A microwave de-icing device for aircraft

A microwave and aircraft technology, applied in the field of aircraft microwave deicing devices, can solve the problems of low heating efficiency, unsatisfactory heating effect, scattered wave absorbing material distribution, etc., and achieve the effects of fast heating speed, high heat conversion efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

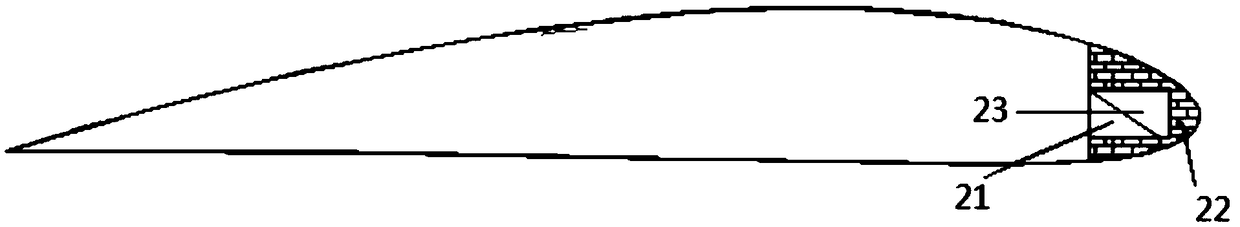

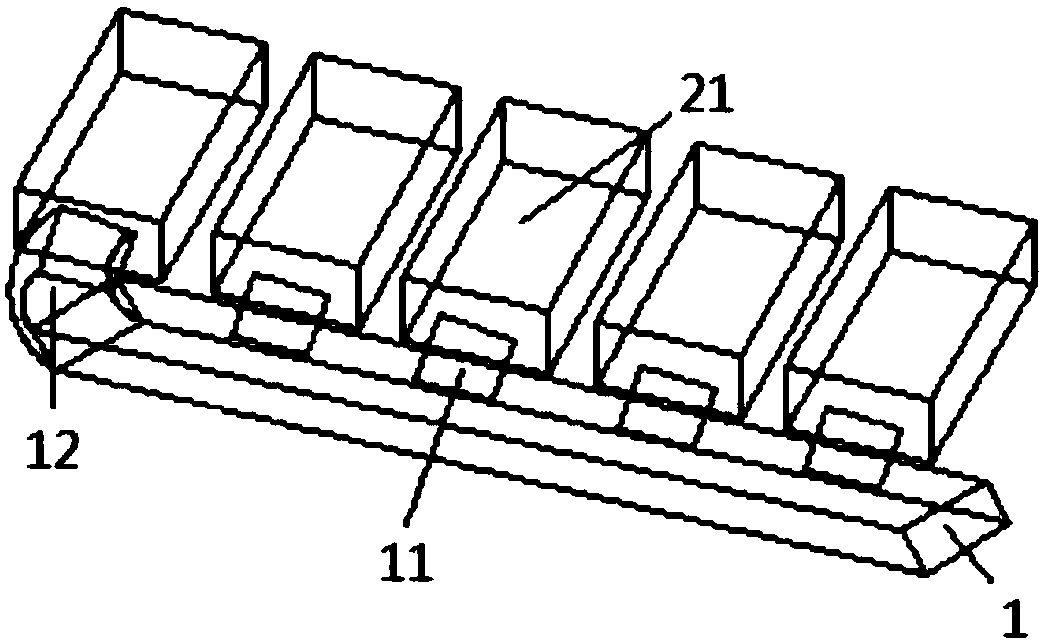

[0040] Such as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the reinforcing ribs 3 of this embodiment are arranged in parallel along the length direction of the wing, and the wave-absorbing load 2 is arranged between adjacent reinforcing ribs 3 on the wing, and each wave-absorbing load 2 includes a waveguide load cavity 21 and The heat dissipation material 22, the heat dissipation material 22 is coated on the periphery of the waveguide load cavity 21, the waveguide absorber 23 is arranged in the waveguide load cavity 21, and the long waveguide 1 passes through the spar 4 of the wing and is coupled to the The microwave input direction of each waveguide loading cavity 21 and each absorbing load 2 is perpendicular to the direction of the long waveguide 1 .

[0041] Because the wedge-shaped wave-absorbing material 24 is installed in the wave-absorbing load 2 , the microwave input into the waveguide load cavity 21 can be matched and absorbed, and the microwave energy is...

Embodiment 2

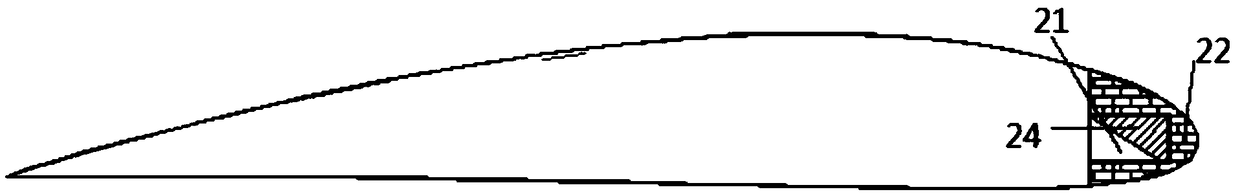

[0049] Such as figure 2 As shown, in this embodiment, when the power of the wave-absorbing load 2 is on the order of tens of watts, a wedge-shaped wave-absorbing material 24 is arranged in the waveguide load cavity 21, and the wave-absorbing material 24 is stacked and filled in a slope shape. The entire rectangular waveguide load cavity 21.

[0050] In Embodiment 1 and Embodiment 2, the microwave reflection coefficients of the two load cavity structures are very small, that is, the impedance matching is achieved, so that all the microwaves input into the load are absorbed by the absorbing material 24, so the heat absorption efficiency is high.

[0051] Other implementations are the same as in Example 1.

[0052] Absorbing material: traditional absorbing materials include ferrite, graphite, etc., and their disadvantage is high density; the absorbing material in this embodiment is carbon fiber, nano material, etc., which has the characteristics of low density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com