Prefabricated sheet pile combined bank revetment and construction method thereof

A construction method and prefabricated technology, applied in sheet pile walls, infrastructure engineering, coastline protection, etc., can solve the problems of huge investment, inability to construct, slow construction of cast-in-place piles, etc., saving investment, preventing soil leakage, Simple and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the unspecified implementation conditions are usually the conditions in routine experiments.

[0034] An assembled sheet pile combined bank revetment of the present invention comprises:

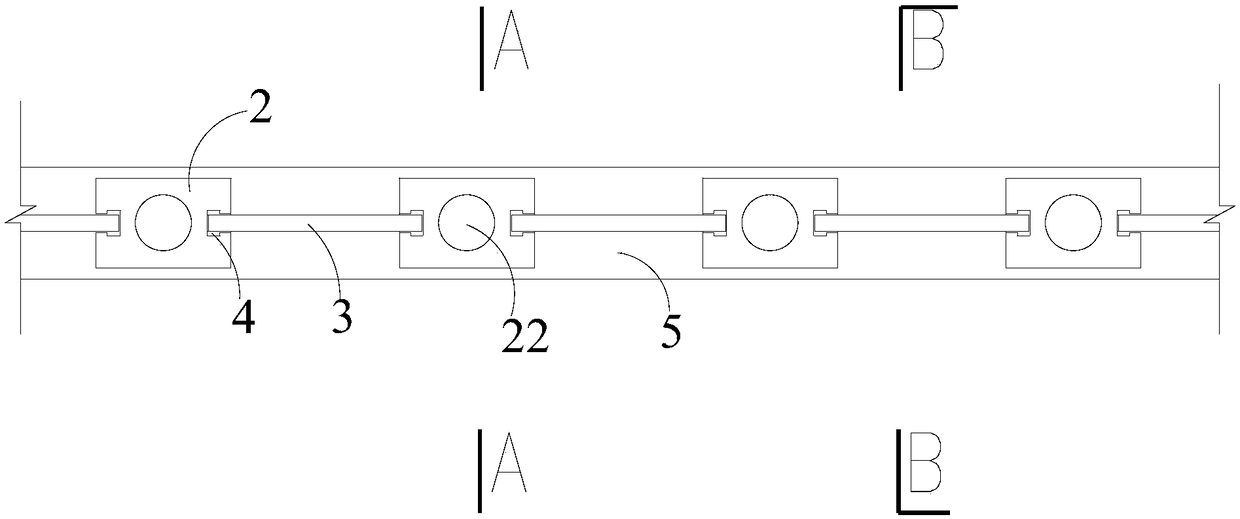

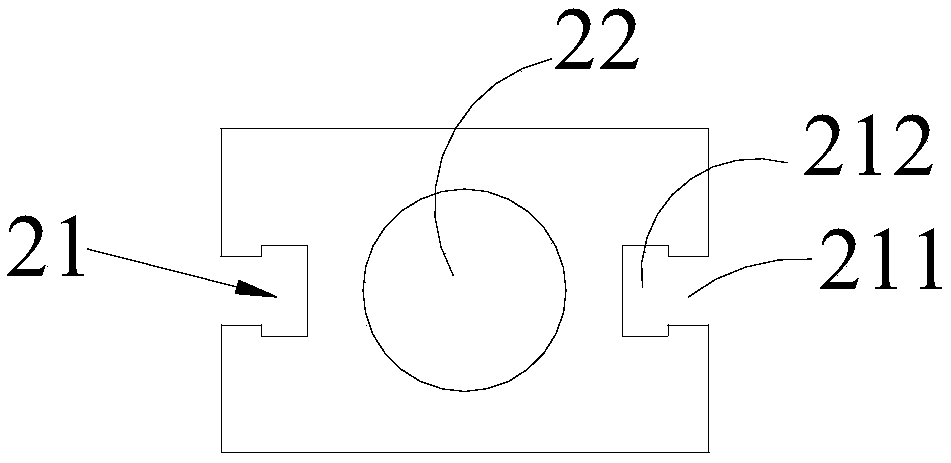

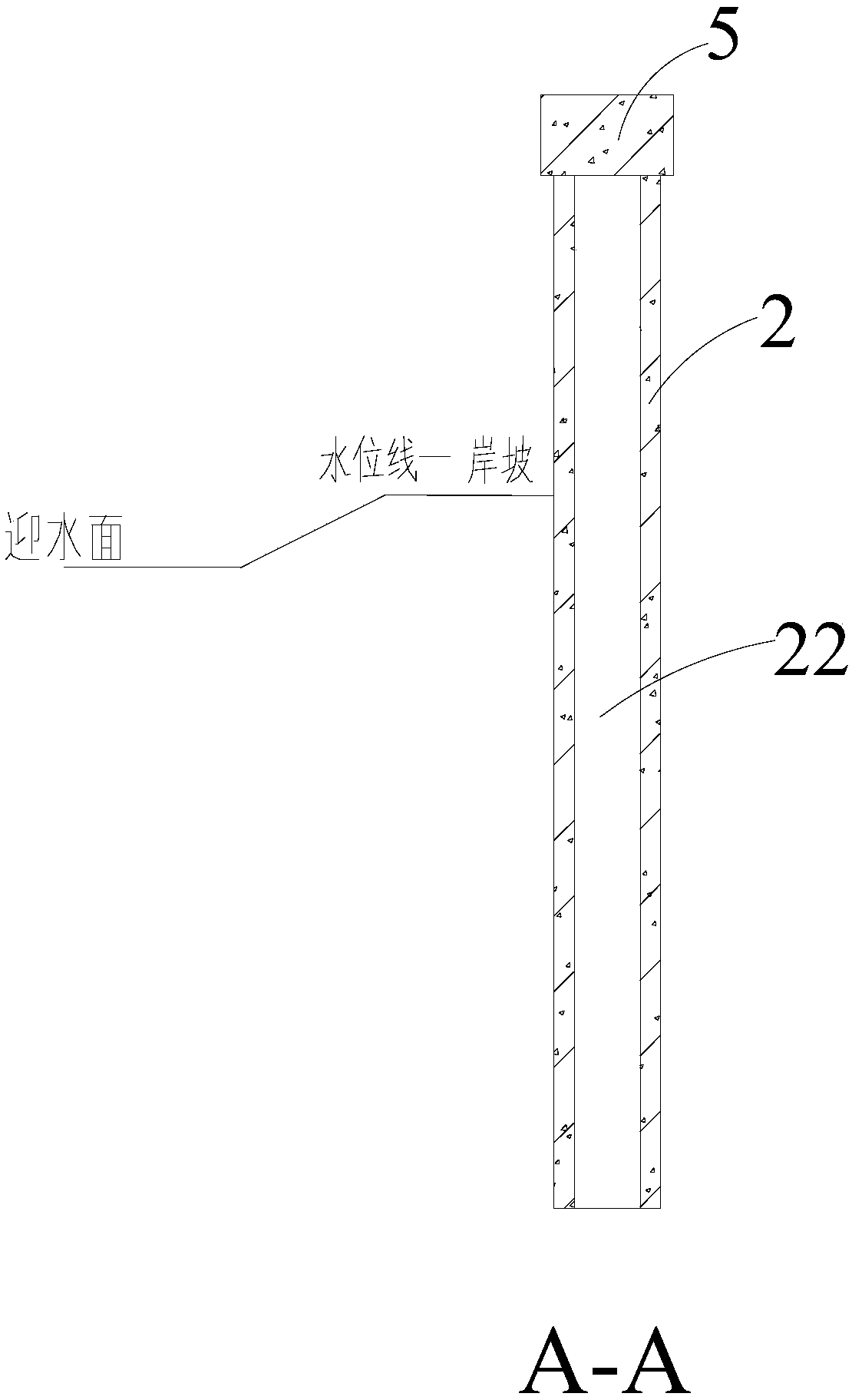

[0035] A plurality of PC wall piles 2 (PC is made of polycarbonate), and a plurality of PC wall piles 2 are arranged at intervals along the bank slope; grooves 21 are provided on opposite sides of two adjacent PC wall piles 2;

[0036] Multiple groups of prefabricated panels 3, the two ends of each group of prefabricated panels 3 are inserted in the grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com