Full-automatic quick tightening mechanism suitable for bolt and nut

A bolt and nut, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long operation time, lack of automatic tightening tools, poor tightening effect, etc., to achieve broad market prospects and save manpower As well as the operating time, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

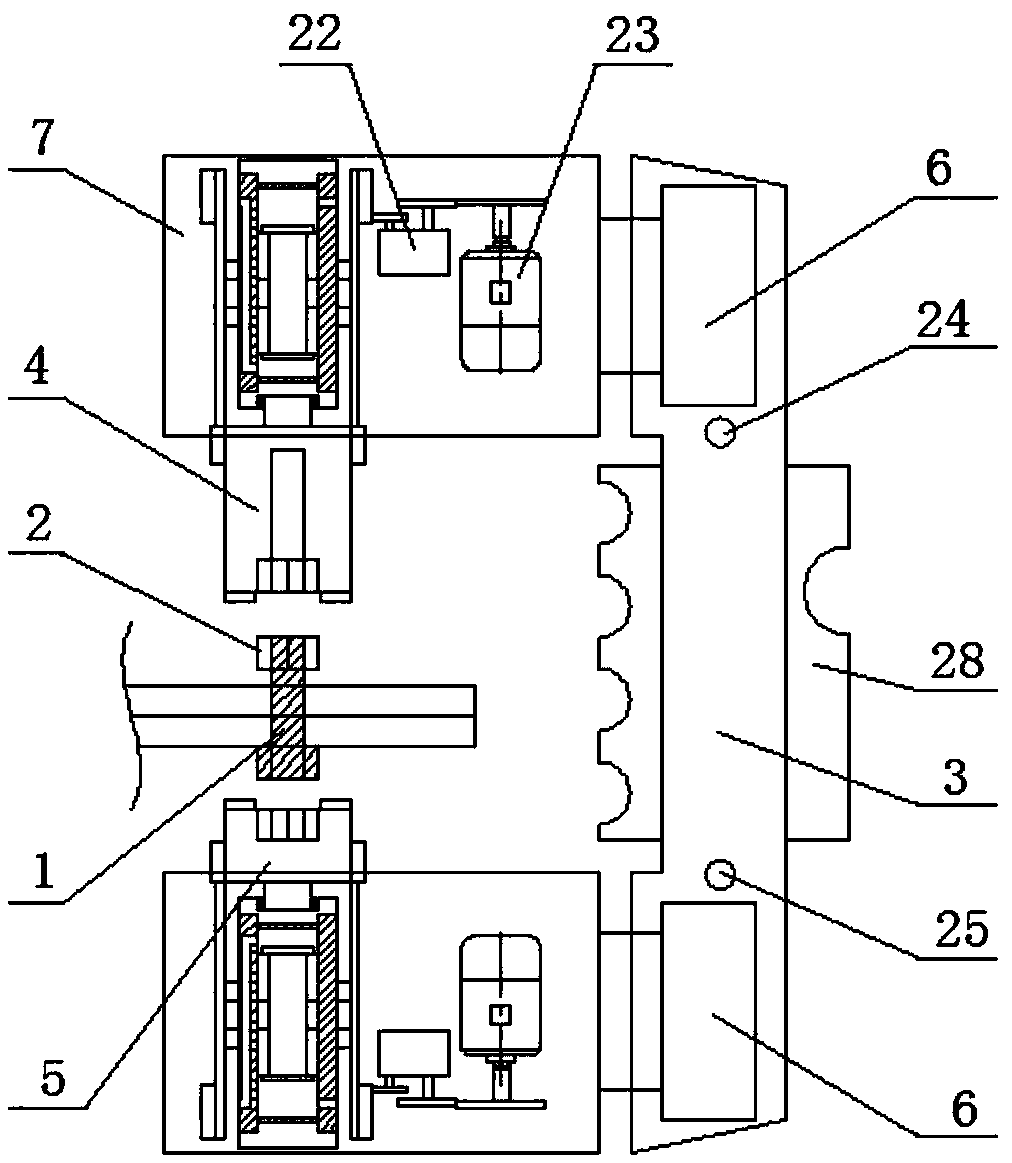

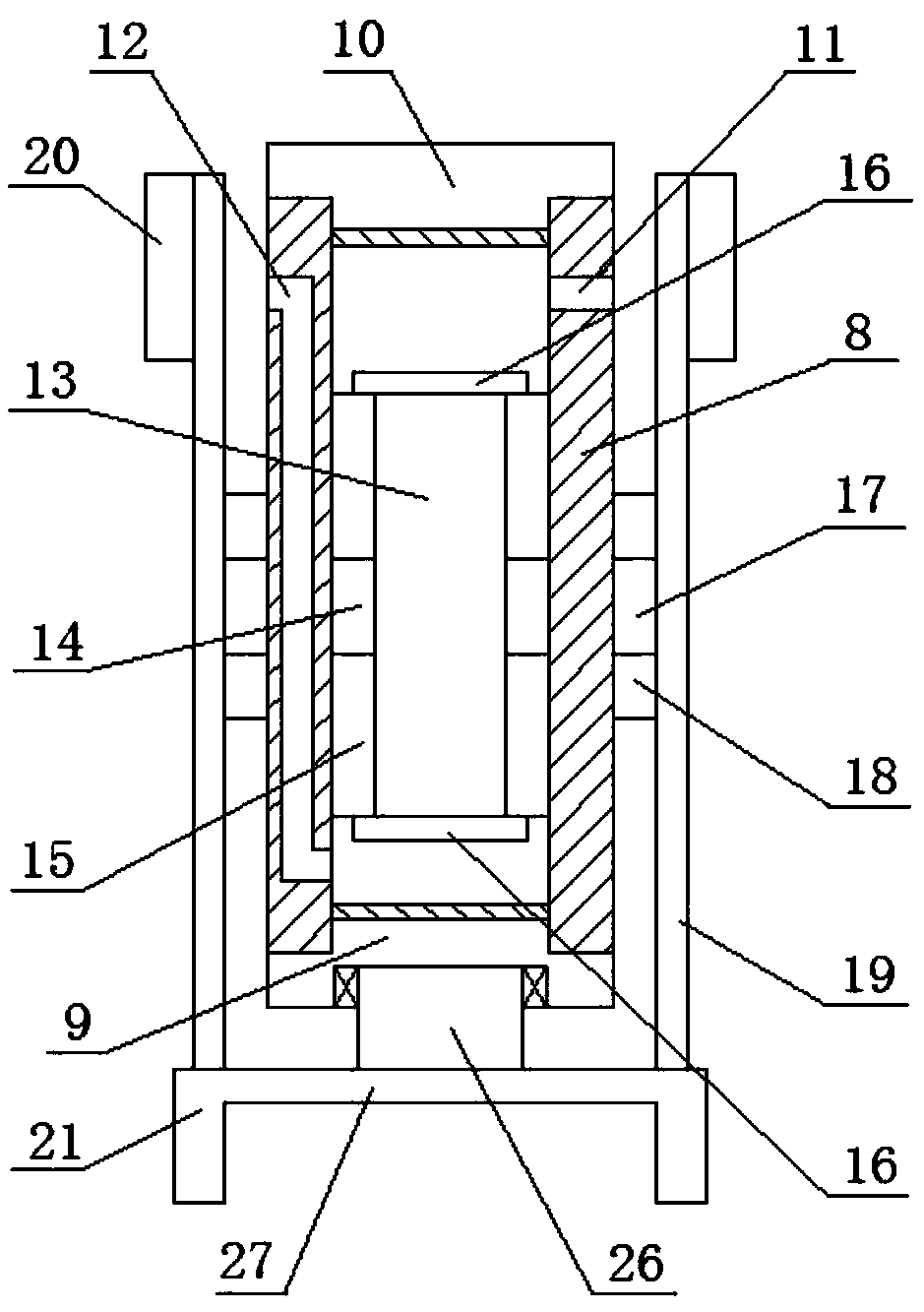

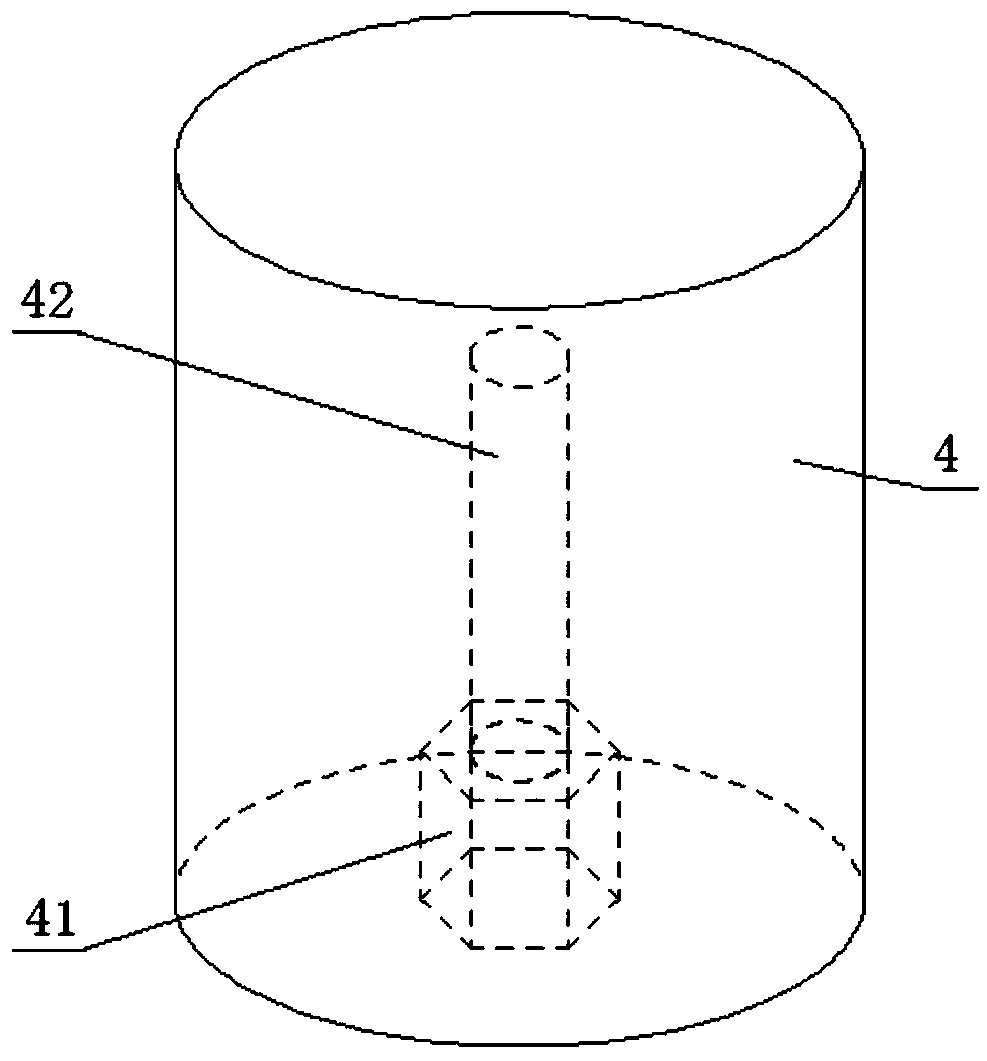

[0029]This embodiment provides a fully automatic fast tightening mechanism suitable for bolts and nuts, used for tightening the matched bolts 1 and nuts 2, the structure is shown in the figure, including a support handle 3, nut clips 4 and bolt clips Connector 5, the upper and lower ends of the support handle 3 are symmetrically provided with a rotating lifting assembly, and the rotating lifting assembly is connected with the supporting handle 3 through a horizontal cylinder 6; The support oil cylinder 8, the support oil cylinder 8 has a cylindrical structure, and its inner end and outer end are respectively provided with an inner end cover 9 and an outer end cover 10, and the side walls of the support oil cylinder 8 are respectively provided with oil inlets 11 and the oil outlet 12, the supporting column 8 is provided with a supporting column 13, the supporting column 13 is a vertically arranged cylindrical structure, and the outer middle part of the supporting column 13 is pr...

Embodiment 2

[0036] This embodiment provides a fully automatic fast tightening mechanism suitable for bolts and nuts, used for tightening the matched bolts 1 and nuts 2, the structure is shown in the figure, including a support handle 3, nut clips 4 and bolt clips Connector 5, the upper and lower ends of the support handle 3 are symmetrically provided with a rotating lifting assembly, and the rotating lifting assembly is connected with the supporting handle 3 through a horizontal cylinder 6; The support oil cylinder 8, the support oil cylinder 8 has a cylindrical structure, and its inner end and outer end are respectively provided with an inner end cover 9 and an outer end cover 10, and the side walls of the support oil cylinder 8 are respectively provided with oil inlets 11 and the oil outlet 12, the supporting column 8 is provided with a supporting column 13, the supporting column 13 is a vertically arranged cylindrical structure, and the outer middle part of the supporting column 13 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com