Sterile hot air system for filling machine

A hot air system and mechanical technology, applied in ventilation systems, household heating, air conditioning systems, etc., can solve problems such as difficulty in cleaning, and achieve the effects of improving uniformity, improving stability, and convenient temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

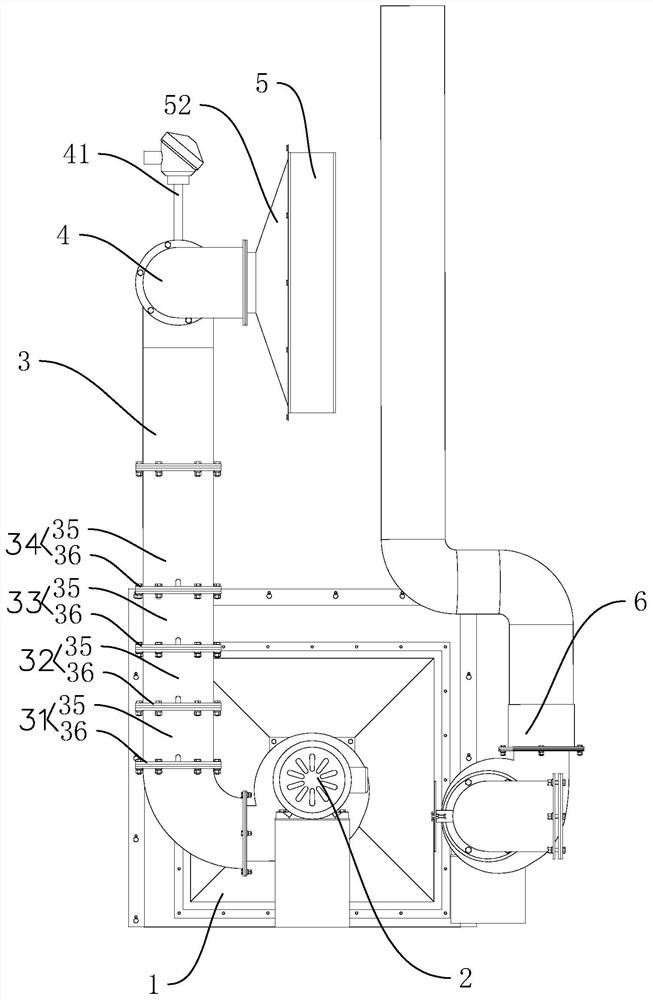

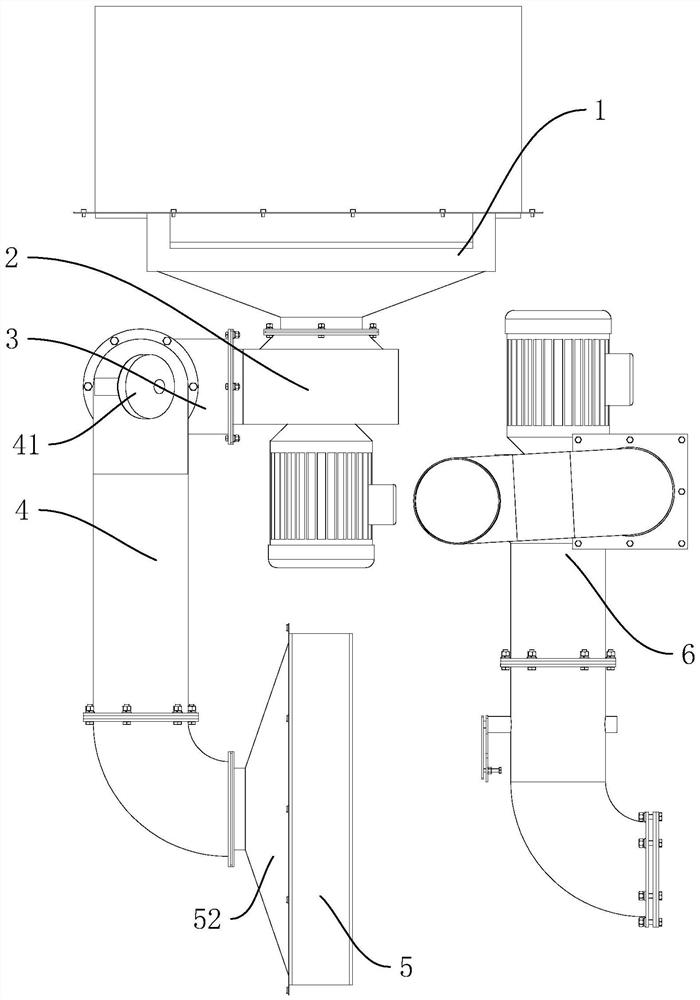

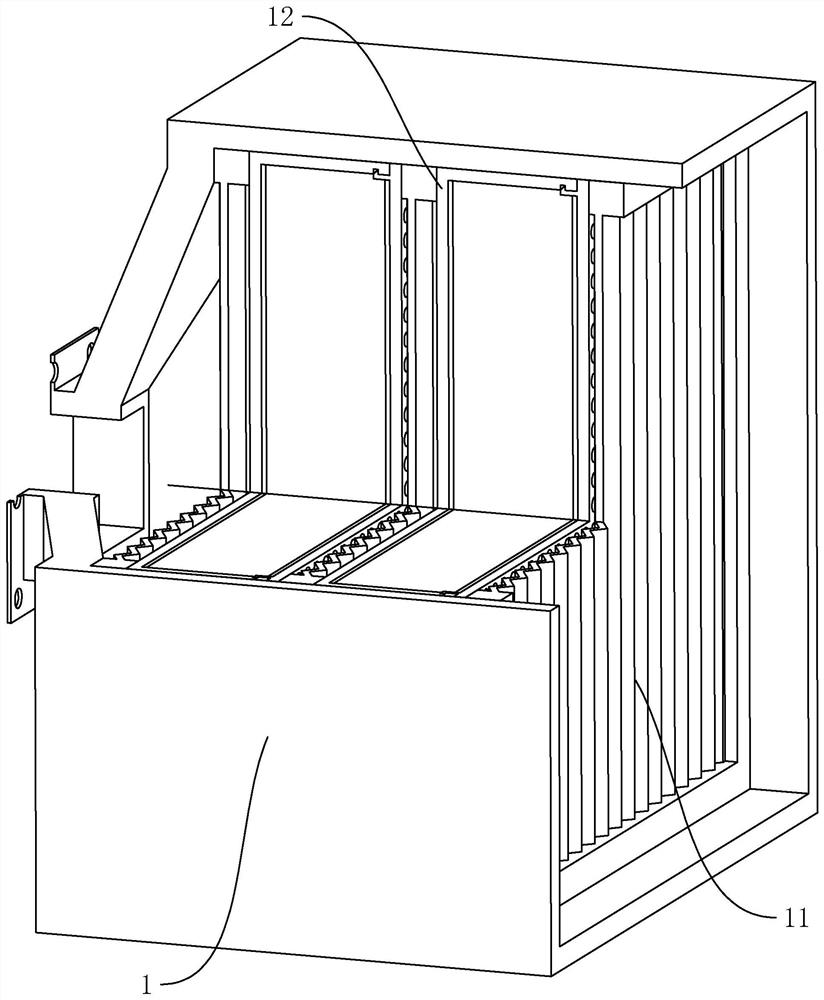

[0034] Aseptic hot air systems for filling machinery such as figure 1 , figure 2As shown, it includes an air inlet box 1 installed on the filling machine and communicated with the outside world, an exhaust fan 2 whose air inlet is connected to the air inlet box 1, a vertical pipeline 3 connected to the air outlet of the exhaust fan 2, and a vertical pipeline connected to the 3 the horizontal pipeline 4 at the top, the air outlet box 5 connected to the outlet of the horizontal pipeline 4, and the exhaust mechanism 6 independently installed on the filling machine; image 3 As shown, the air inlet box 1 is a structure with an open end, and a plurality of coarse filter screens 11 are clipped and fixed inside parallel to the open end; figure 1 As shown, the vertical pipeline 3 is provided with a multi-stage air treatment assembly, and the multi-stage air treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com