Injection device for automatic salted fish processing device

A technology of automatic processing and injection device, applied in the field of food processing, can solve problems such as destroying the integrity of fish meat, and achieve the effects of avoiding damage, saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

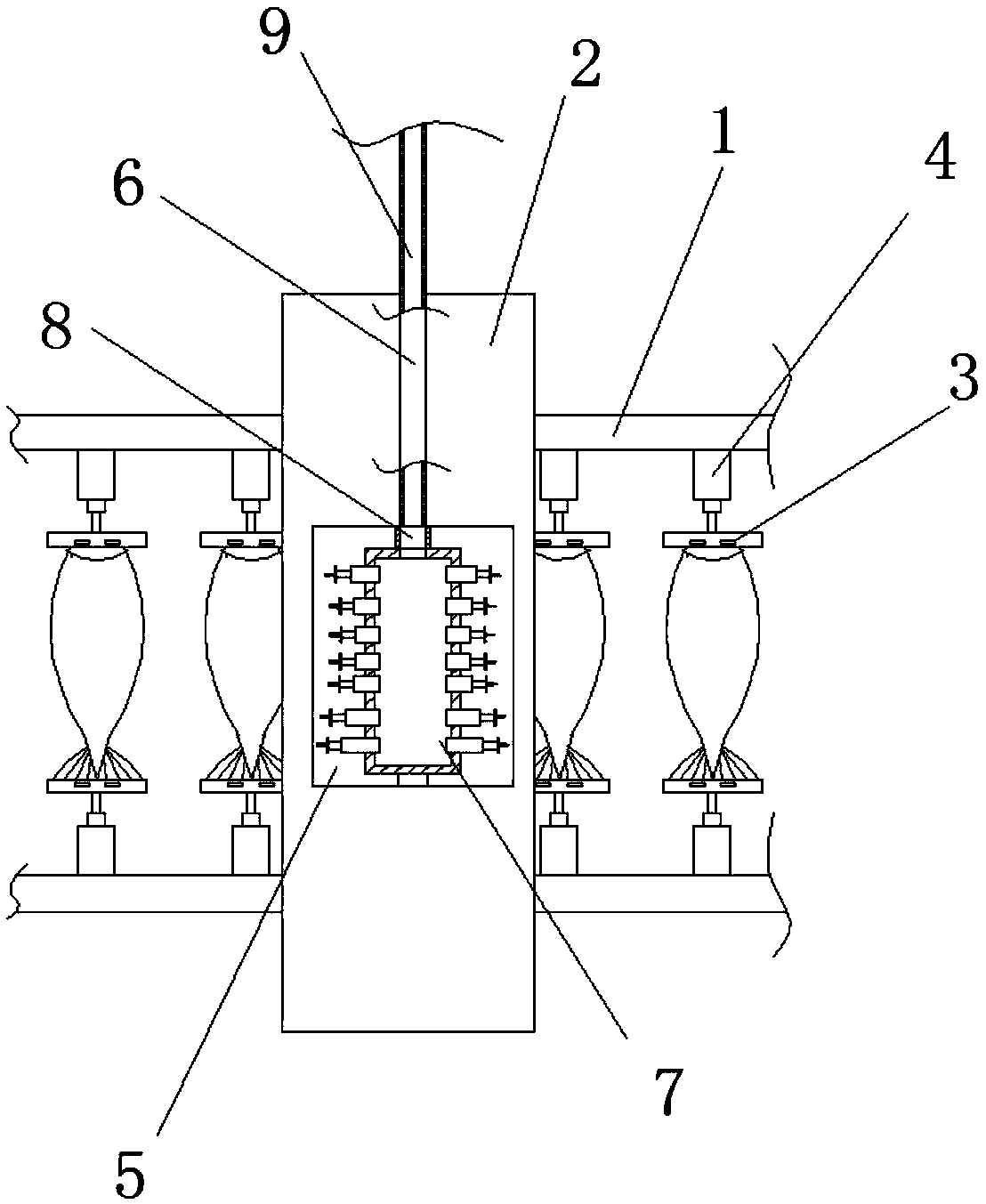

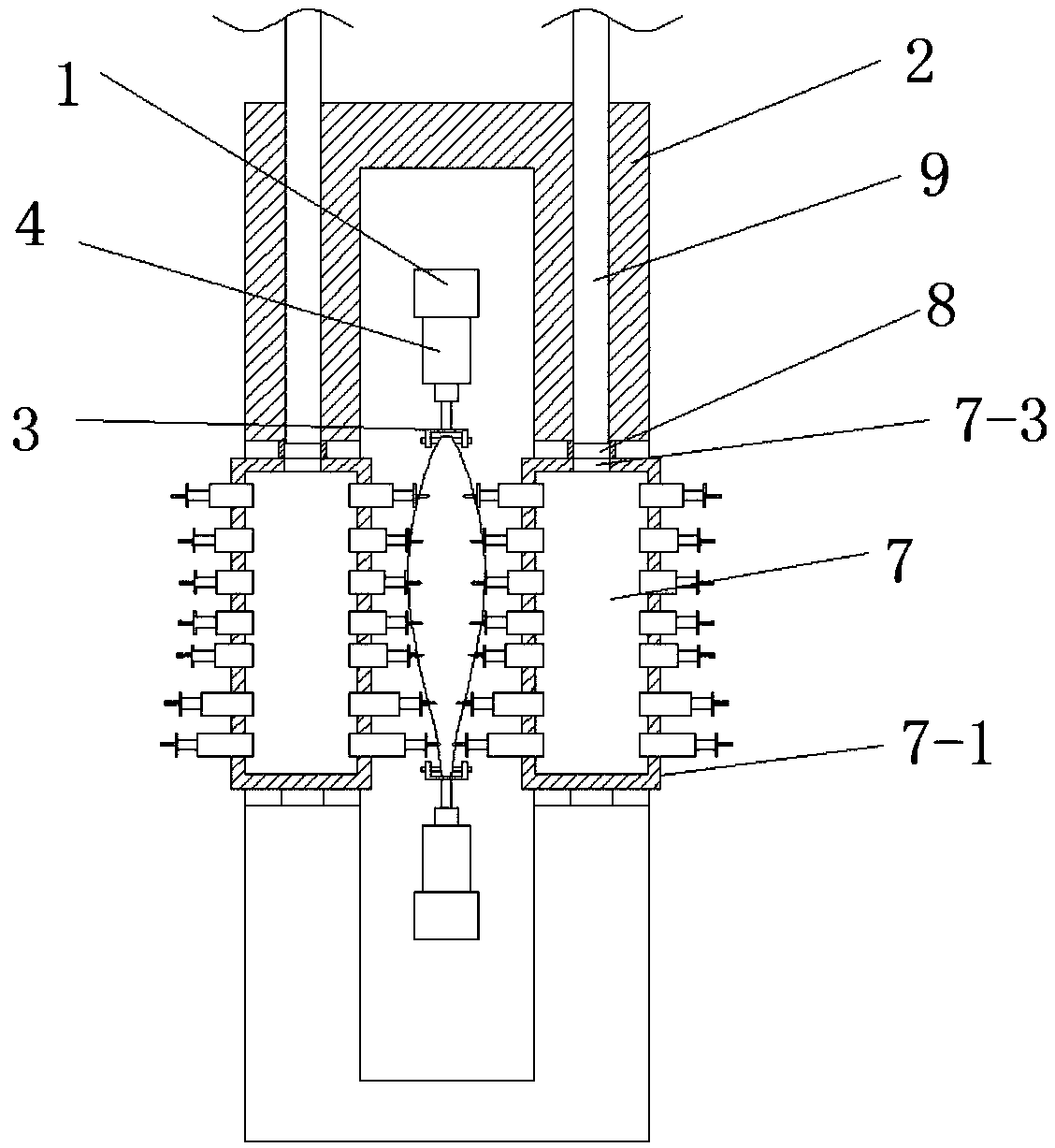

[0027] Such as Figure 1 to Figure 5 As shown, a salted fish automatic processing device disclosed in this embodiment includes a transmission device 1, a fixed frame 2, a fixed clip 3, a cylinder 4, an injection device 7, a hollow rotating shaft 8 and an infusion tube 9; two transmission devices 1 are parallel Set in the fixed frame 2, multiple sets of fixed clips 3 are symmetrically arranged on two parallel transmission devices 1 through the cylinder 4, the two side walls of the fixed frame 2 are symmetrically opened with a rectangular groove 5, and the upper end of the rectangular groove 5 is opened with a through cavity 6, The upper and lower ends of the injection device 7 are respectively arranged in the rectangular groove 5 through the hollow rotating shaft 8 and the rotating shaft. One end of the infusion tube 9 is connected with the high-pressure water pump, and the other end is arranged in the hollow rotating shaft 8 through the cavity 6;

[0028] Such as figure 1 wit...

specific Embodiment approach 2

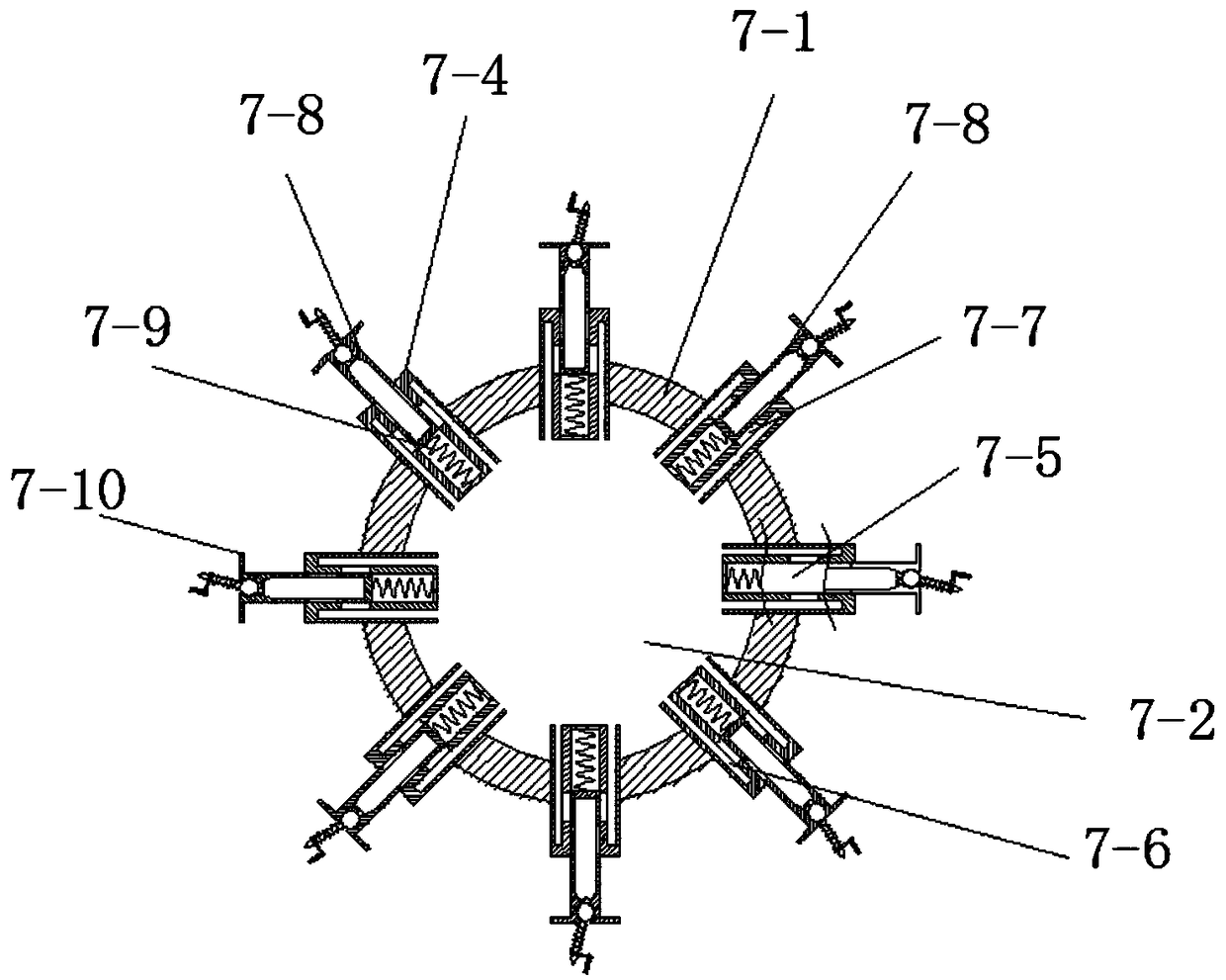

[0034] combine Image 6 with 7 As shown, this embodiment is based on the first embodiment, the difference is that the elastic member 7-8-10 includes a connecting piece 7-8-11, a pressing rod 7-8-12, and a pressing roller 7-8 -13, the second pressure spring 7-8-14, the fixed rod 7-8-15 and the limit protrusion 7-8-16; one end of the connecting piece 7-8-11 and the limit ring 7-8-8 The side walls are connected, and one end of the symmetrically arranged pressure rod 7-8-12 is connected through the pressure roller 7-8-13, and the other end passes through the second pressure spring 7-8-14 and the connecting piece 7-8-11 in sequence, And be connected by fixed rod 7-8-15, one end of the second pressure spring 7-8-14 links to each other with connecting piece 7-8-11, and the other end is connected with the limit protrusion on the side wall of pressure rod 7-8-12 From 7-8-16 connected;

[0035] The changing process of the power of elastic member 7-8-10, the pushing force of beginning...

specific Embodiment approach 3

[0036] combine Figure 4 with 5 , this embodiment is based on the first embodiment, the difference is that the elastic member 7-8-10 includes a connecting piece 7-8-11, a pressing rod 7-8-12, and a pressing roller 7-8-13 , the second pressure spring 7-8-14, the fixed rod 7-8-15 and the limit protrusion 7-8-16; one end of the connecting piece 7-8-11 and the side wall of the limit ring 7-8-8 Connected, one end of the symmetrically arranged pressure rod 7-8-12 is connected through the pressure roller 7-8-13, and the other end passes through the second pressure spring 7-8-14 and the connecting piece 7-8-11 in turn, and passes through The fixed rod 7-8-15 is connected, and one end of the second pressure spring 7-8-14 is connected with the connecting piece 7-8-11, and the other end is connected with the limit protrusion 7 on the side wall of the pressure rod 7-8-12 -8-16 connected.

[0037] Further, the distance from the highest point of the pressure roller 7-8-13 to the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com