A cleaning device for cleaning the inner wall of a vertical oil pipe

A cleaning device and oil pipe technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of oil pipes that cannot be cleaned vertically, recycling of cleaners, and descaling of oil pipes that cannot be vertical, etc. problem, to achieve the effect of safe and reliable delivery and recovery, easy promotion and use, and good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

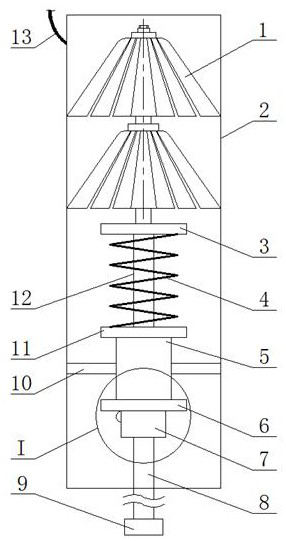

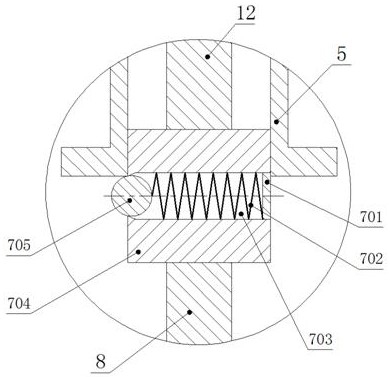

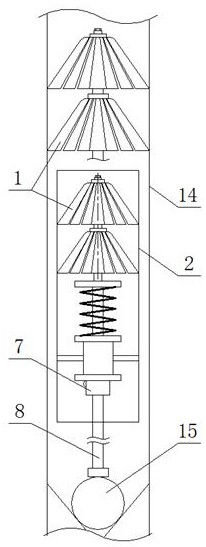

[0017] Referring to each figure, a cleaning device for cleaning the inner wall of a vertical oil pipe includes a cavitation jet 1, and also includes an ejection sleeve 2 for ejecting the cavitation jet 1. The cavitation jet 1 is located in the ejection sleeve 2, The ejection sleeve 2 includes a snap-in guide sleeve 5 and an ejection switch 7 that can be triggered. The ejection switch 7 is installed on the bottom of the snap-in guide sleeve 5. The top of the ejection switch 7 is connected to the connecting rod 12. The connecting shaft of the cavitation jet 1 is connected, the connecting rod 12 at the bottom end of the blocking plate 3 is covered with a compressed ejection spring 4, and the bottom end of the ejection switch 7 is connected with the ejector rod 8; the ejection switch 7 includes a cylinder 704 and a steel ball 705 And the spring 702, the steel ball 705 is located in the circular cavity 703 of the cylinder 704, the steel ball 705 is provided with a spring 702 at one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com