Mechanical arm wrist joint used under nuclear environment

A nuclear environment and mechanical technology, applied in the field of robotics, can solve problems such as difficult disassembly and maintenance, affecting transmission accuracy, and weak protection, so as to avoid collisions, ensure transmission accuracy, and eliminate transmission backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

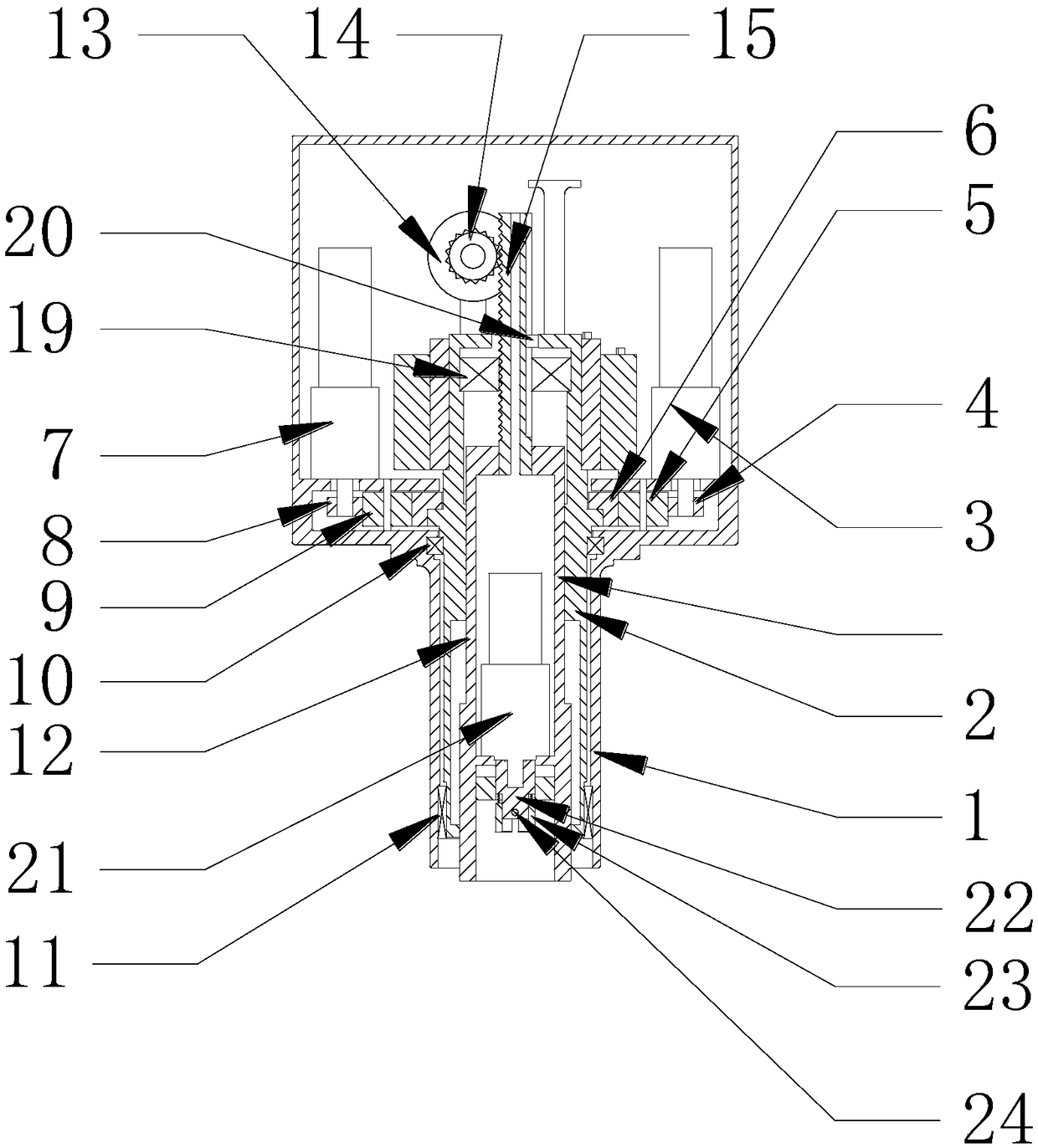

[0033] figure 1 It is a schematic diagram of the overall structure of the wrist joint of a robotic arm used in a nuclear environment according to the present invention.

[0034] In this example, if figure 1 As shown, a wrist joint of a manipulator used in a nuclear environment in the present invention mainly includes: a main structure 1, a revolving body 2 and a telescopic body 12;

[0035] The main structure 1 is installed with the rotary body 2, the rotary drive motor 3 and the counter torque motor 7, as well as the inlet flange 39 and the electric slip ring 29; the rotary body 2 is installed coaxially with the main structure 1, and the main The structure 1 is connected so that the rotary body 2 can perform rotary motion relative to the main structure 1; the rotary body 2 is connected with the output shaft of the rotary motor 3 through one or more stages of gear transmission, and is connected with the counter torque motor through one or more stages of gear transmission. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com