Centering auxiliary clamp for 3R fixture to clamp blank materials

An auxiliary fixture and clamping technology, applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems that the reference edge of the electrode cannot be processed in place, the blank cannot be clamped accurately, and the electrode is unqualified, etc., to achieve shortening Clamping time, improving the workpiece qualification rate, and improving the effect of clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

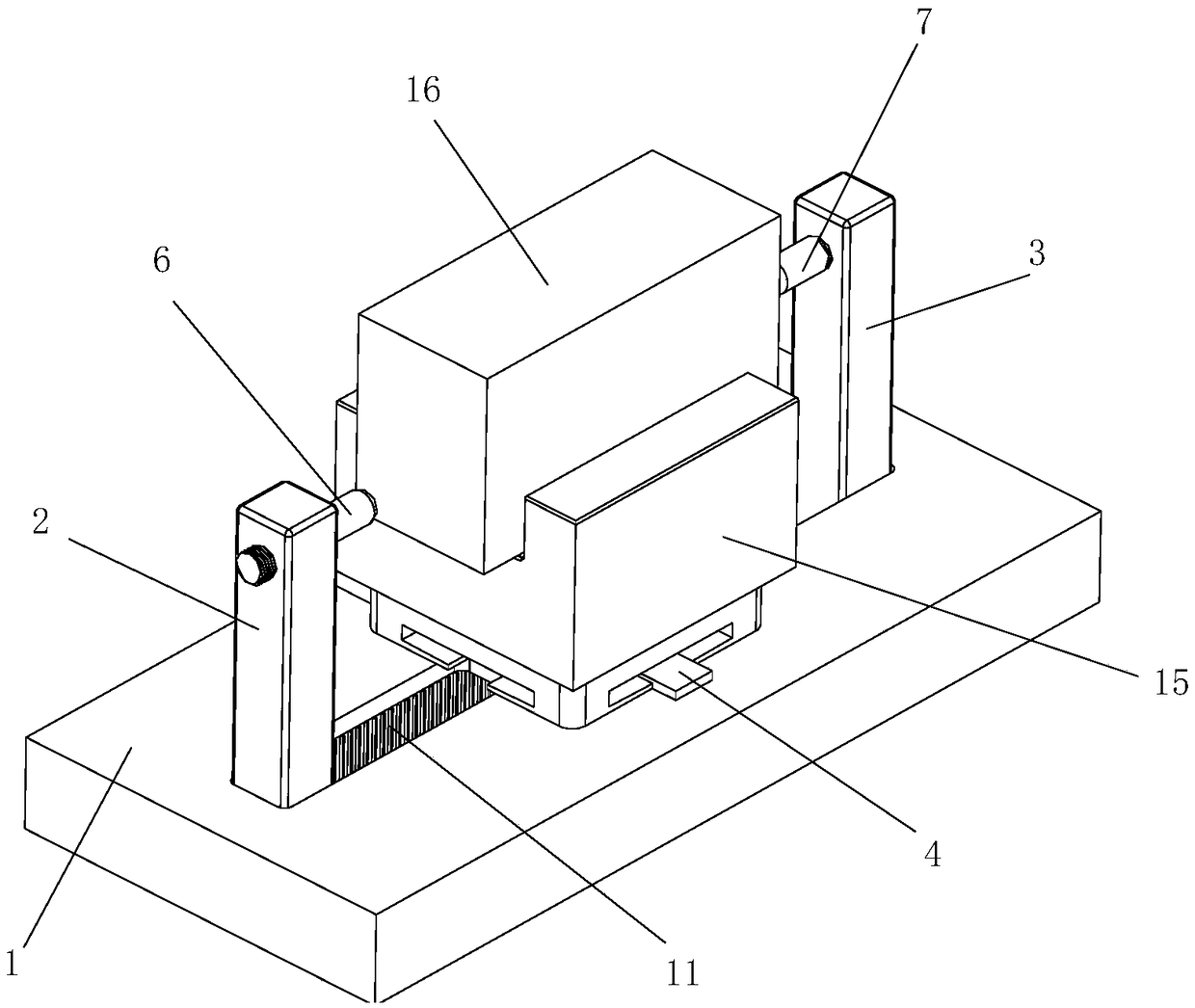

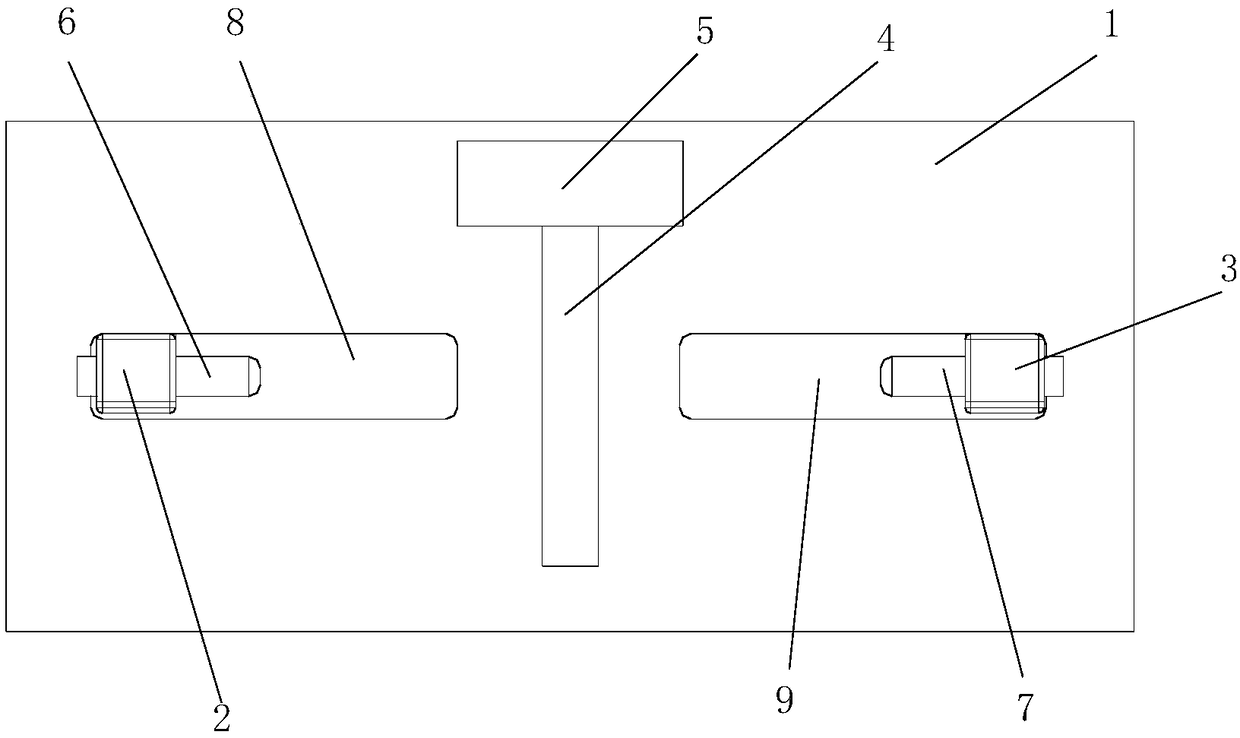

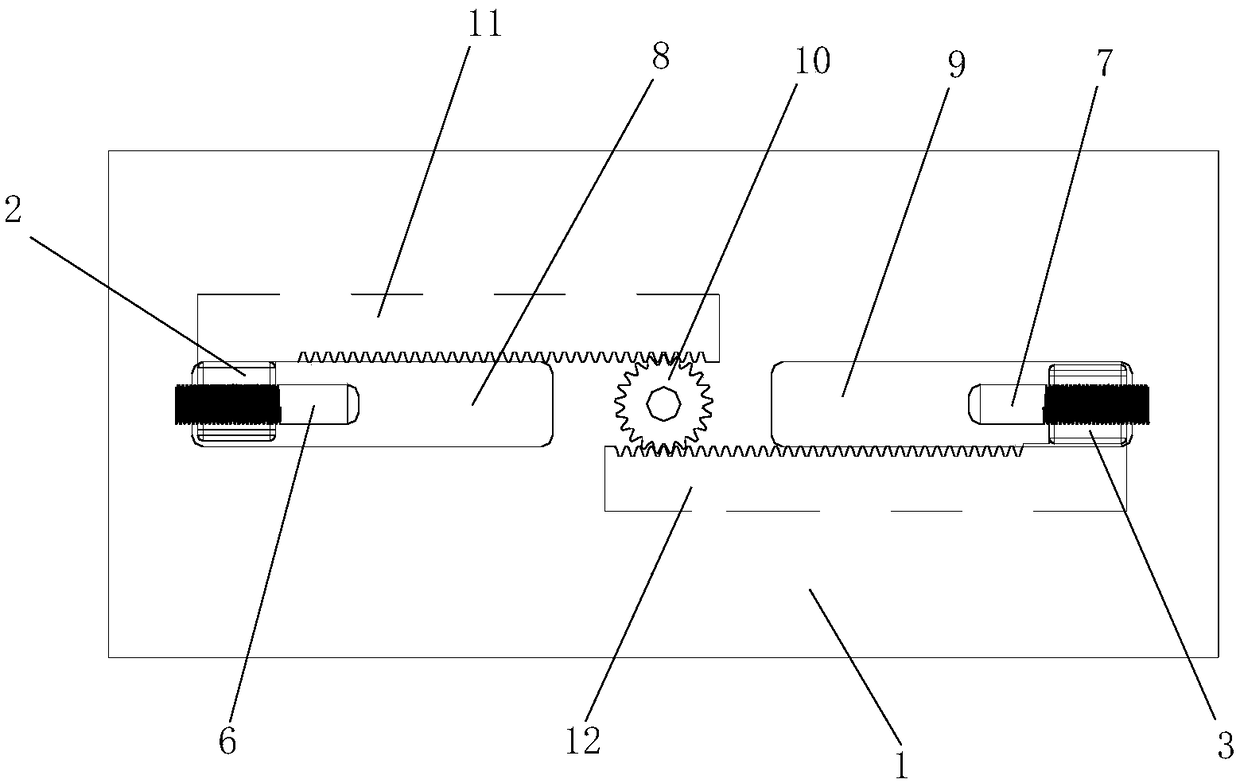

[0015] Such as Figure 1-Figure 5 as shown, figure 1 It is a structural schematic diagram of a centering auxiliary fixture for a 3R fixture for clamping blanks proposed by the present invention; figure 2 It is a top view of a centering auxiliary fixture for a 3R fixture for clamping blanks proposed by the present invention; image 3 It is a structural schematic diagram of the driver in the centering auxiliary fixture for a 3R fixture for clamping blanks proposed by the present invention; Figure 4 It is a schematic diagram of the assembly of the first rack and the first slide bar in the centering auxiliary fixture for a 3R fixture for clamping blanks proposed by the present invention; Figure 5 It is a schematic diagram of the assembly of the second rack and the second slide bar in the centering auxiliary fixture for a 3R fixture for clamping blanks proposed by the present invention.

[0016] refer to Figure 1-Figure 5 , the present invention proposes a centering auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com