Non-destructive experimental evaluation method for damage degree of heterogeneous compact rock

A technology of damage degree and compact rock, which is applied in the direction of material inspection products, instruments, and nuclear magnetic resonance analysis, etc., can solve problems such as poor reliability, large differences in physical and mechanical properties, and inability to effectively evaluate the influence of working fluids. Efficiency, the effect of improving evaluation and prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

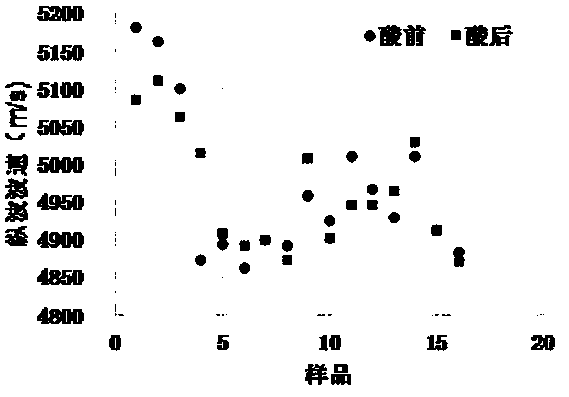

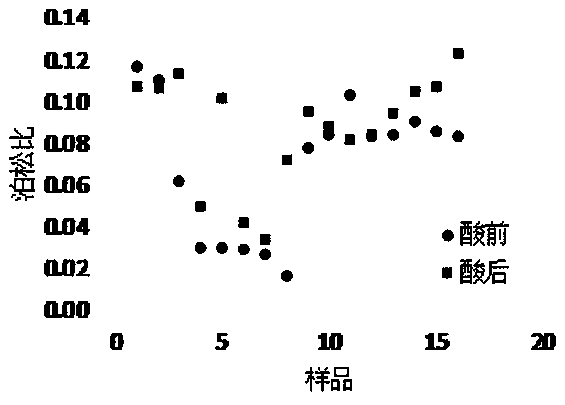

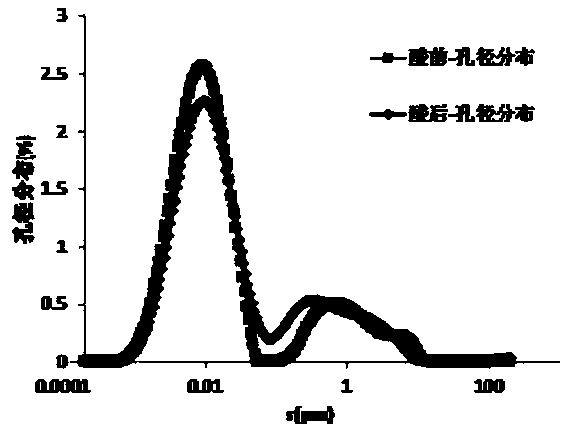

[0050] Taking the acid damage evaluation of heterogeneous tight sandstone in eastern Sichuan as an example, the non-destructive experimental evaluation method for acid damage of heterogeneous reservoirs provided by the present invention is adopted, and the specific process is as follows:

[0051] (1) Test the initial acoustic wave velocity of the rock sample, and convert it into the initial dynamic Young's modulus and initial dynamic Poisson's ratio of the rock sample).

[0052] A. Prepare a standard cylinder rock sample that meets the experimental conditions. For heterogeneous tight sandstone full-diameter cores, a cylindrical sample with a diameter of 25 mm is radially drilled, and the length and diameter of the rock sample are kept at 2:1 to avoid end effects. The parallelism of the two end faces must be kept within 0.02mm, and the perpendicularity between the end face and the axis must be within 0.05mm;

[0053] B. Put the rock sample in a drying oven and dry it at 70-90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com