Biomass fuel combustion furnace

A biomass fuel and combustion furnace technology, which is used in the combustion of solid fuel, controlled combustion, combustion equipment, etc., can solve the problems of clogging the bottom of the furnace, waste of energy, accumulation of a large number of dust particles, etc., to improve combustion efficiency and overcome easy blockage. , the effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

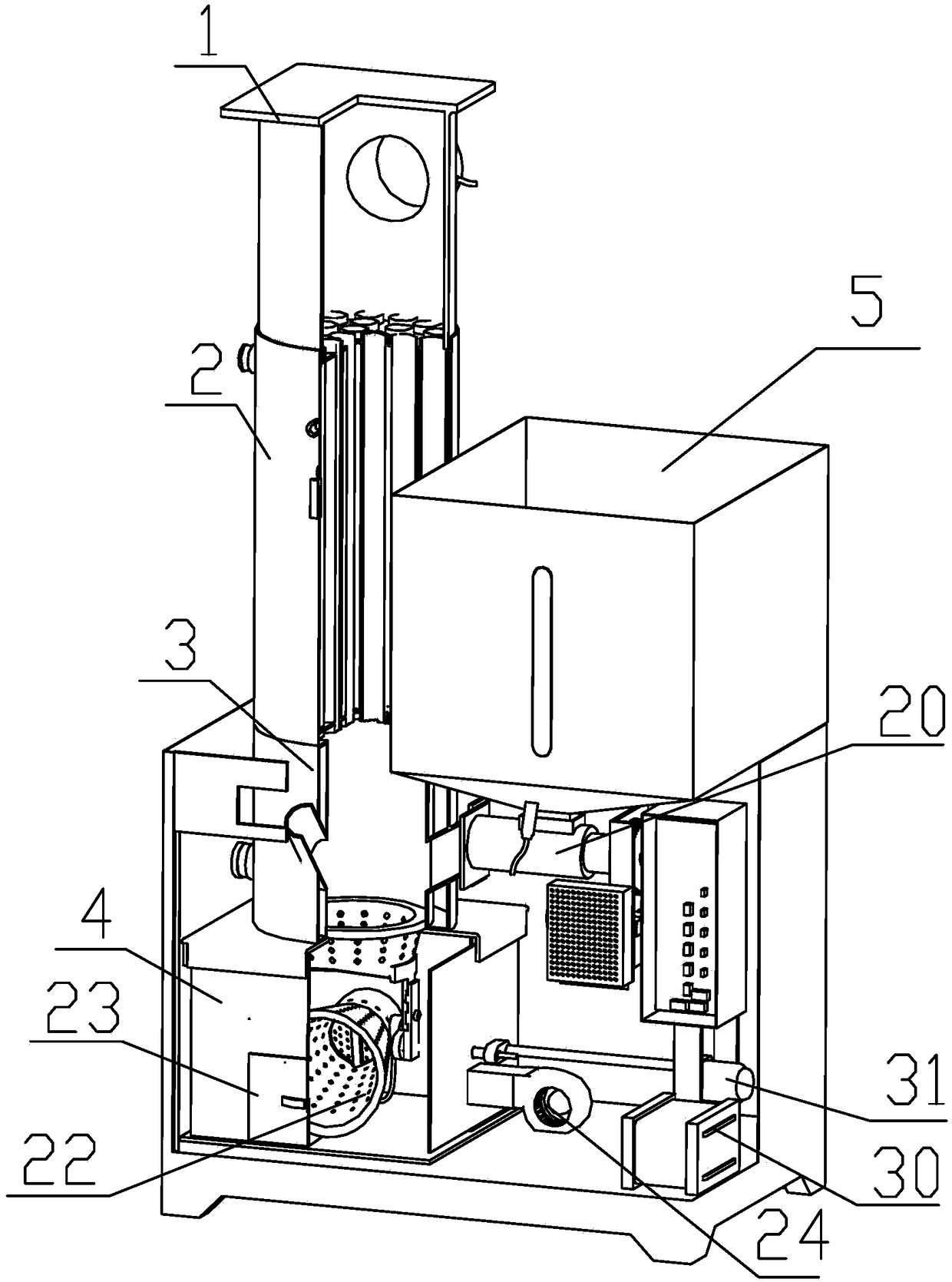

[0027] Such as figure 1 As shown, a biomass fuel combustion furnace includes a smoke collection hood 1, a heat exchange chamber 2, a combustion chamber 3, and a furnace chamber 4 connected sequentially from top to bottom, and also includes a hopper 5 and a control system.

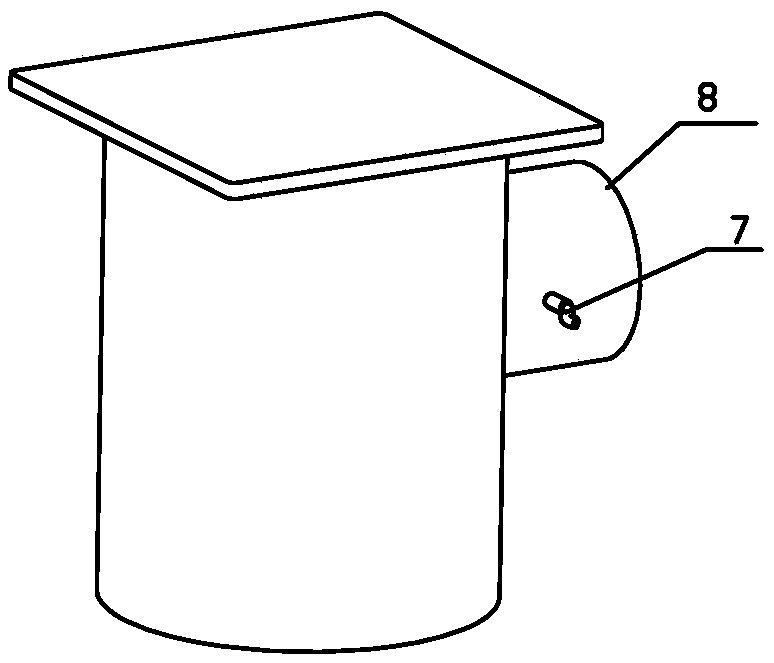

[0028] Such as figure 2 As shown, a chimney 8 is provided on one side of the smoke collecting hood 1, a temperature sensor 7 is provided at the smoke outlet of the chimney 8, and an induced draft fan is provided on the outlet side of the chimney 8, and the temperature sensor 7 and the induced draft fan are respectively connected to the control system. When it is detected that the temperature of the chimney 8 is too high, the feeding amount of the combustion chamber 3 is automatically reduced.

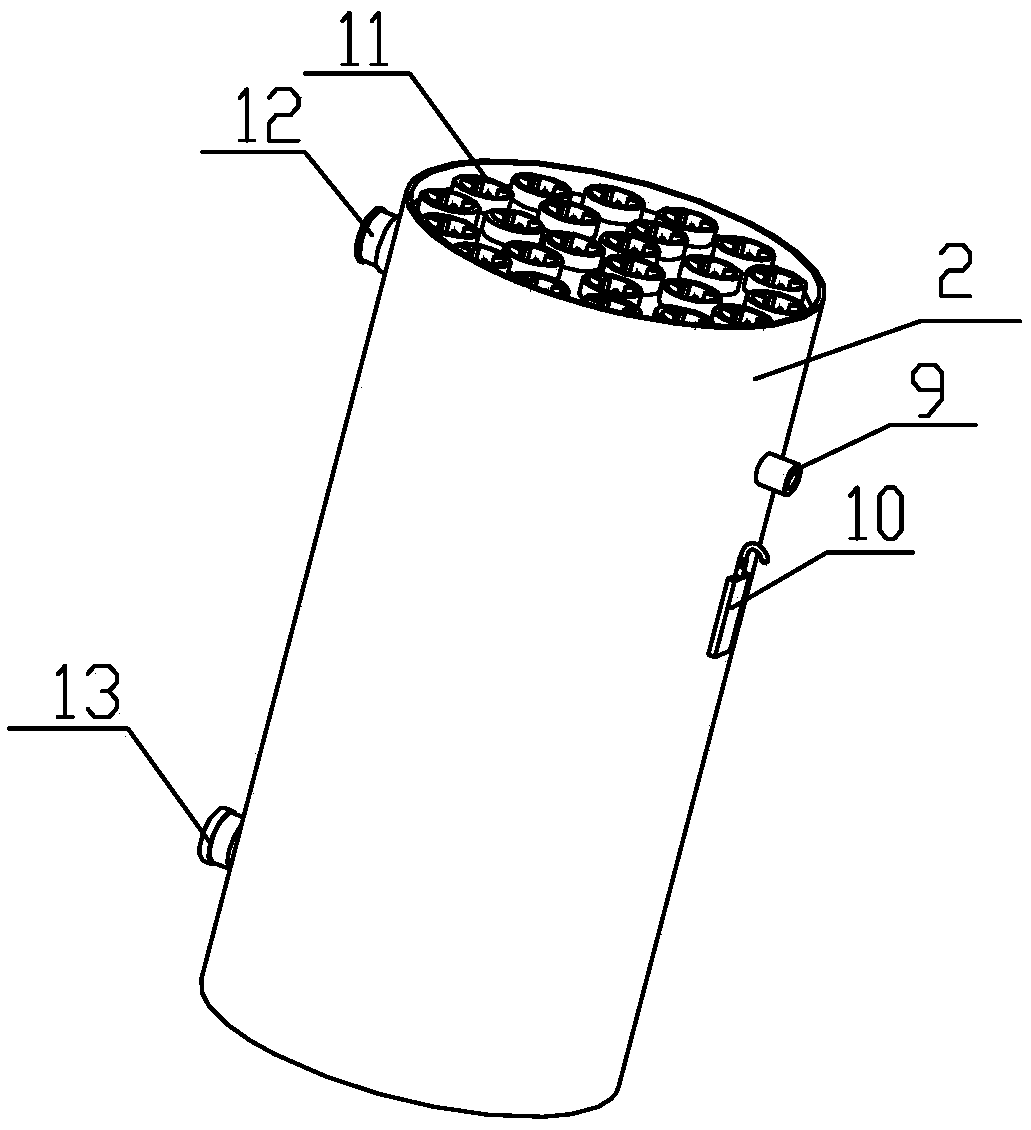

[0029] Such as image 3 As shown, the heat exchange chamber 2 includes a shell and an inner tube 11, several inner tubes 11 are regularly arranged in the shell, the bottom and top of the shell are welded and seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com