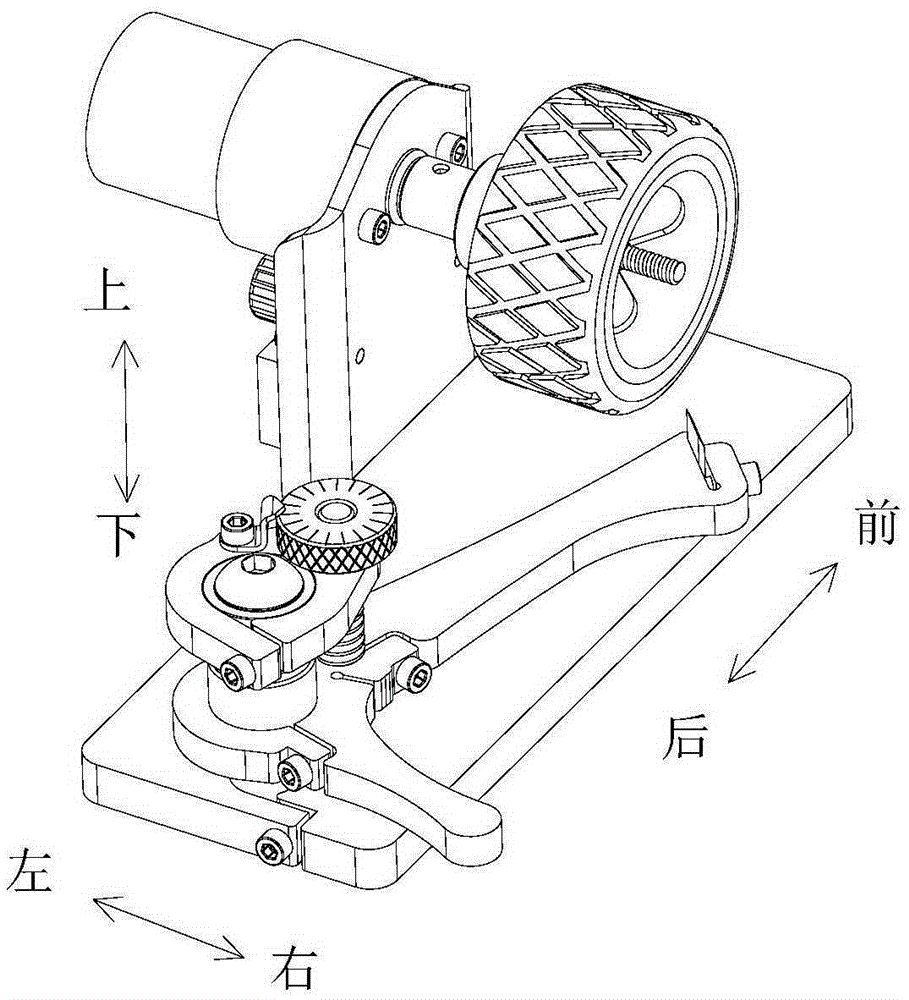

Model racing vehicle wheel turning tool

A wheel and turning technology, used in turning equipment, manufacturing tools, turning equipment, etc., can solve the problems of reducing the ground contact area, prone to errors, excessive spring tension movement, etc., to eliminate feed locking and reduce manufacturing costs. , Eliminate the effect of transmission backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

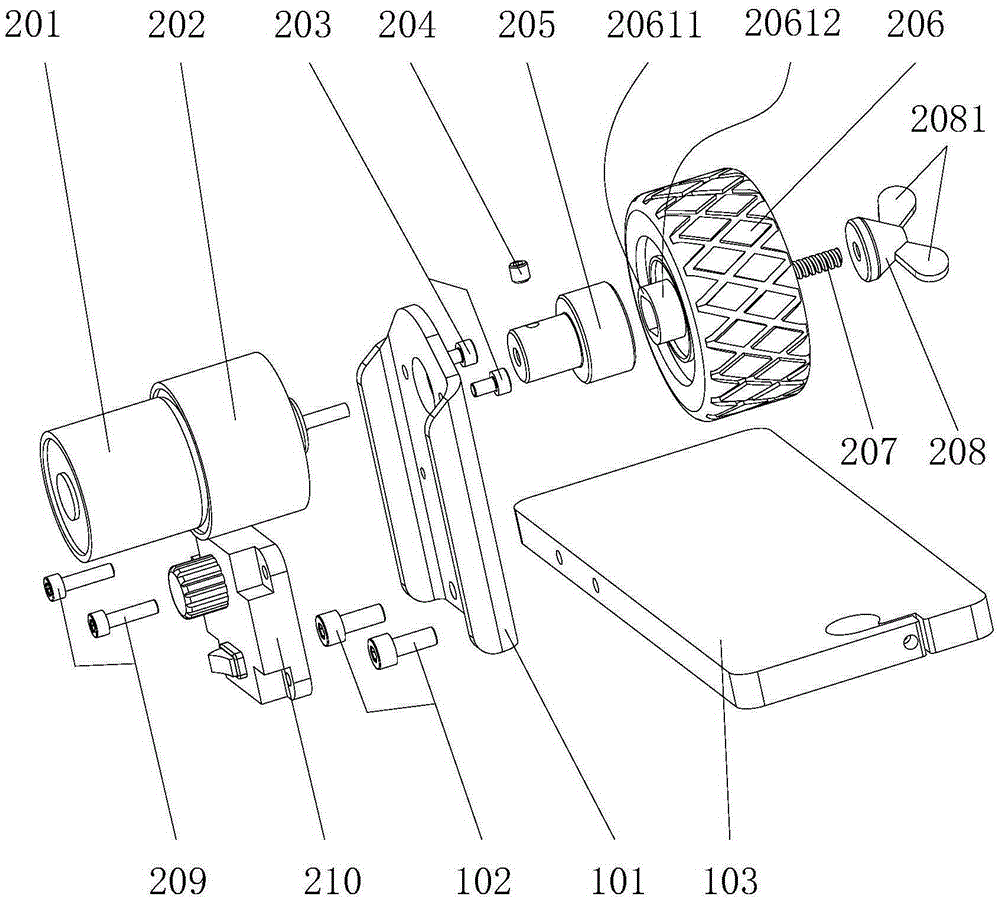

[0032] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

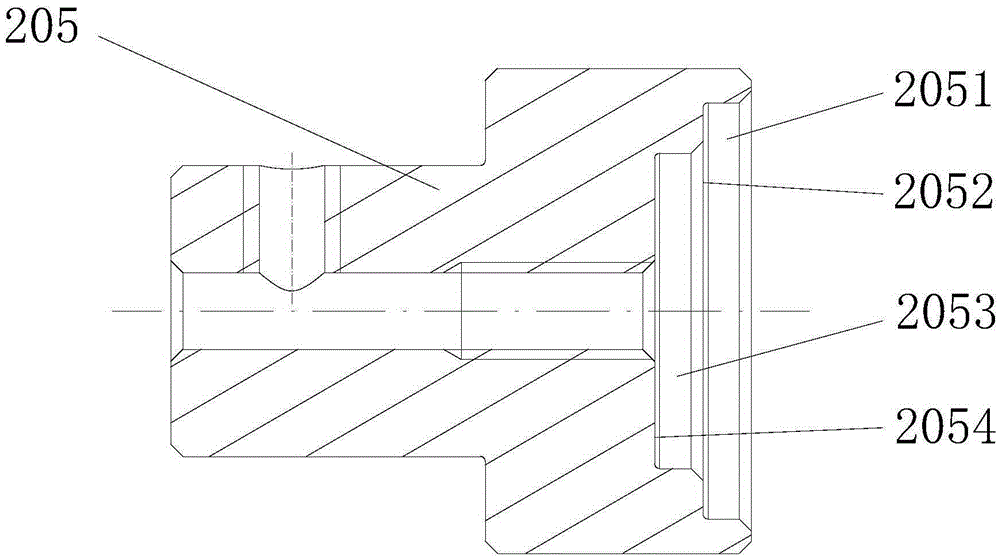

[0033] Before introducing this embodiment in detail, the structure of the wheel assembly 206 applicable to the present invention is described as follows, as figure 2 , Figure 4 and Figure 5 As shown, the wheel assembly 206 is composed of a rim 2061 and a tire 2062. The rim 2061 is generally a revolving body made of plastic or non-ferrous metal. On the lip, the leftmost part of the center of the rim 2061 is provided with a rim end face 20611 and a cylindrical rim step 20612 for axial positioning and radial positioning respectively when assembled on a model racing car. The axis of the rim step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com