Heat sink

A radiator and heat sink technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Novel design, not easy to fall off, saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

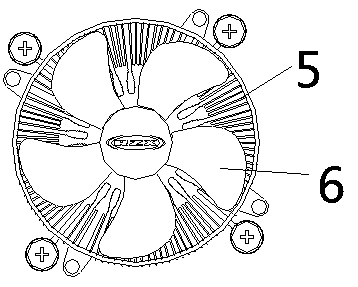

[0031] figure 1 is the whole of the radiator in this embodiment 1 Figure 1 , a radiator, comprising some heat sinks 5, fans 6 and some connecting mechanisms, each heat sink 5 is distributed radially in a circle, the fan 6 is arranged at the center of the heat sink 5, and each connection mechanism is evenly arranged on each heat sink 5 on.

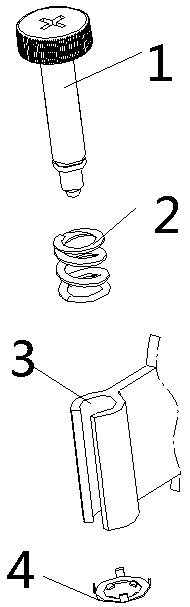

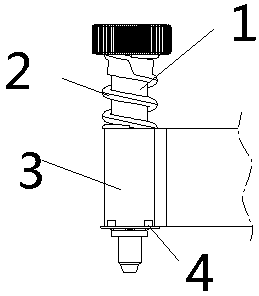

[0032] figure 2 , 3 They are the exploded view and structural schematic diagram of the connection mechanism in the radiator respectively, wherein the connection mechanism includes screw 1, spring 2, screw through hole 3 and snap ring 4; screw 1 is penetrated in screw through hole 3, and spring 2 is sleeved On the screw 1, and the spring 2 is located between the screw through hole 3 and the nut 11 of the screw 1; the snap ring 4 is snapped on the screw 1, and the snap ring 4 abuts on the screw through hole 3 and is opposite to the spring 2 the other side of the

[0033] Figure 4 It is an enlarged view of the screws and springs in th...

Embodiment 2

[0040] Different from Example 1, as Figure 7 , each cooling fin 5 is radially distributed horizontally and vertically. The radiator provided by this embodiment is easy to install and use, and has a fast cooling effect, and is suitable for large-scale application of electronic devices and equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com