Industrial robot repair and maintenance device

An industrial robot, inspection and maintenance technology, applied in the direction of workbench, manipulator, manufacturing tools, etc., can solve the problems that affect the maintenance work, the area of the inspection platform cannot be changed, and the robot cannot be placed on the platform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

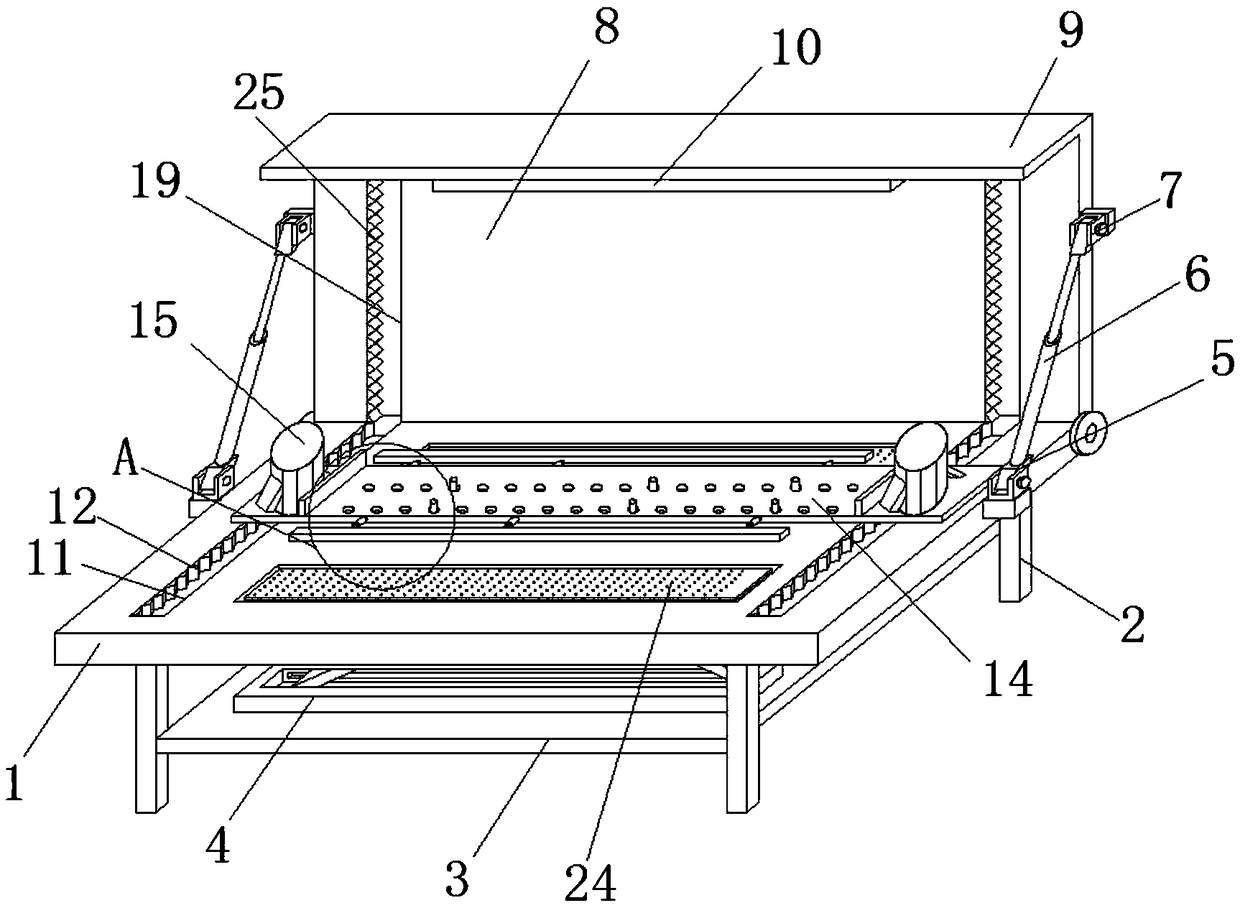

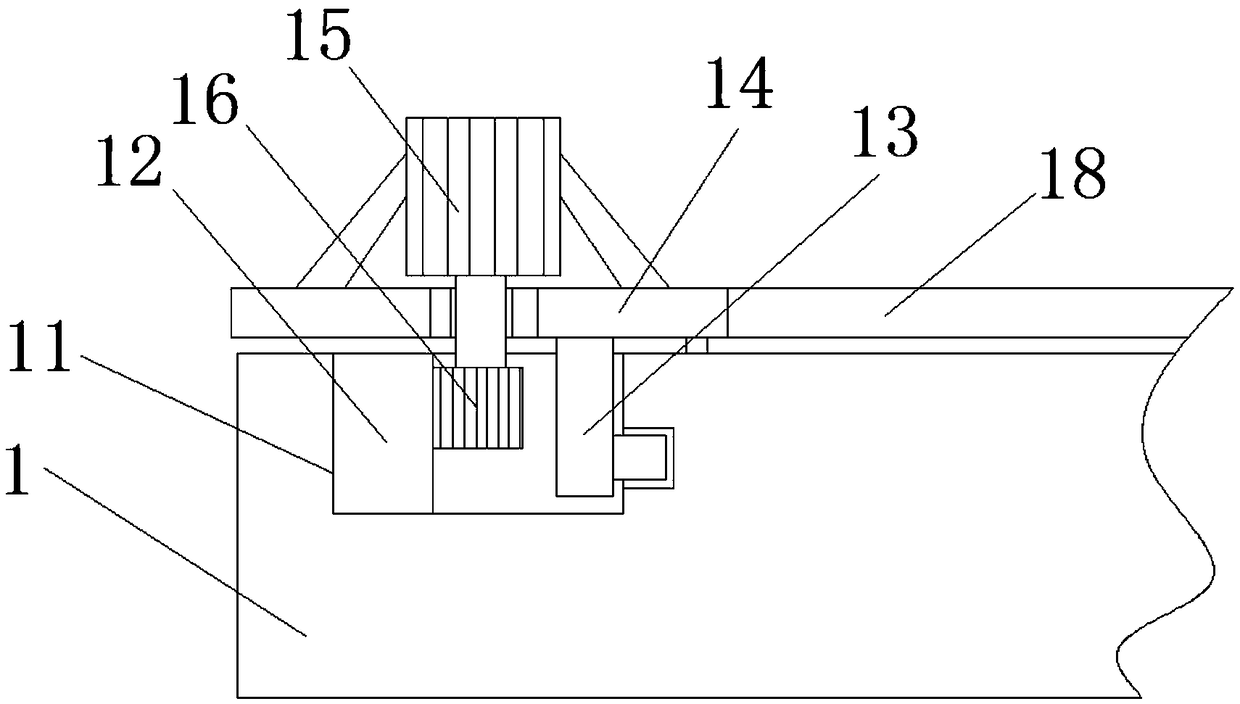

[0022] see Figure 1-4 , this embodiment provides an industrial robot inspection and maintenance device, including an inspection table 1, a support frame 2 is welded to the bottom of the inspection table 1, a mounting plate 3 is fixedly connected to the inner side of the support frame 2, and a scissor is fixedly installed on the top of the mounting plate 3. Type lifting platform 4, scissor lifting platform 4 runs through the maintenance platform 1, both sides of the maintenance platform 1 are fixedly connected with the first hinged seat 5, one side of the first hinged seat 5 is hinged with a hydraulic cylinder 6, and the hydraulic cylinder 6 is far away from the first hinged seat 5. One end of a hinged seat 5 is fixedly connected with a second hinged seat 7, the back of the maintenance platform 1 is hinged with an expansion board 8, and the expansion board 8 is fixedly connected with the second hinged seat 7, and the front of the maintenance platform 1 is provided with a drive ...

Embodiment 2

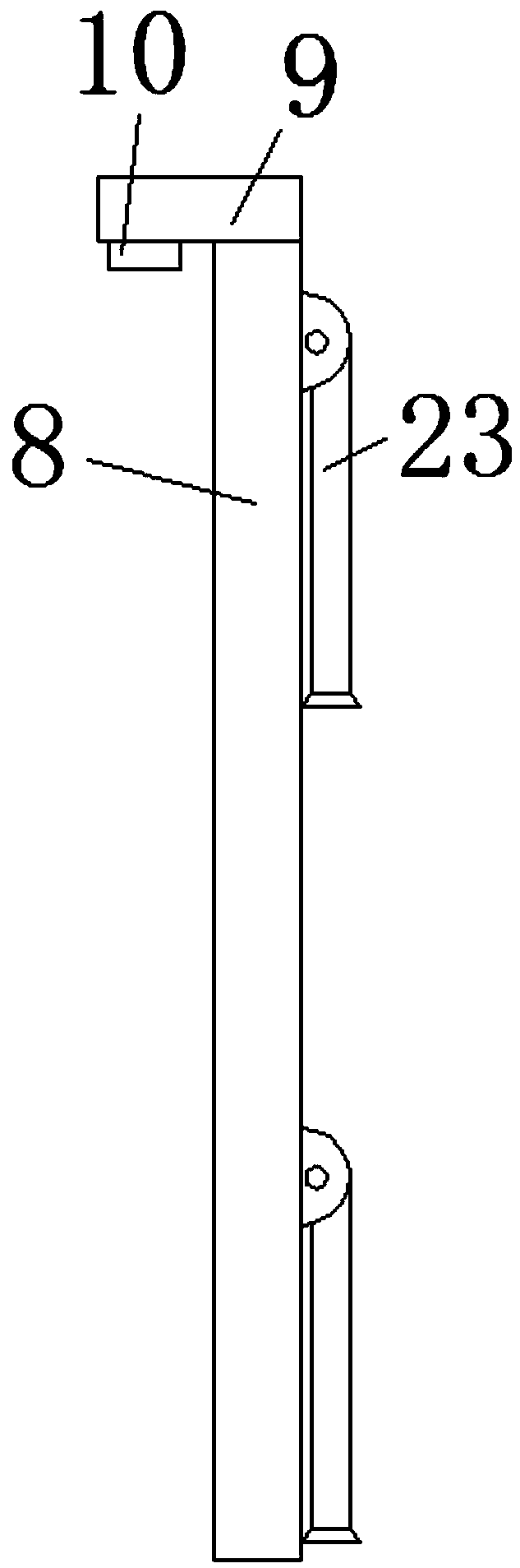

[0025] see Figure 1-4 , made further improvements on the basis of Embodiment 1: the top of the expansion board 8 is provided with a flange 9, and the bottom of the flange 9 is fixedly connected with a supplementary light 10, under the supplementary light of the supplementary light 10, the maintenance personnel The robot can be observed more clearly to facilitate the maintenance work. The back of the expansion board 8 is provided with a support leg 23, and one side of the support leg 23 is fixedly connected with a shock absorber. When the expansion board 8 is in a horizontal state, the support leg 23 has played a certain supporting role to prevent it from tilting when it bears weight.

[0026]Wherein, the top of scissor lift platform 4 is fixedly connected with anti-skid plate 24, and anti-skid plate 24 is the rubber plate with groove on the surface, has increased the friction between robot and scissor lift platform 4, has played to prevent robot The scissor lift table 4 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com