Efficient manufacturing process for masonry mortar

A manufacturing process and masonry mortar technology, applied in the direction of pretreatment control, clay preparation device, mixing operation control, etc., can solve the problems of weak crushing ability and low mixing uniformity, and achieve strong dispersion effect, high dispersion effect, The effect of high mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

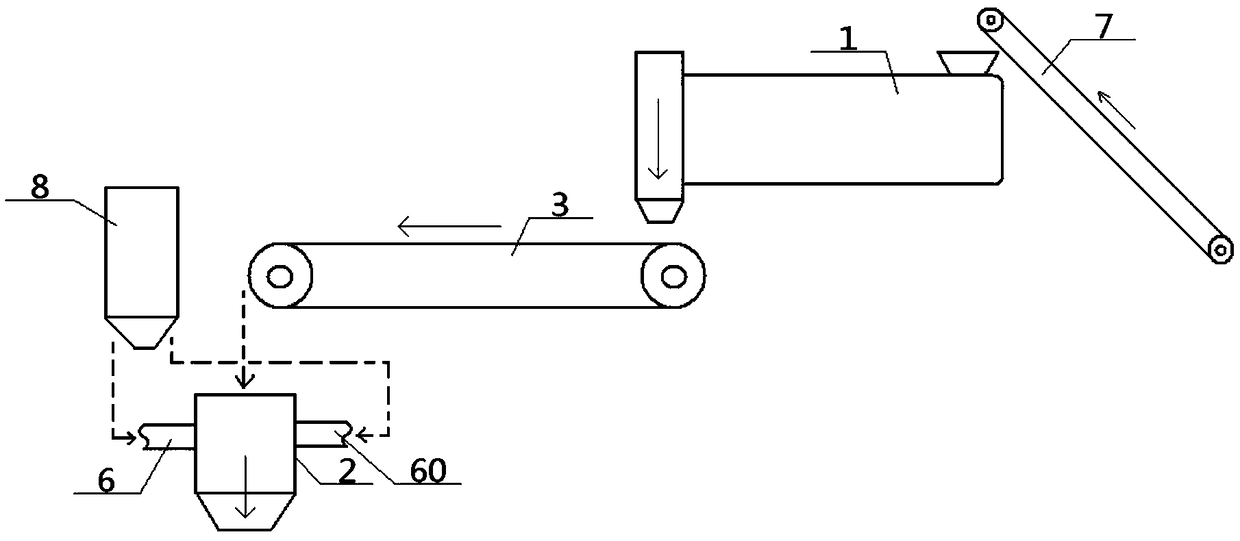

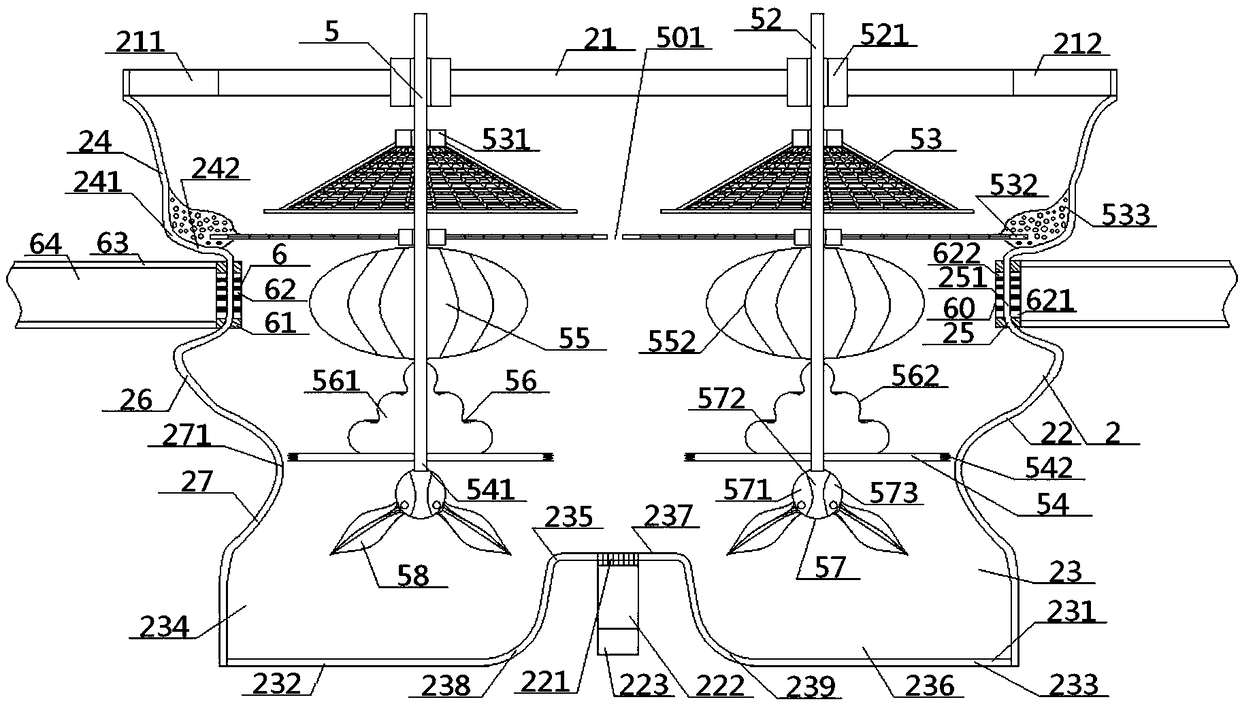

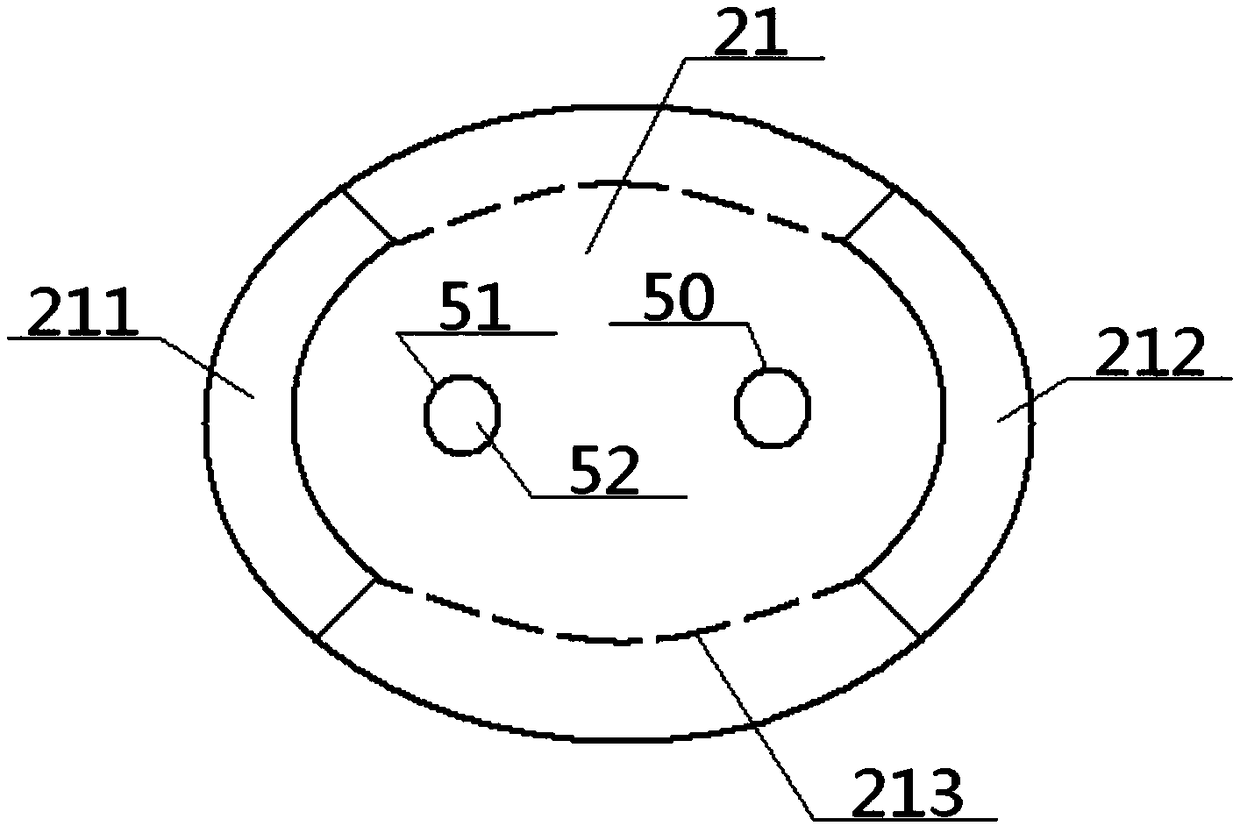

[0058] see Figure 1 to Figure 10 , a high-efficiency manufacturing process for masonry mortar, comprising the following steps: first conveying the sand material to the drying drum 1 by the sand material conveyor belt 7, and then drying the sand material in the drying drum 1 to obtain dry material, and the resulting dry material is conveyed to the dry material conveyor belt 3, and then the dry material conveyor belt 3 sends the dry material into the outer mixing drum 2, and at the same time, the auxiliary material feeder 8 sends the auxiliary material into the outer mixing drum 2 Inside; before the dry material and auxiliary materials enter the outer mixing drum 2, first drive the stirring shaft 52 in the left stirring unit 51 and the right stirring unit 50 to rotate respectively, and the top of the stirring shaft 52 is set higher than the top of the outer stirring drum 2, and the stirring shaft The bottom end of 52 extends down to the inside of the outer mixing drum 2, and th...

Embodiment 2

[0061] Basic content is the same as embodiment 1, the difference is:

[0062]The shaft attachment 55 includes a shaft attachment cylinder 551 and a plurality of shaft attachment blades 552, the inner wall of the shaft attachment cylinder 551 is fixedly connected with the outer wall of the stirring shaft 52 passing through it, and the outer wall of the shaft attachment cylinder 551 is connected with the shaft attachment The inner ends of the blades 552 are connected, the outer ends of the blades 552 with shafts extend outward, and the blades 552 with shafts are evenly arranged on the cylinder 551 with shafts. The shaft-attached blade 552 is a concave arc-shaped structure, and an arc-shaped shaft-attached angle 553 is formed between the inner end of the attached shaft blade 552 and the outer wall of the shaft-attached cylinder 551 .

Embodiment 3

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] The position between the attached shaft 55 and the bottom stirring plate 54 on the stirring shaft 52 is covered with a hollow wave cylinder 56, the top of the wave cylinder 56 is connected with the stirring shaft 52, and the bottom of the wave cylinder 56 is connected with the The top surface of the bottom stirring plate 54 is connected, the inside of the wave cylinder 56 is provided with a wave cavity 561, the outer surface of the wave cylinder 56 is provided with a plurality of wave drums 562, and the top of the wave cylinder 56 is narrower than its bottom end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com