Error detecting tool for dimension of circumferential hole position

A dimensional error and detection tool technology, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems of large size of the measuring device and low measurement accuracy, and achieve the effect of high measurement accuracy, multiple functions, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be further described below in conjunction with the accompanying drawings.

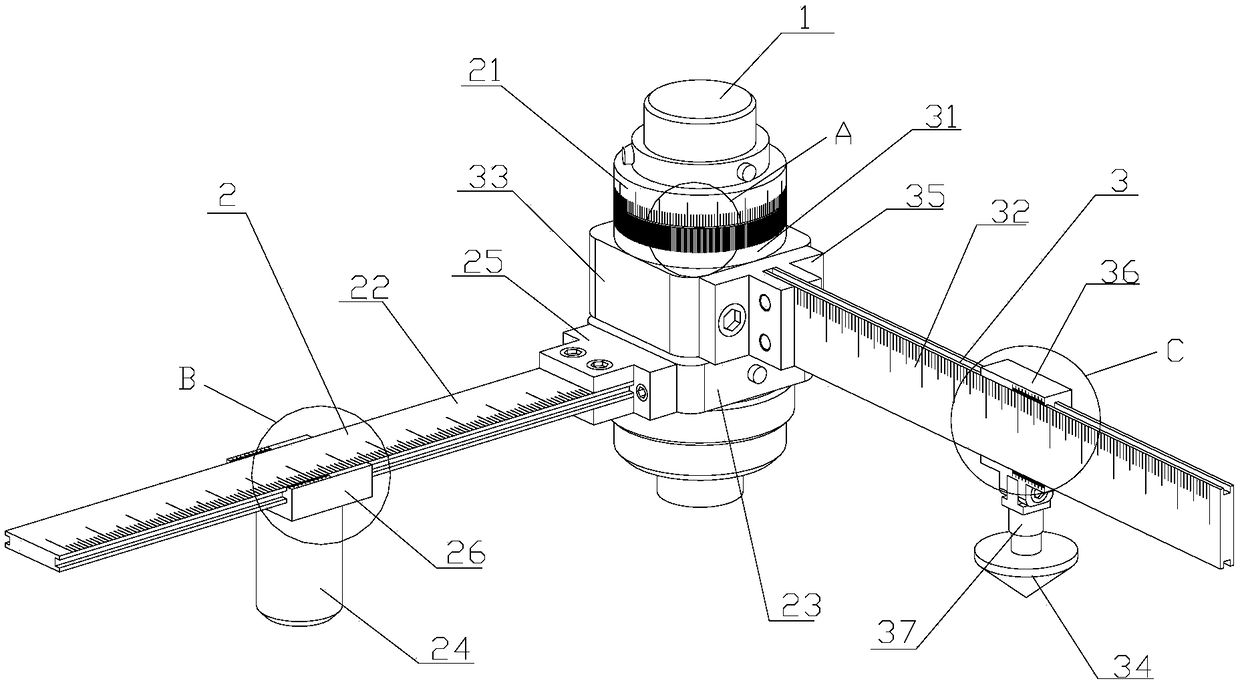

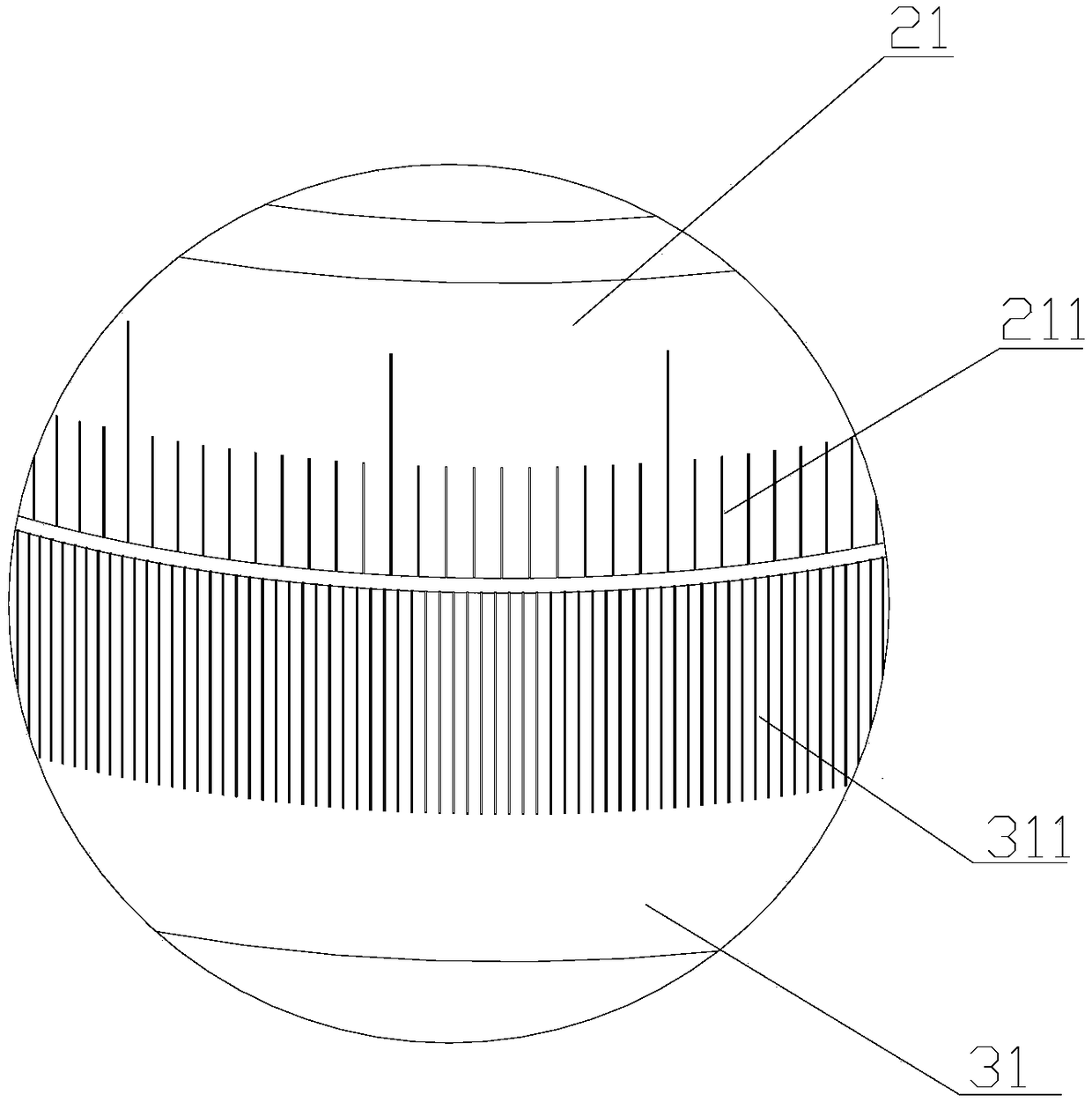

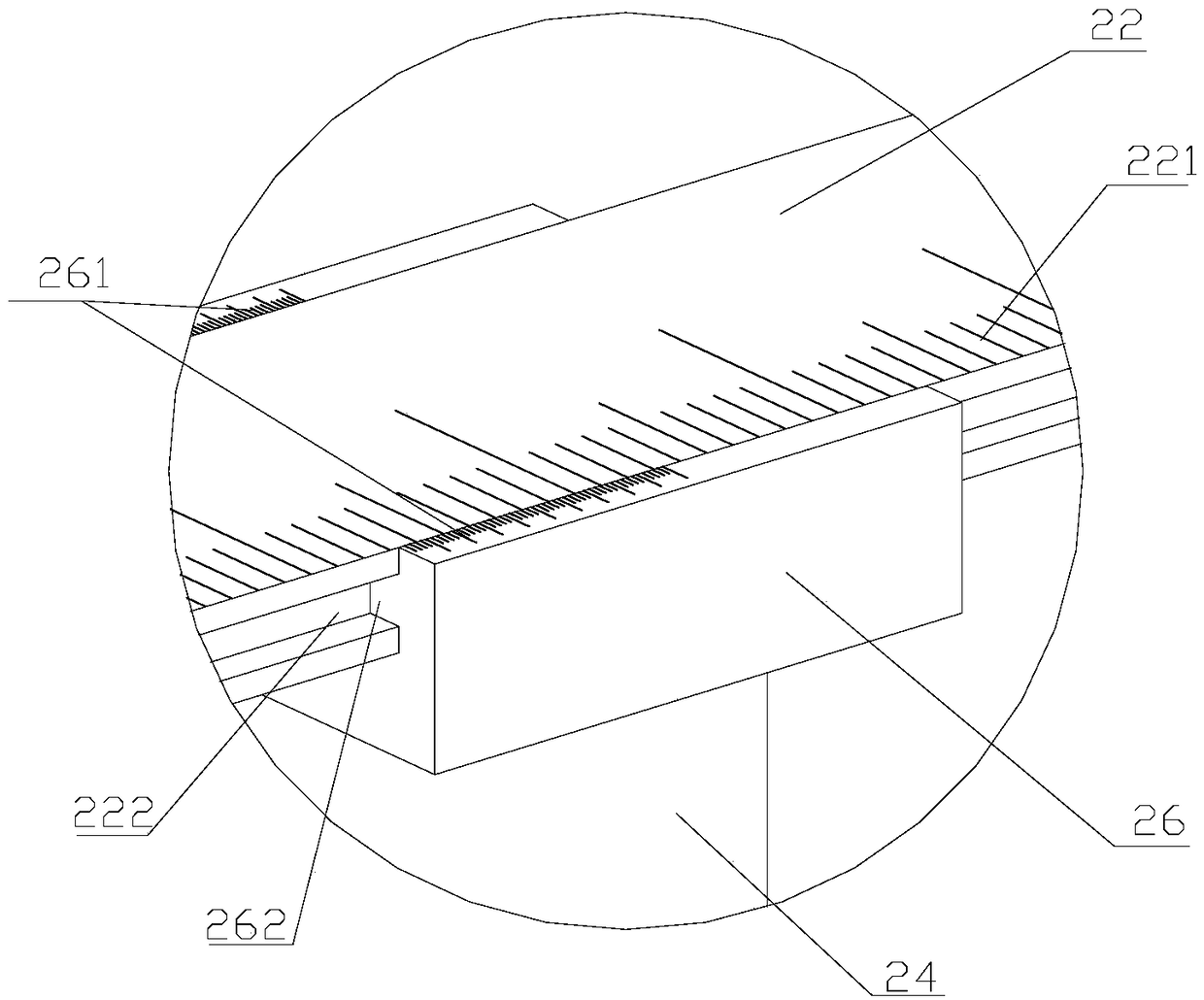

[0033] like Figure 1-9 As shown, this embodiment provides a circumferential hole position and size error detection tool, including a central shaft 1, on which a reference measurement assembly 2 and a movable measurement assembly 3 are arranged, and the reference measurement assembly 2 is fixedly arranged on the central shaft 1 , the activity measuring assembly 3 is rotatably arranged on the central shaft 1 .

[0034]The central axis 1 is a stepped axis. In this embodiment, the central axis 1 has at least 5 levels, and from top to bottom are I-axis 11, II-axis 12, III-axis 13, IV-axis 14 and V-axis 15. Preferably, I The outer diameters of shaft 11 , shaft II 12 , shaft III 13 and shaft IV 14 increase sequentially from top to bottom, and the outer diameter of shaft V 15 is smaller than that of shaft IV 14 . More preferably, a VI shaft 16 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com