Watch winding device

A watch and winding technology, which is applied in the direction of automatic winding, clocks, and ratchet mechanisms of clockwork, etc., can solve problems such as clockwork damage and impact on work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

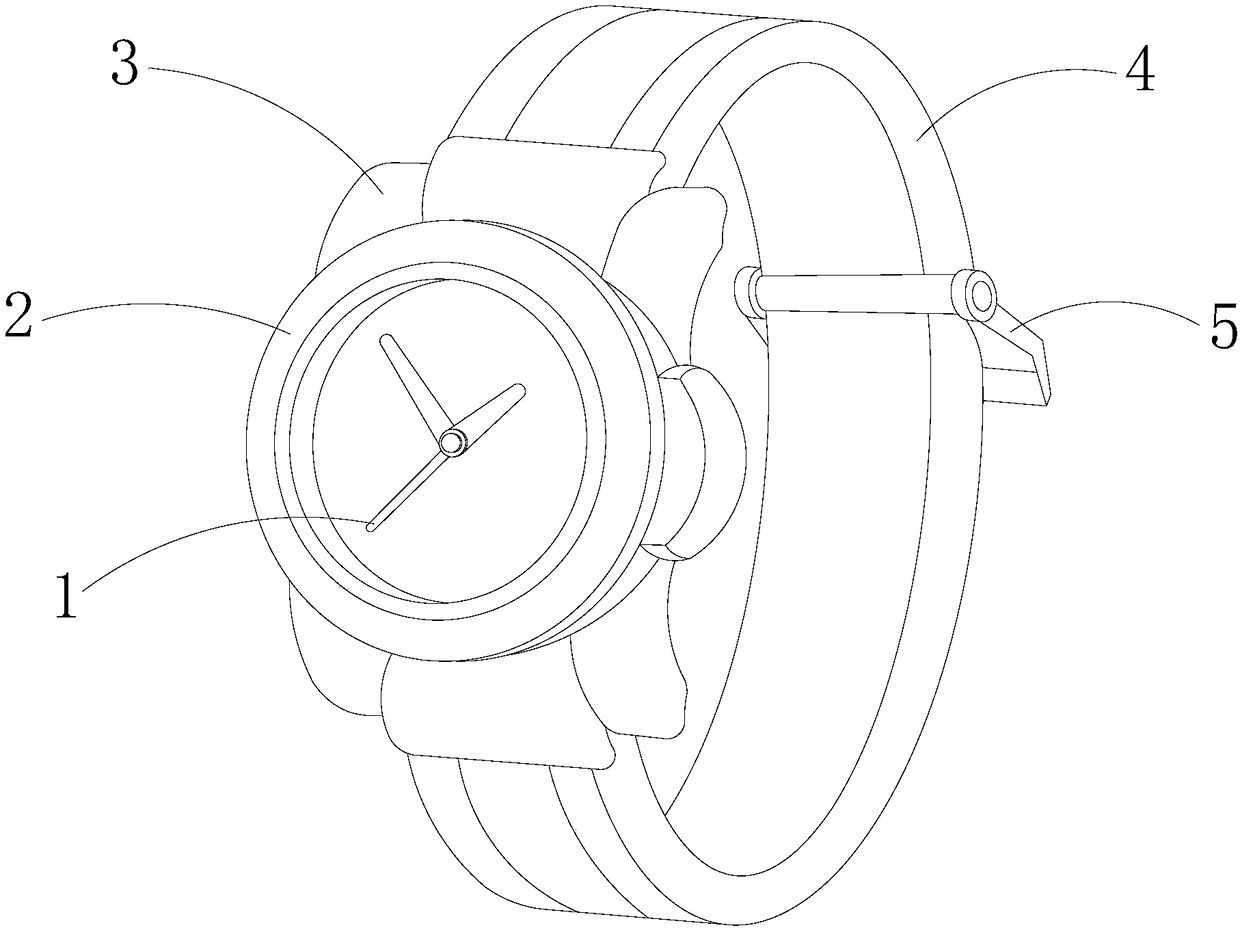

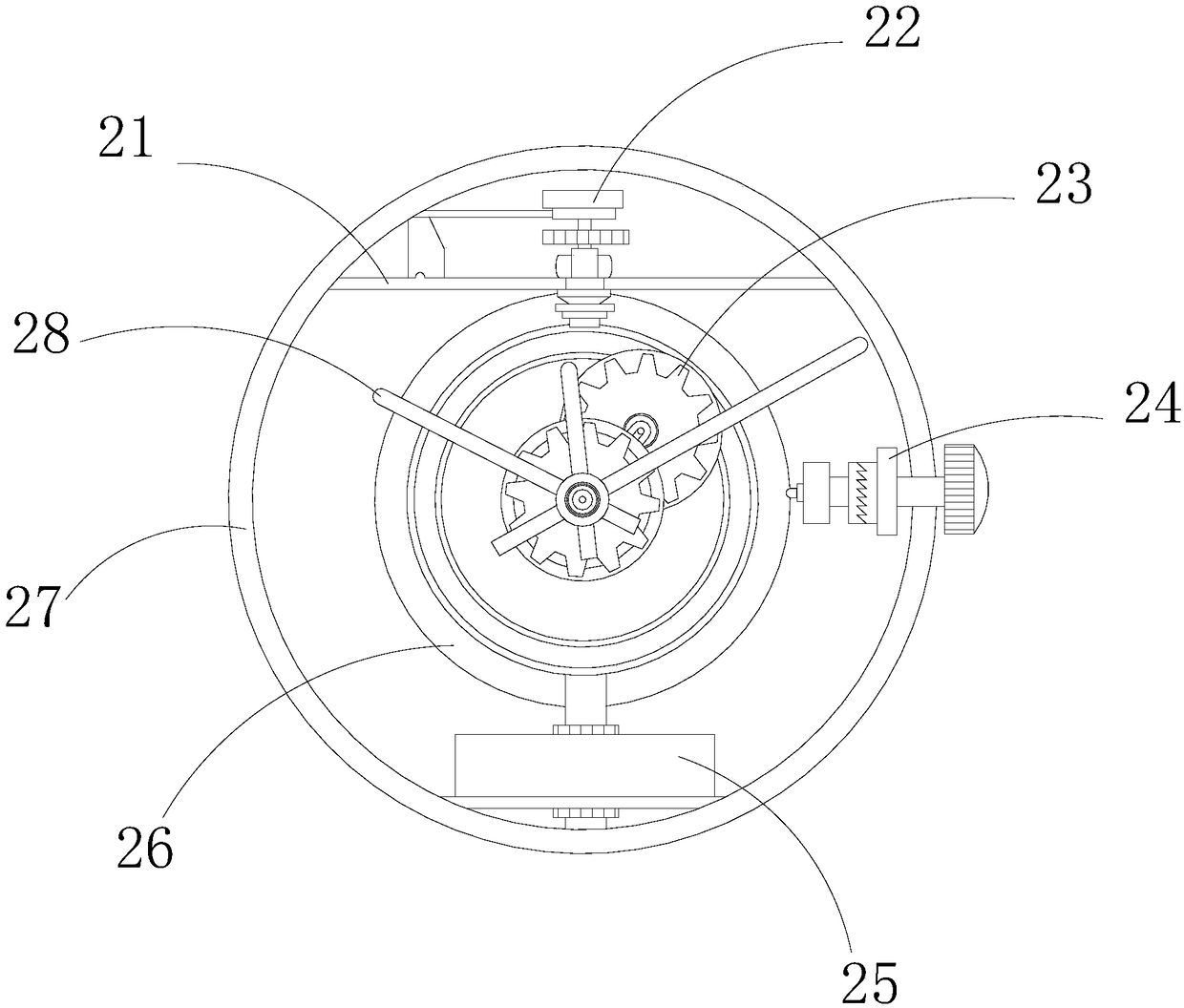

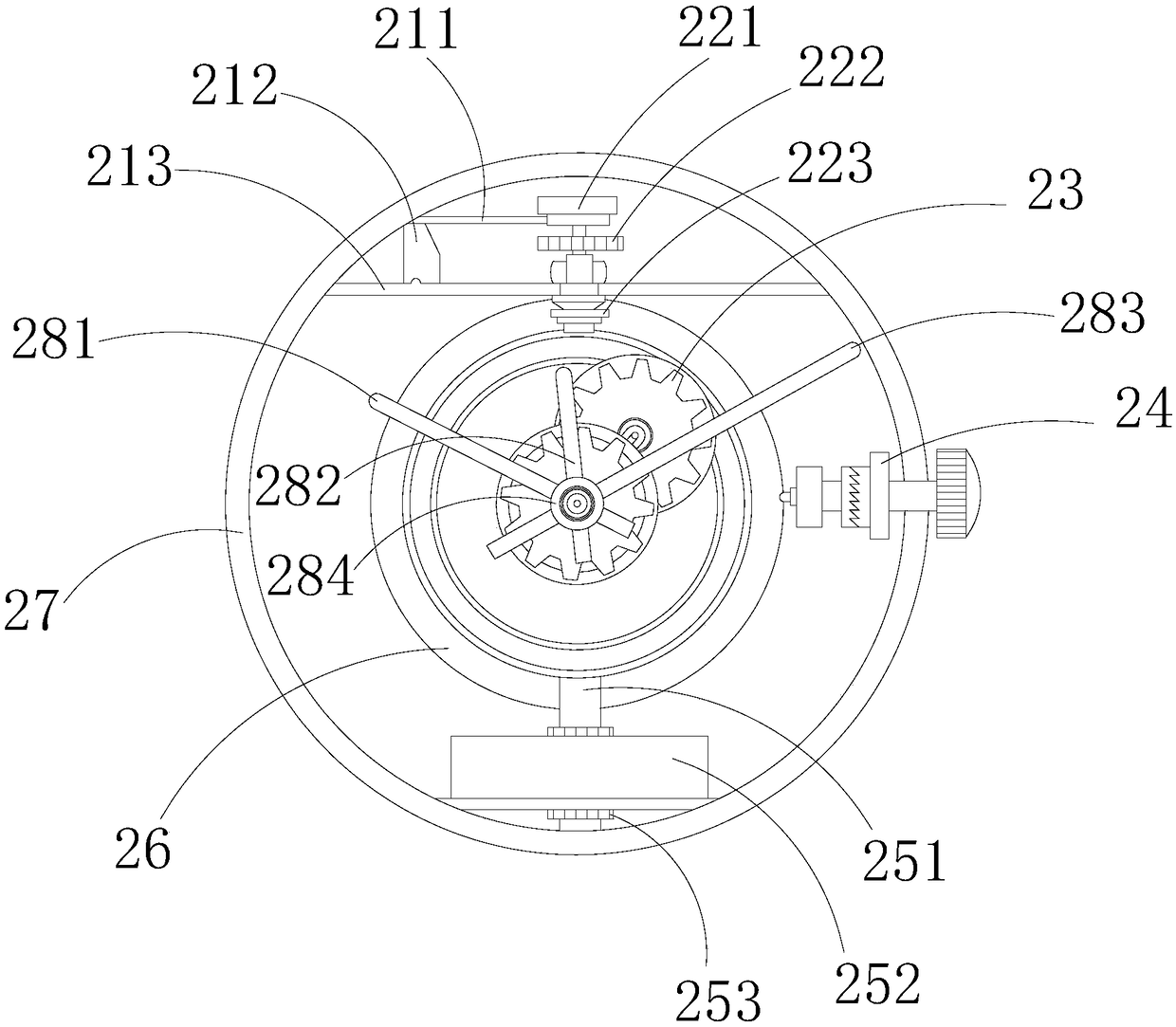

[0023] Such as Figure 1-Figure 5 As shown, the present invention provides a watch winding device, the structure of which includes: a watch needle 1, a winding device 2, a watch case 3, a watch strap 4, and a fixing device 5. The watch needle 1 is horizontally installed on the front end of the watch case 3 and The winding device 2 adopts mechanical connection, the section of the winding device 2 is a circular structure and is horizontally fixed on the rear end of the watch needle 1 and is matched with each other. The watch case 3 is collinear with the axis of the winding device 2. There are two straps 4 that are evenly installed on the left and right ends of the watch case 3 and adopt clearance fit. The fixing device 5 and the watch strap 4 are of an integrated structure. 22. Composed of cross-wheel shaft teeth 23, swing lever 24, balance wheel lower shaft 25, balance wheel 26, dial 27, and pointer system 28, the pressure plate lever spring 21 is vertically installed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com