Hydraulic manned device for spherical tank internal inspection

A spherical tank and hydraulic technology, which is applied in the field of industrial special inspection equipment, can solve the problems of cumbersome installation, limited swing range of the slewing support arm, inconvenient disassembly and assembly, etc., and achieve the effect of improving safety detection, improving work efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

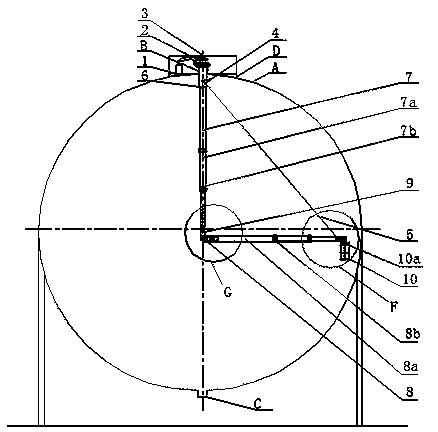

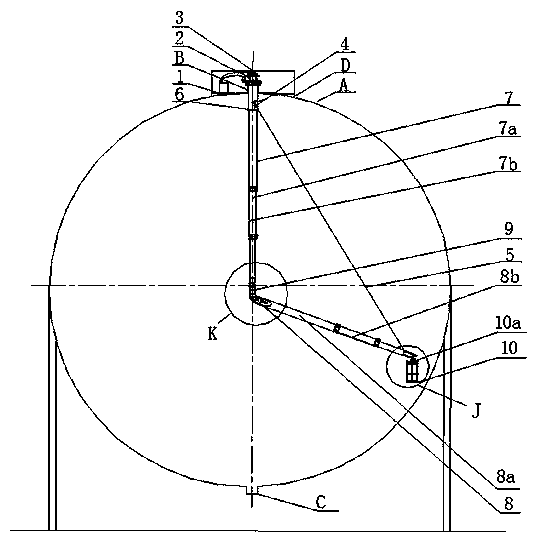

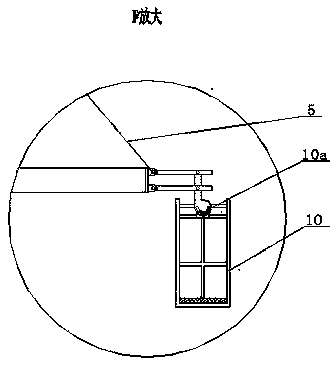

[0024] figure 1 , 4 , 5 shows the vertical structure of the horizontal hydraulic telescopic boom and the longitudinal hydraulic telescopic boom. In the figure, this kind of hydraulic manned device for regular inspection of the spherical tank includes a longitudinal hydraulic telescopic arm 7, a transverse hydraulic telescopic arm 8, a connecting arm 9, a manned basket 10, a hydraulic station 1, a longitudinal rotary arm set in the spherical tank A Mechanism 2 and hydraulic winch 3. The first hydraulic cylinder 7a and the first sprocket chain 7b are installed in the arm of the longitudinal hydraulic telescopic arm 7, so as to realize the synchronous expansion and contraction of the three longitudinal hydraulic arms. The upper end of the longitudinal hydraulic telescopic arm 7 is connected with the upper connecting arm 6, the lower end is connected with the connecting arm 9 through the first hinge 9a, and the connecting arm 9 is connected with the horizontal hydraulic telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com