Special pasting machine for bowl films

A technology of laminating machine and bowl film, which is applied in the direction of packaging, wrapping paper shrinkage, wrapping paper, etc., can solve the problems of high labor intensity for washing dishes, too late to sanitize dishes, and not being environmentally friendly, so as to achieve the effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

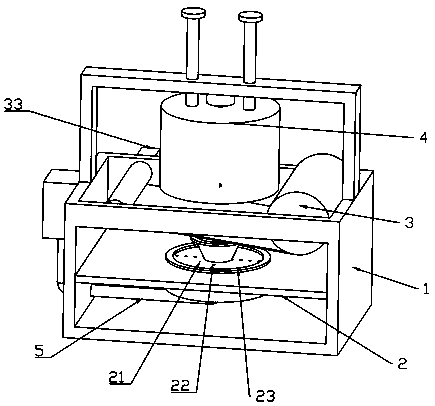

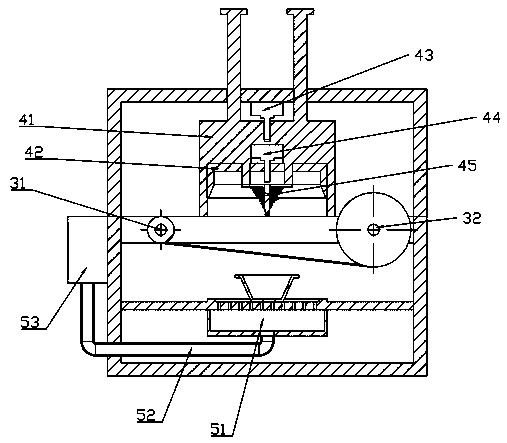

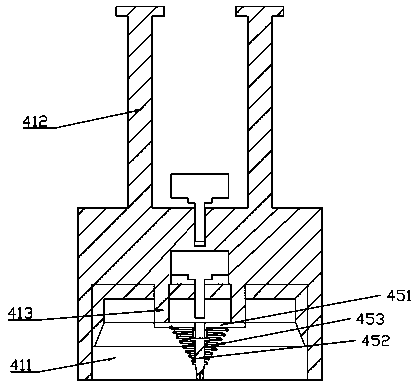

[0023] As shown in the figure, a special laminating machine for bowl film includes a base 1 on which a support plate 2, a bowl film feeding mechanism 3, a film pressing and cutting mechanism 4, and a film suction mechanism 5 are arranged.

[0024] Such as figure 1 As shown, the support plate 2 is provided with a film sticking station 21, and the film sticking station 21 is provided with a plurality of evenly distributed through holes 22, providing a working position for dish film sticking.

[0025] Such as Figure 1-2 As shown, the bowl film feeding mechanism 3 includes a drive wheel 31 and a discharge wheel 32 horizontally arranged on the base 1, and the drive wheel 31 and the discharge wheel 32 are respectively located on both sides above the film sticking station 21. Drive wheel 31 is connected with the 3rd driving motor 33; Bowl film adopts the preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com