Improved sealing packaging container

A technology for sealing packaging and containers, applied in the field of containers, can solve problems such as the decline of sealing performance and the instability of anti-tripping structure, and achieve the effects of ensuring stability, stable anti-tripping structure and realizing sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

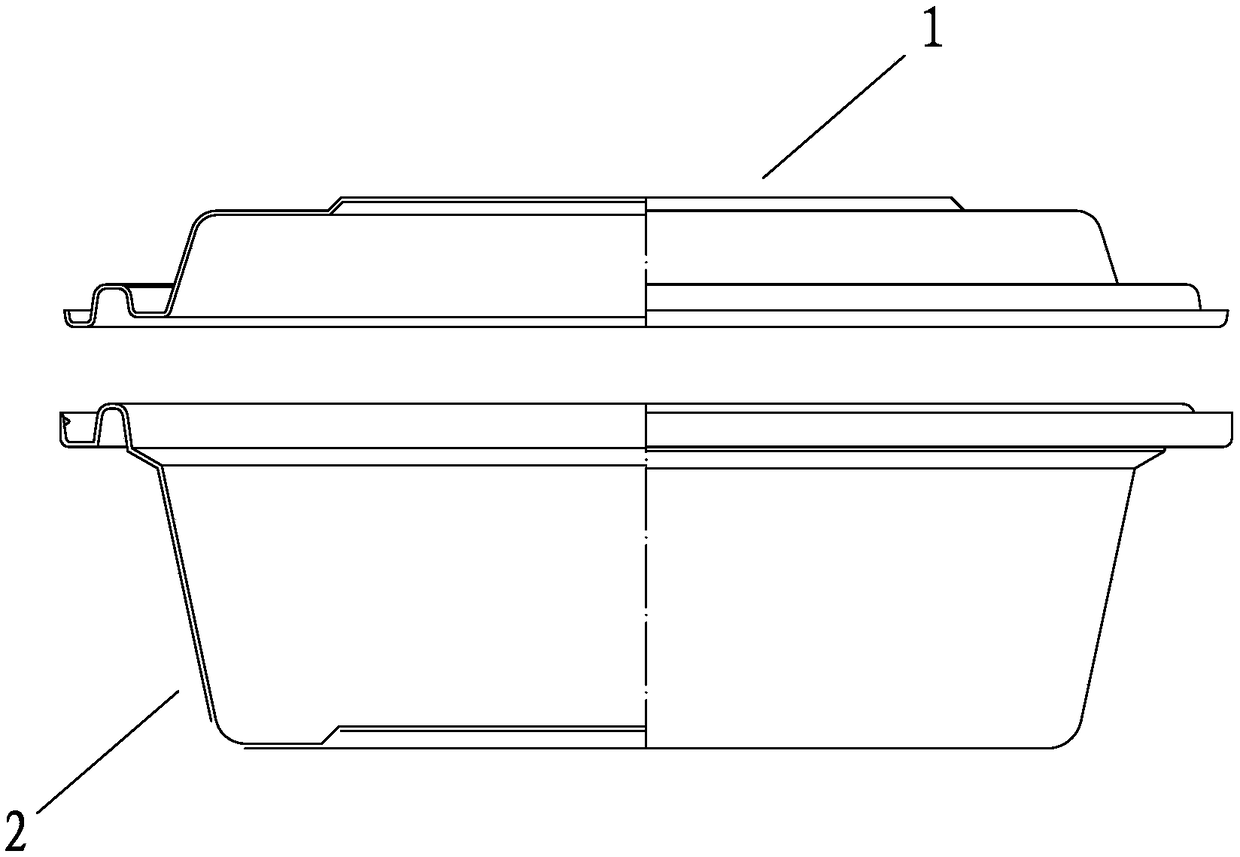

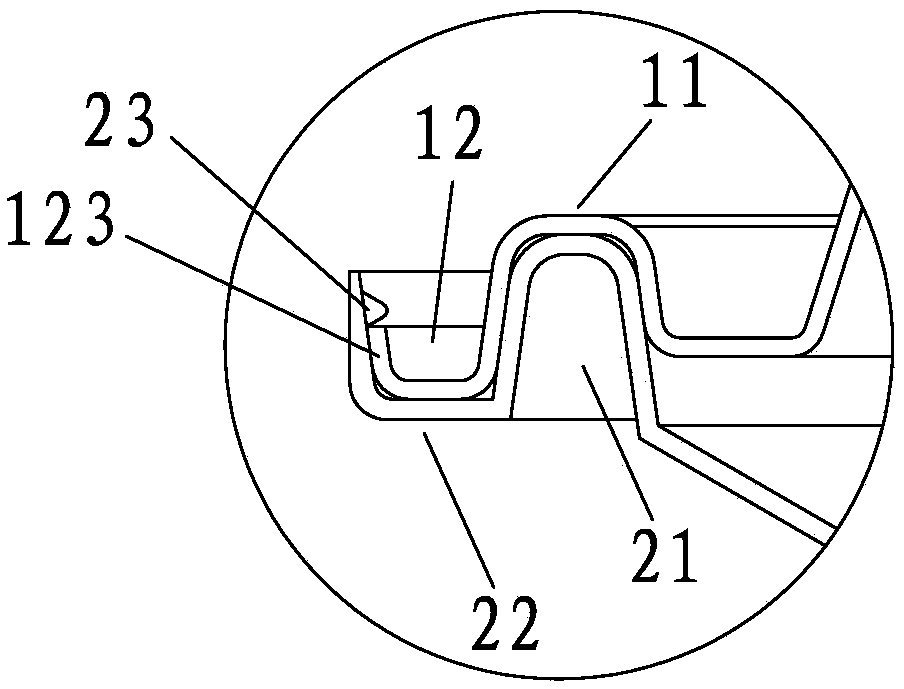

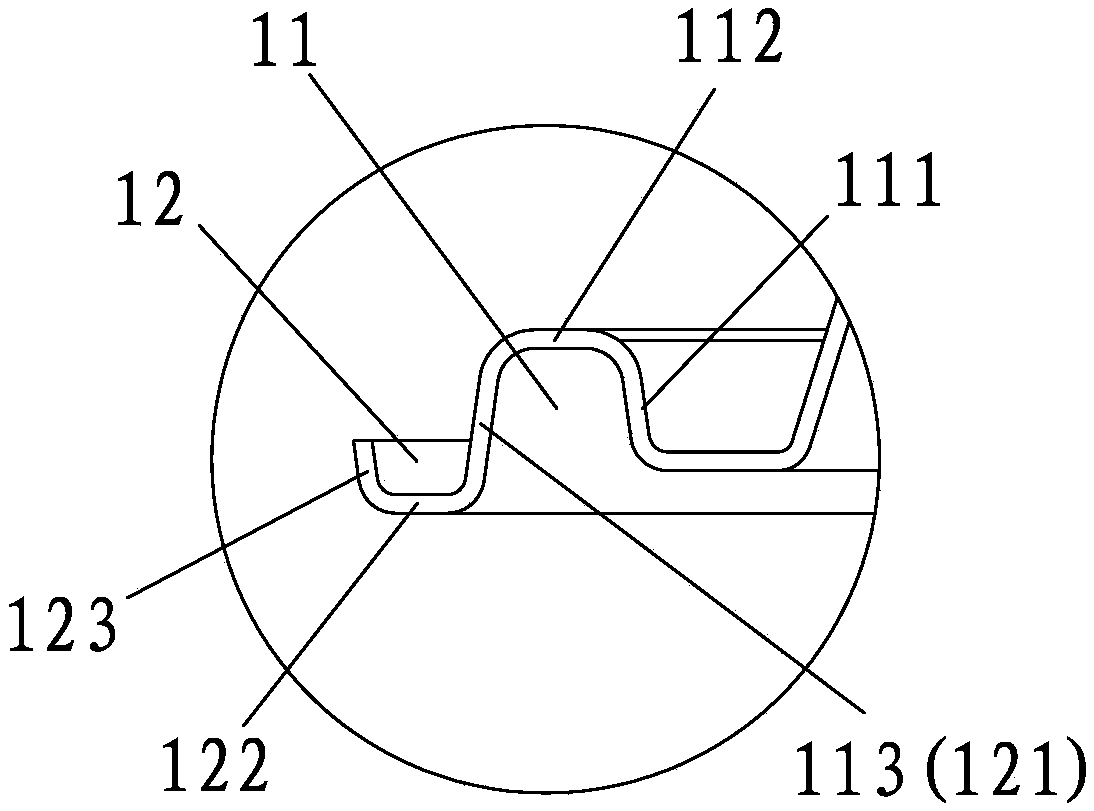

[0042] A kind of improved airtight packing container of the present invention, embodiment is as figure 1 As shown in -4, it includes a box cover 1 and an open box body 2. The edge of the box cover 1 extends outwards and is provided with an annular first inner fitting groove 11 with a notch downward. The first inner fitting The lower end of the outer groove wall 113 of the groove is bent and extended outwards and upwards in turn to form an annular first outer matching groove 12 with the notch upward; The ring-shaped second inner fitting groove 21, the lower end of the outer groove wall 213 of the second inner fitting groove is bent and extended outwards and upwards in turn to form an annular second outer fitting groove 22 with the notch upward; The first inner fitting groove 11, the first outer fitting groove 12, the second inner fitting groove 21 and the second outer fitting groove 22 are elastic fitting grooves; the outer fitting groove of the second outer fitting groove The...

Embodiment 2

[0050] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is only that: the inner groove wall of the first inner fitting groove 11 and the inner groove wall of the second inner fitting groove 21 both adopt a straight edge structure, and the inner groove wall of the first inner fitting groove 11 The inner groove wall is not in contact with the inner groove wall of the second inner fitting groove 21 .

Embodiment 3

[0052] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is only that: the inner groove wall of the first inner fitting groove 11 and the inner groove wall of the second inner fitting groove 21 both adopt a straight edge structure, and the inner groove wall of the first inner fitting groove 11 The inner groove wall is not in contact with the inner groove wall of the second inner fitting groove 21 , and the inner surface of the inner groove wall of the second inner fitting groove 21 is provided with a second inner pressing member 2111 . The sealing performance between the inner and outer groove walls of the first outer fitting groove 12 and the inner and outer groove walls of the second outer fitting groove 22 is enhanced by arranging the second inner pressing member 2111 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com