Shale gas conveying pipeline

A technology for transporting pipelines and shale gas, which is applied in the direction of pipeline support, pipeline protection, pipeline damage/wear prevention, etc. It can solve problems such as easy cracks on the pipeline wall, cumbersome installation and disassembly, and shale gas leakage, so as to facilitate normal transportation , Reduce the probability of damage and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

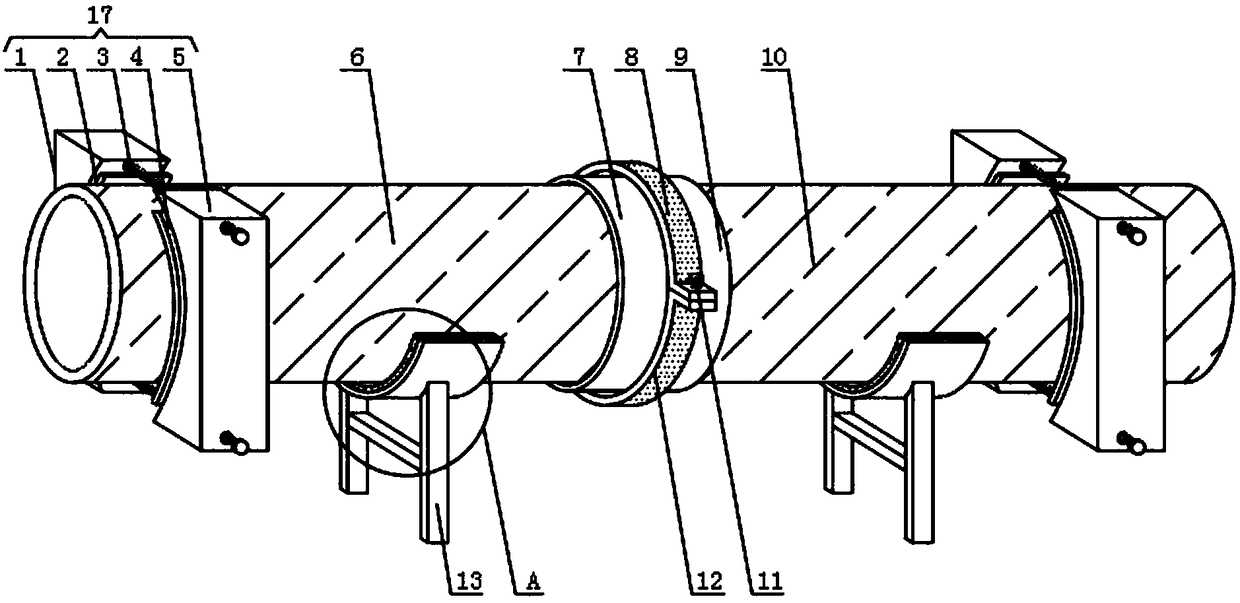

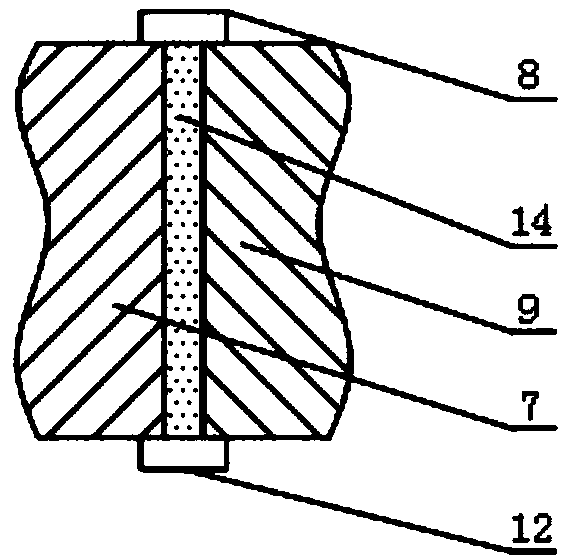

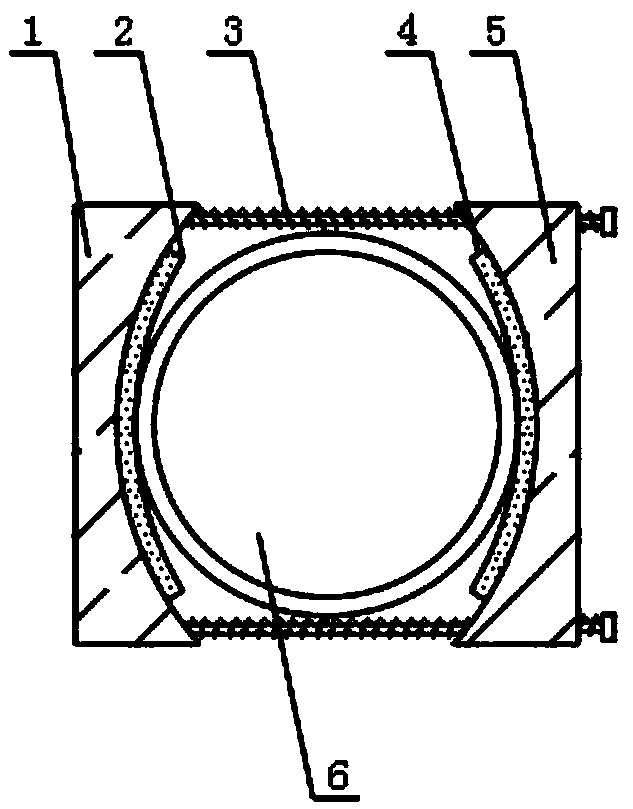

[0022] see Figure 1~4 , in an embodiment of the present invention, a shale gas transmission pipeline includes a first pipeline 6 and a sealing ring 14, one end of the first pipeline 6 is fixedly sleeved with a first fastening ring 7, and the outside of the first pipeline 6 is clamped A protective device 17 is combined, and the protective device 17 includes a first fixed seat 1, a first protective pad 2, a first fastening bolt 3, a second protective pad 4 and a second fixed seat 5, and one end sleeve of the first fastening bolt 3 The first fixed seat 1 is connected, and the other end of the first fastening bolt 3 is sleeved with the second fixed seat 5, the first fixed seat 1 and the second fixed seat 5 are fixedly connected by the first fastening bolt 3, and the second fixed seat 5 A fixed seat 1 and first protective pads 2 are fixed by an adhesive, the front surface of the first fixed seat 1 is fixed with the first protective pad 2, and the rear surface of the second fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com