Quality inspection method applied to riveting portion of joint column and plate member

A technology of quality inspection and connecting columns, which is applied in the direction of applying stable torsion to test the strength of materials, measuring devices, instruments, etc., can solve the problems of design quality inspection methods, and achieve the effect of simple and easy detection and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

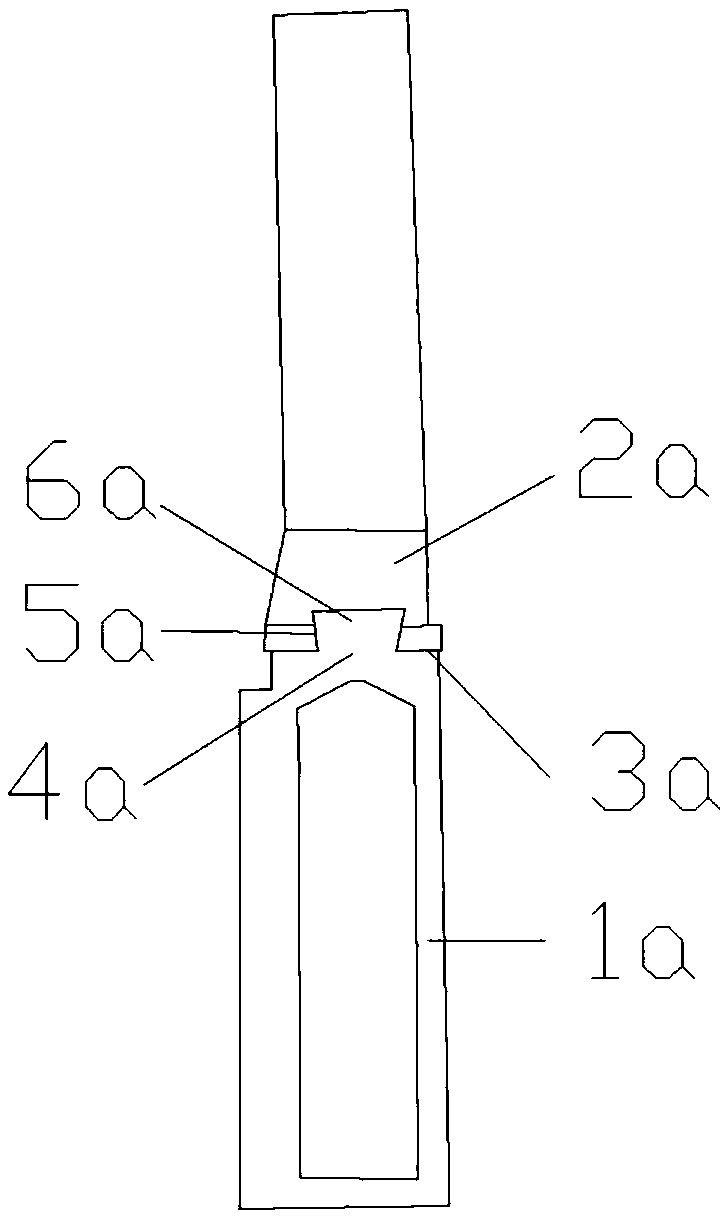

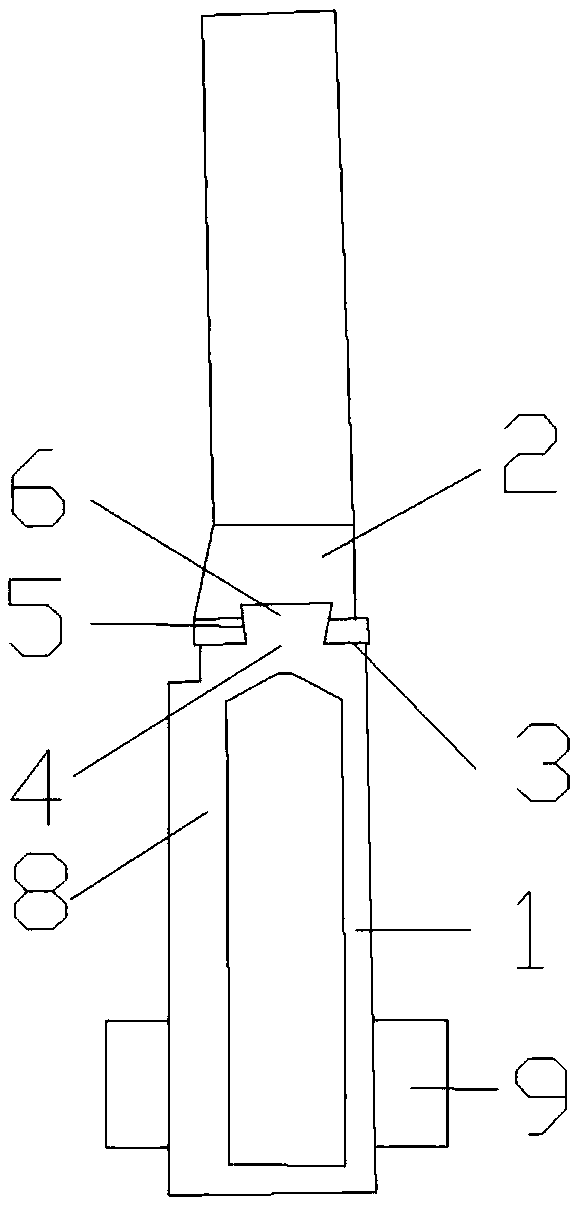

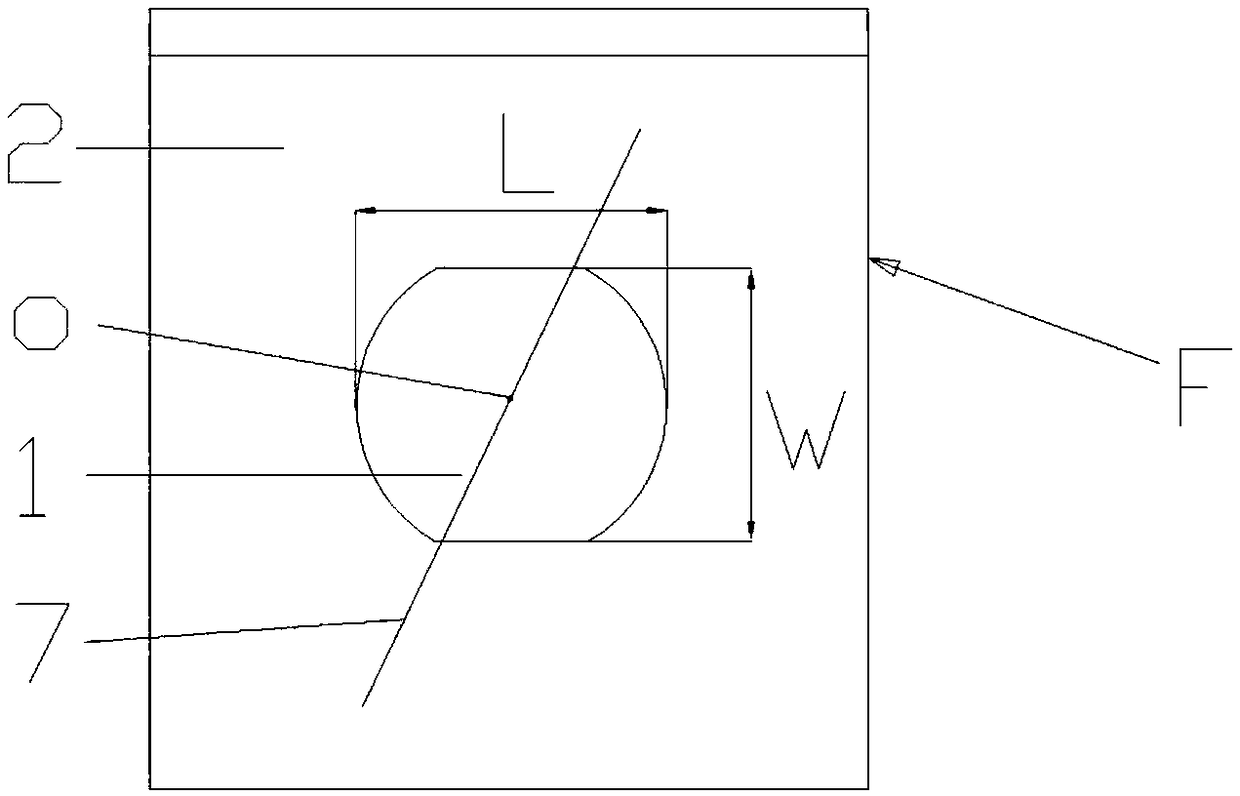

[0026] A quality inspection method applied to the riveted part of the connecting column and the plate, the riveting end 4 of the connecting column 1 is thinned along the wall thickness direction to form an annular stepped surface 3 against the lower surface of the plate 2, The riveted end 4 of the connecting column 1 is installed in the mounting hole 5 of the panel 2, and the top of the riveted end 4 of the connecting column 1 is riveted and extended to form a nail head 6 to connect the connecting column 1 and the panel 2 together, In this embodiment, the connection column 1 is the current copper column of the electric meter, the plate part 2 is a copper sheet, and the initial length L and width W of the top of the riveted end 4 of the current copper column are 4.4mm and 5mm respectively, and the method includes the following steps :

[0027] (1) Detection of the extension size of the riveting part: measure the length L and width W of the extended top of the current copper col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com