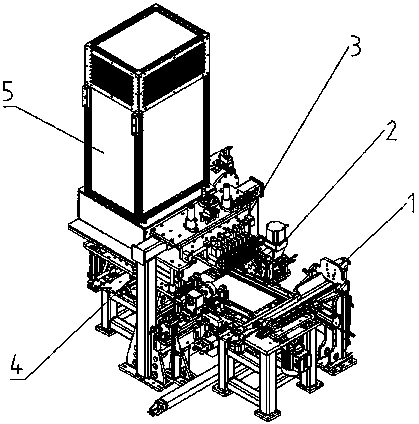

Fully-automatic method for horizontally injecting hot melt adhesive and adhesive-injecting machine thereof

A hot-melt adhesive and fully automatic technology, which is applied in the field of glue injection, can solve the problems of glue breaking, low production efficiency, and difficulty in ensuring the quality of the fixed folding distance of the filter, etc., and achieve the effect of reducing processing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

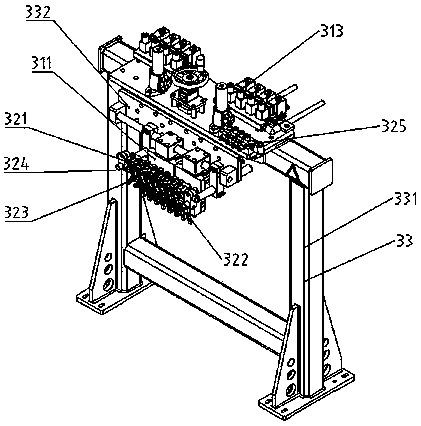

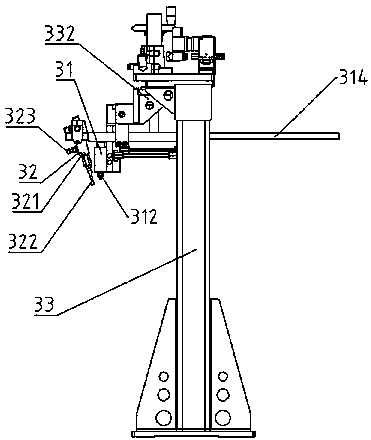

[0029] The specific implementation method of the present invention is described below.

[0030] The automatic hot-melt adhesive horizontal glue injection method of the present invention mainly includes the following steps: placing the product horizontally, using a servo motor to drive the product to rotate, injecting glue on the product in the vertical direction, and using low-temperature compressed air to heat-melt the surface of the product The glue is cooled. After the glue is injected, the product is conveyed horizontally while the product is kept rotating, and the hot melt glue on the surface of the product is cooled again by cold air.

[0031] In the automatic hot melt adhesive horizontal glue injection method of the present invention, a servo motor is used to drive the product to rotate. It is driven by a servo motor to realize the rotation speed and rotation angle, and the parameter editing and parameter preset functions can be performed on the man-machine operation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com