Provide a fixed substrate with a heating function, on which a 6-inch transparent conductive ITO glass is fixed;

[0045] S22. Provide PEDOT:PSS solution, scrape the PEDOT:PSS solution on the surface of the transparent conductive ITO glass away from the fixed substrate, the distance between the scraper and the conductive ITO glass plate is 0.5mm, and the moving speed of the scraper is 0.5mm cm / s, the temperature of the fixed substrate is 80°C, and the hole injection layer is prepared by heating at 150°C for 15 minutes after scraping;

[0046] S23. Provide 60mg / ml of [Ir(ppy) 2 (trzpy-)]PF 6 (Ionic iridium metal compound) in acetonitrile solution, scrape-coat the [Ir(ppy) on the surface of the hole injection layer away from the transparent conductive substrate 2 (trzpy-)]PF 6 (Ionic iridium metal compound) in acetonitrile solution, the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com