A long cycle refueling loading method for super large pressurized water reactor core

A pressurized water reactor, ultra-large technology, applied in the field of nuclear power, to achieve the effect of improving neutron economy, reducing cost, improving safety and fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

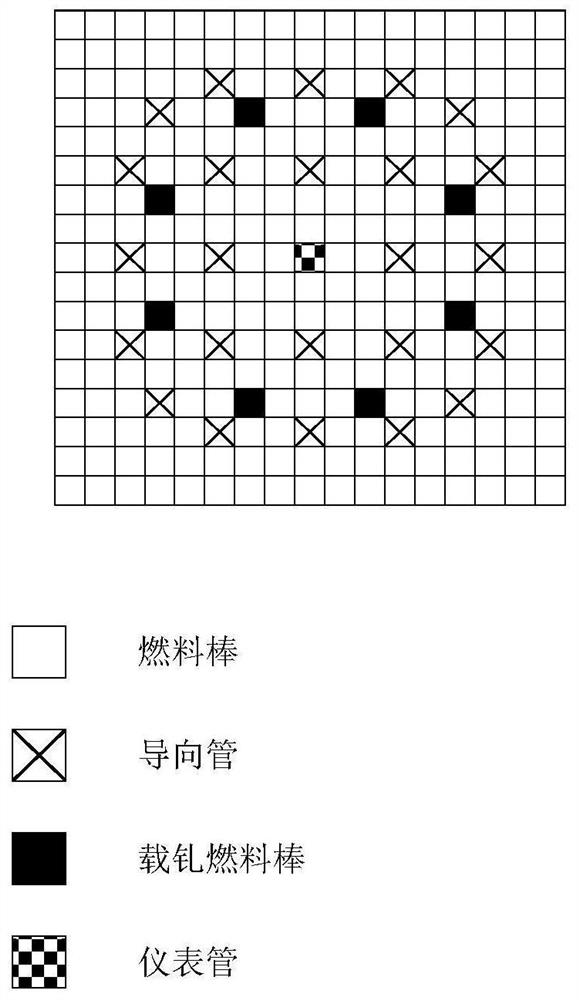

[0037] Such as Figure 1-Figure 5 Shown, the present invention provides a kind of ultra-large pressurized water reactor core long cycle refueling loading method, comprises the following steps:

[0038] 1) The high-leakage loading mode is adopted for the first cycle core, and a total of 221 sets of fuel assemblies are loaded into the core. The fuel assemblies adopt 3 to 6 different enrichment degrees, and the U-235 enrichment degrees of the fuel assemblies are distributed between 1.6% and 4.0%, wherein the components with the highest enrichment degree are arranged at the outermost circle of the core, and the fuel assemblies with lower enrichment degrees are arranged in a cross checkerboard pattern inside the core. The height of the active section of the fuel rod is 14 feet, and the fuel assembly is partitioned in the axial direction according to the needs, that is, no burnable poison is installed at the end, and fuel with a lower enrichment degree is used as the case may be, so...

Embodiment 2

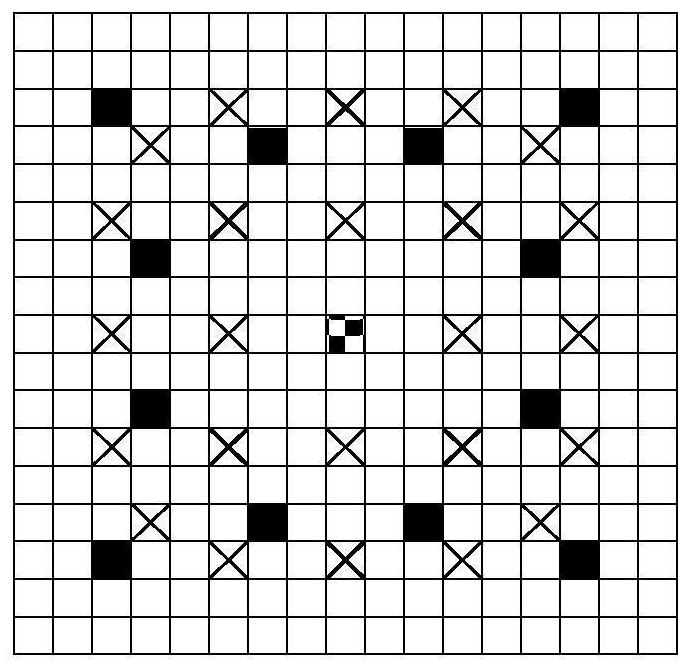

[0046] This example illustrates the total number of new components in the transition cycle and the balance cycle.

[0047] The invention relates to a super-large pressurized water reactor core long-cycle refueling and loading method. The total number of new components in the transition cycle and the balance cycle is between 80 groups and 116 groups.

[0048] The length of the core maneuvering cycle can be adjusted by adjusting the number of new components with a certain number of new components and only adjusting the ratio of the new components of the two enrichments. For example, the total number of new components is 100, and the components of the two enrichments are 80 and 20 respectively; The length of the core maneuvering cycle is adjusted by adding or subtracting the total number of new components in the core, for example, increasing the number of new components from 80 to 116, so that the core can achieve a wider range of maneuvering operations and stronger maneuverabilit...

Embodiment 3

[0050] Lay out the fuel assemblies using a 17×17 grid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com