Screw-type extruder

A technology of extruder and screw type, which is applied in applications, household appliances, flat products, etc., and can solve problems such as difficult forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

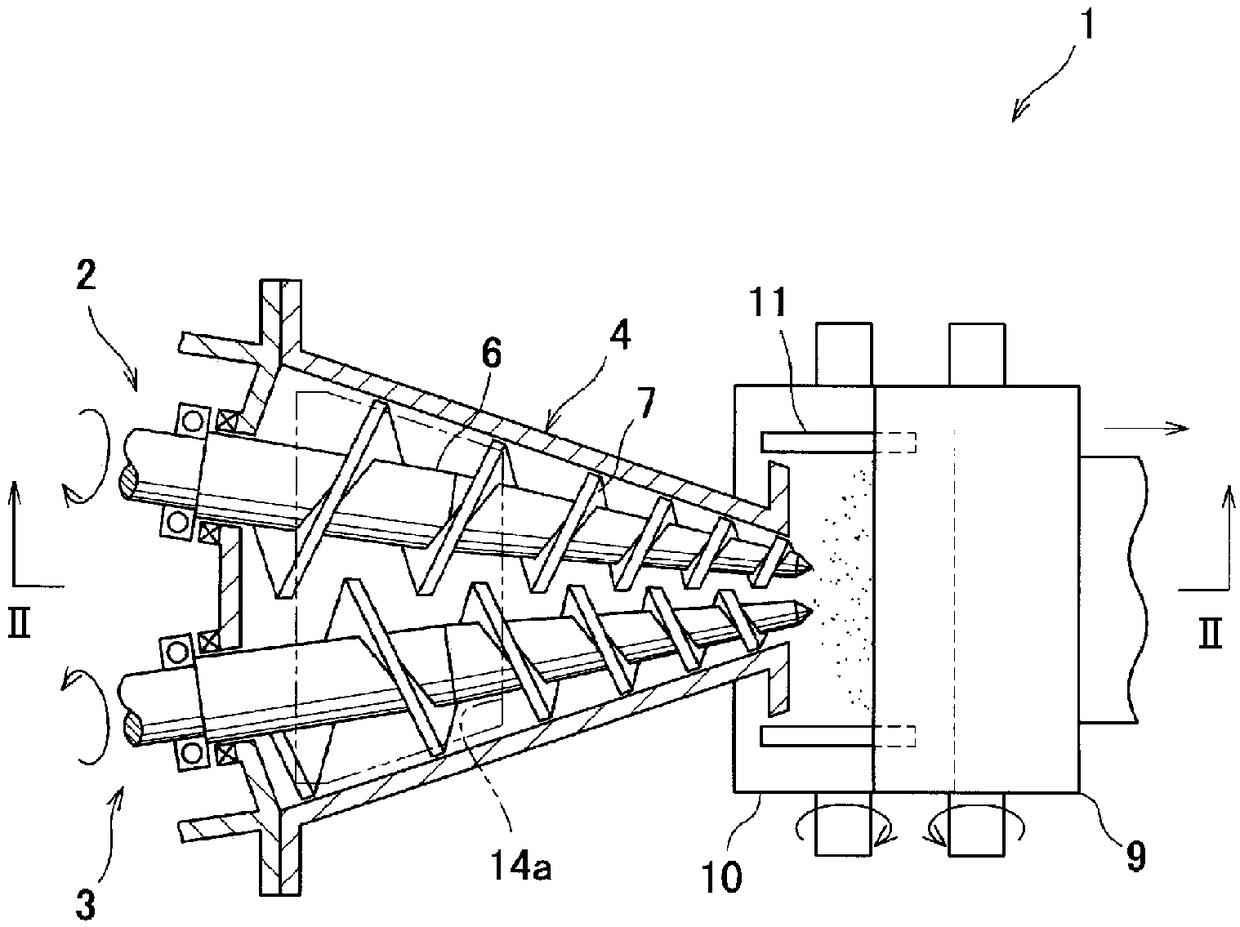

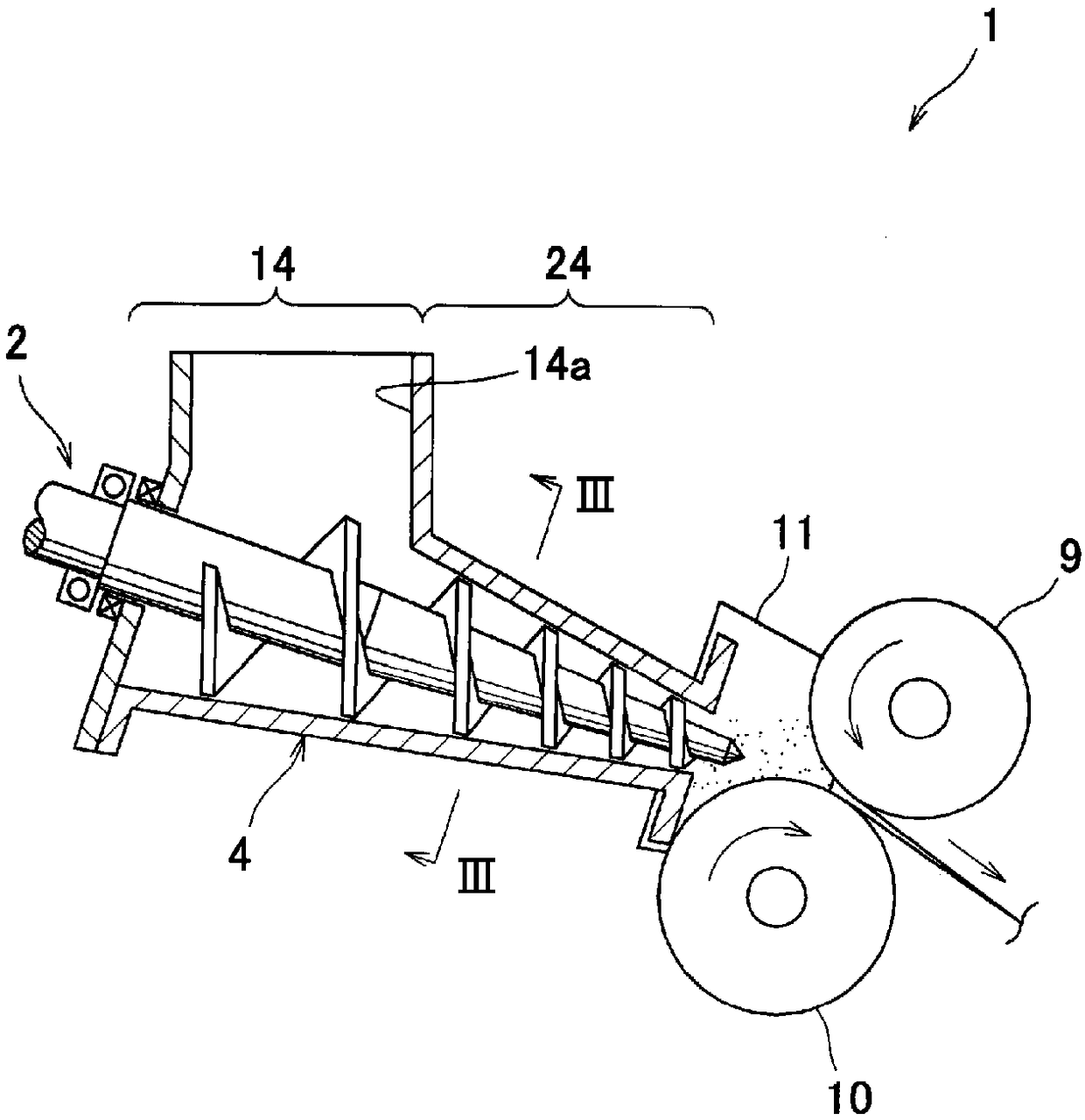

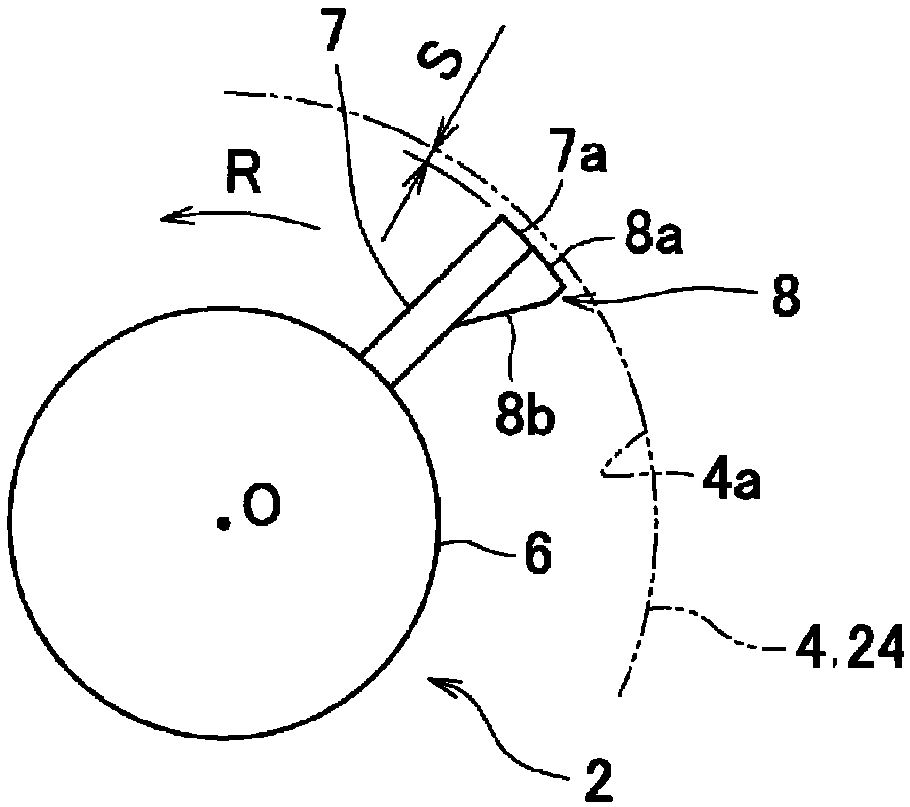

[0032] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. The screw extruder shown in the following embodiments is a screw extruder with a roll die (hereinafter referred to as "extruder with a roll die") that extrudes a kneaded product of a polymer material such as rubber into a sheet. Exit"). It should be noted that the screw extruder of the present invention can also be used to extrude the kneaded polymer material from a die with many circular holes and then cut into cylindrical particles, which is called granulation. machine machinery.

[0033] (Structure of extruder with roll die)

[0034] refer to Figure 1~3 , the extruder 1 with a roll die according to one embodiment of the present invention will be described. The extruder 1 with a roll die has two screws (first screw 2 and second screw 3 ) for extruding a kneaded product, and a chamber 4 for accommodating the screws 2 and 3 . A pair of upper and lower roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com