Method and device for heating compressor through stator winding

A stator winding and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of poor heat transfer effect, large switching loss, etc., to reduce loss, improve reliability, increase The effect of control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

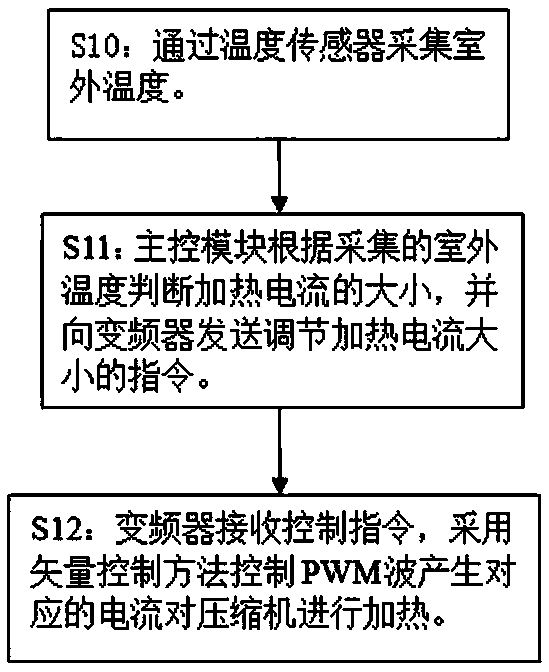

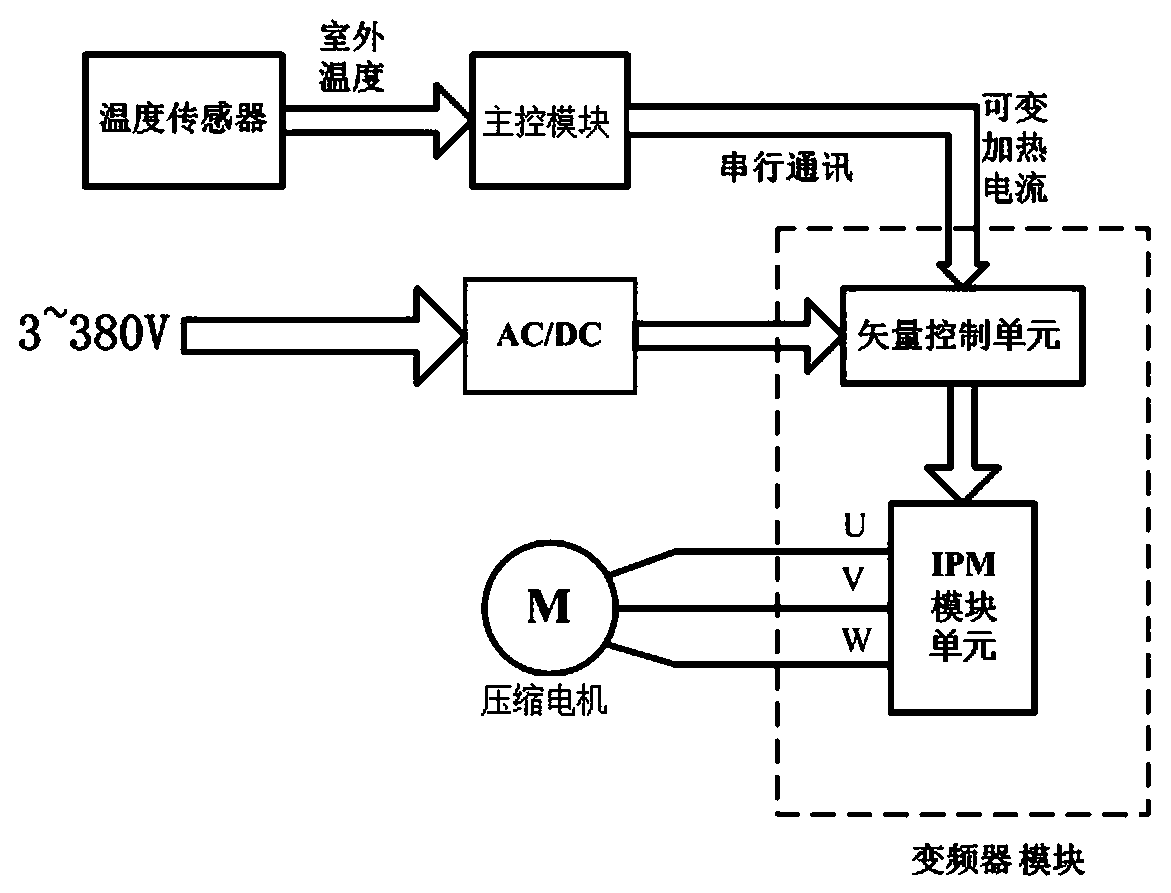

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the embodiments of the present invention and the accompanying drawings.

[0026] The present invention utilizes stator windings to heat the compressor. The stator winding heating technology is used to replace the scheme of heating the compressor with an electric heating belt. The heating current is controlled by the vector control method to solve the problem of poor and uneven heat transfer, and at the same time, reduce the Reduce the loss of the switch tube of the inverter IPM module.

[0027] The device for heating the compressor using the stator winding proposed by the present invention includes a device for detecting the outdoor ambient temperature T 1 A temperature sensor, a main control module and a frequency converter module. The main control module is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com