Steel wire clamping device and application thereof in heat treatment production of steel wire

A clamping device and steel wire technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems that affect the quality of steel wire products, easily burn people, and unsafe operation, so as to reduce the phenomenon of steel wire sparking and reduce the amount of waste products , flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The steel wire clamping device of the present invention and its application in steel wire heat treatment production are described in further detail below in conjunction with the accompanying drawings:

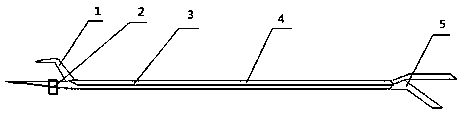

[0018] The steel wire clamping device of the present invention presses figure 1 , it is mainly composed of jaw 1, locking buckle 2, extension spring 3, pole 4 and handle 5; 3. Both ends of the extension spring 3 are respectively connected with the jaw 1 and the handle 5, and the jaw 1 is provided with a locking buckle 2.

[0019] The jaw 1 is a movable zigzag jaw, and the locking buckle 2 can effectively clamp the steel wire.

[0020] The steel wire clamping device is made of metal material.

[0021] The steel wire clamping device is made of 304 stainless steel.

[0022] The material of the jaw 1 is 304 stainless steel, the material of the pole 4 is 304 stainless steel pipe, and the handle 5 is made of plastic or a plastic sheath.

[0023] The application of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com