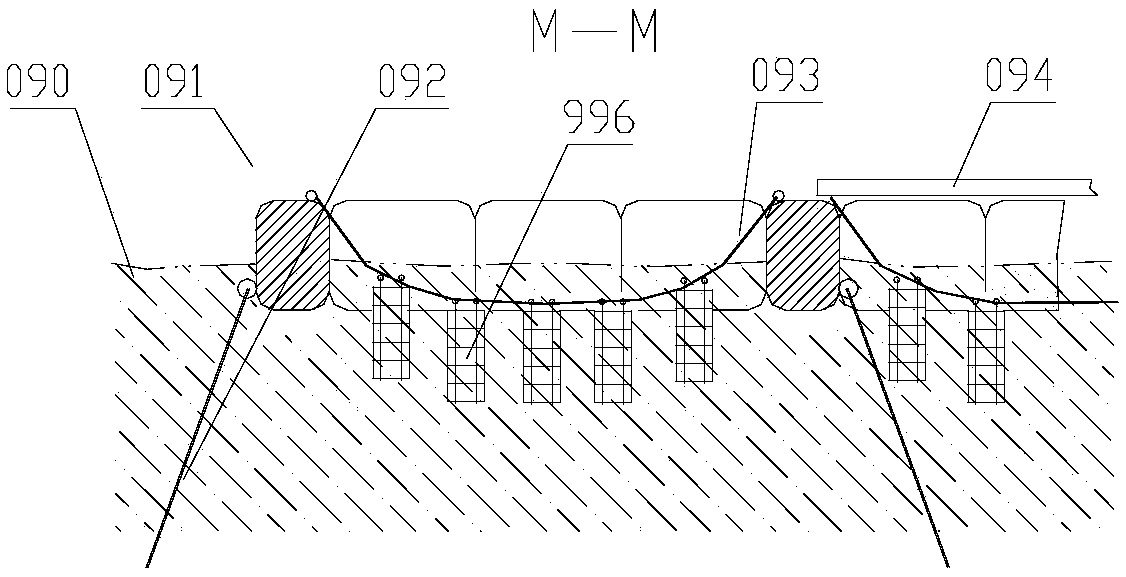

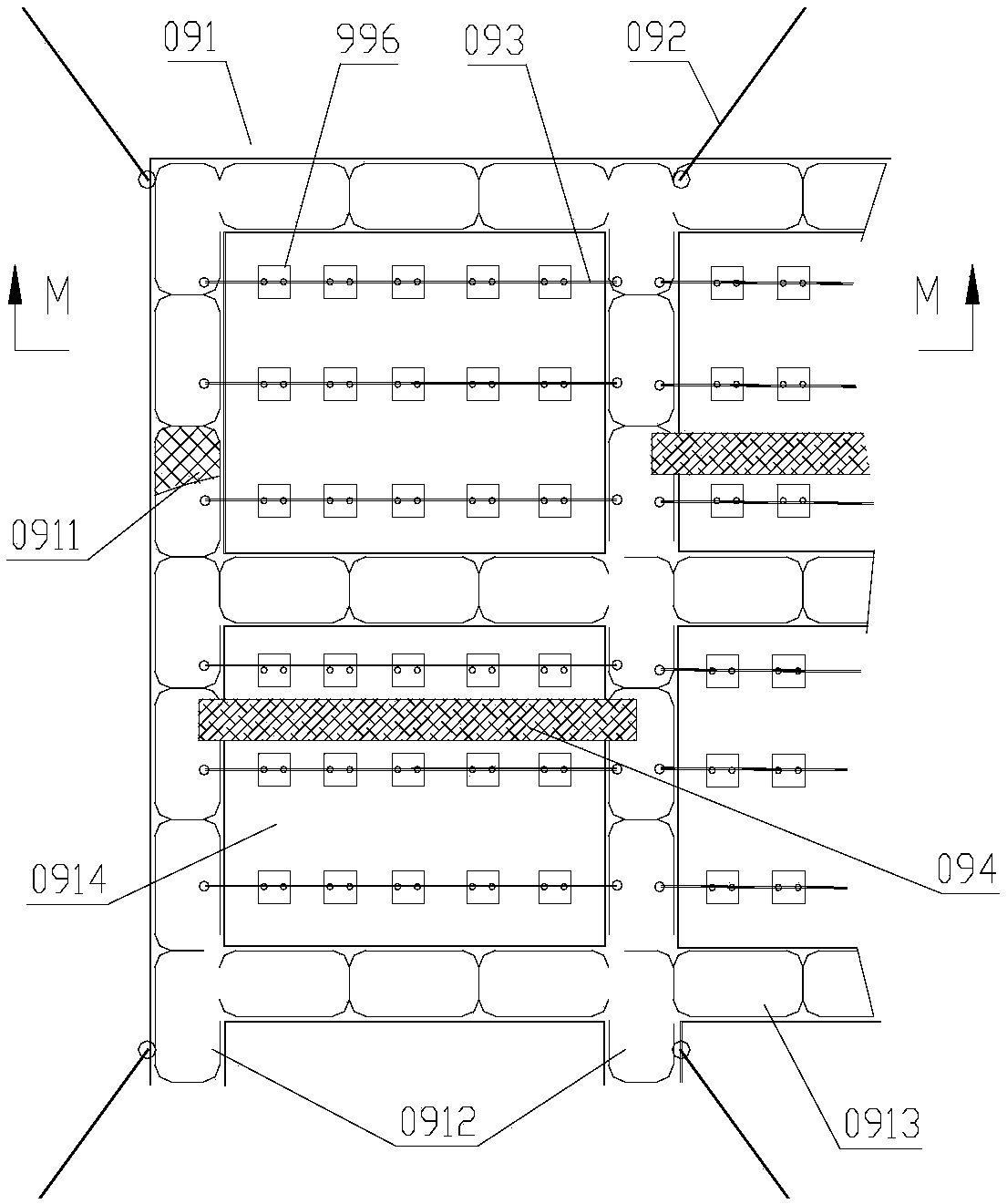

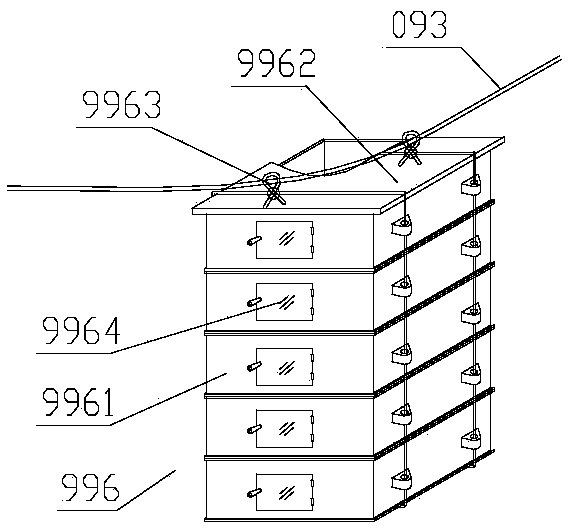

[0004] like image 3 Shown, a kind of breeding box group 996 is a kind of breeding box group of existing sea abalone, and described breeding box group is stacked and bundled into a group by several (usually 5) breeding box 9961, and each breeding box group contains The weight of mature abalone is about 20 kg inside. The breeding box is rectangular or square with an opening on the top. Stack up, fasten the uppermost box mouth with cover plate 9962, then string together and bind together with

rope 9963 through the

rope holes on the side of several breeding boxes to form a group; one side of each breeding box 9961 is provided with a window door 9964, the window and door are equipped with hinges and bolts that can be opened and locked. This window and door are used to feed abalone daily and observe the growth of abalone; each group of breeding boxes is tied to the hanging

rope on the fish raft by rope 9963 093; some users cover a group of breeding boxes with a net bag, and then tie the net bag to the above-mentioned hanging rope and hang it in the sea water, so that each breeding box in the group of breeding boxes covered with net bags is fixed. Will be stronger, however, the feeding process is more troublesome and time-consuming to open

[0005] The feed for abalones in the existing cultured abalones is

algae, and now

kelp is used, and the

kelp is

cut into fine pieces or shredded. The method is: the feed worker first uses a container to take out the feed from the large container with the feed on the fish raft or load the feed from the boat parked beside the fish raft (the boat is a traffic ferry between the fish raft and the

shore, used for Transport personnel and materials), carry the container filled with feed to the side of the breeding pond, stand on the skeleton of the fish steak or stand on the board of the breeding pond, then lift the hanging rope from the breeding pond to untie the breeding box group, and put the breeding box Lift the group up and put it on the

buoy at the

pool or on the board, open the windows and

doors on the breeding box, grab a handful of

kelp fragments from the container and throw them into the windows and

doors, then lock the windows and

doors, and put the breeding box The group is tied to a lanyard and put back into the sea; the amount of feeding into each breeding box is about the same each time, and the amount of feeding is completely measured by the feel of each time. Because the soaked kelp fragments are very sticky and slippery, they are easy to slide. The feed that is caught in the hands is easy to slip away, so it is inevitable that there will be errors in the measurement of the feel of the feed every time. It does not matter if there is a small error, but if there are too many errors or the workers are careless and feed more, the abalones cannot finish eating, and the feed rot will affect the growth of the abalones. , found that the rotting material must be cleaned out of the box; once every two or three days, it depends on the size and quantity of abalone, and it is carried out repeatedly like this; because there are a large number of breeding ponds built on the fish rafts of large farms, there are dozens or even hundreds of abalones. Therefore, the whole farm has tens of thousands of breeding boxes or thousands of bundles of breeding box groups, and the workers have to lift the breeding box groups from the sea every time and place them on the edge of the fish raft or on the board. , you have to bow your body or

squat to operate, untie the rope, open the net bag, open the window door 9964, grab the material, feed the material, close the door, lock the door, put the net bag on it, tie the rope, and release it into the sea. Dead abalones or a large amount of rotten feed should be taken out from this window. When serious problems are found in the box, the rope 9963 must be opened to clean the abalones in the box, and then tied up and lowered into the sea. This kind of work requires heavy work for the workers,

slow speed and low efficiency. In addition, from the start of breeding abalone fry to mature abalone that can be marketed, several times of boxing work must be carried out in the middle. Finally, it needs to be divided into about 50 boxes per box, and when it is bigger, it needs to be divided into about 20 to 30 boxes per box. Generally, the rope must be untied for this boxing work. The rope comes from the rope hole on the side of the breeding box. If the abalones pass through the middle, untie the rope, remove the breeding box, and carefully separate the abalones according to their size. After the abalones are divided into boxes, they are stacked on the breeding box and tied with ropes. This work process usually requires several workers to cooperate in a group, which is very time-consuming. , the speed is slow and the efficiency is low; especially when operating at sea, you need to bend over and bow your head to operate, which is very hard. Even when the sea is calm, there are

waves. Usually there are wind and

waves in the work, and it is common for feeding workers to seasick and vomit; It can be seen that the existing technical means of abalone farming at sea are generally backward; therefore, the problem arises, how to extract the breeding box from the sea conveniently, how to open and close the window quickly, such as How to quickly and accurately measure the feed and quickly put the feed, how to quickly divide the boxes, these series of problems can improve the breeding efficiency, reduce the labor intensity of the feeding workers, and realize the automatic or semi-automatic breeding production; however, so far these problems There is still no solution, and the feeding is still completely manual operation with a lot of labor, and the workers

squat above the breeding pond to feed; Reducing the labor intensity of breeding workers, improving work efficiency, reducing labor force, and realizing automated, semi-automated or mechanized farming production is a topic with great market prospects.

Login to View More

Login to View More  Login to View More

Login to View More