Feeding splitter, flame-retardant nylon manufacturing device and method for manufacturing flame-retardant nylon

A flame-retardant nylon and manufacturing device technology, applied in the field of nylon composite material manufacturing, can solve the problems of troublesome replacement and maintenance of the shunt, large differences in particle size, and the inability of the shunt to move, so as to improve the connection, dispersibility and dispersibility. The effect of improving and expanding application and use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

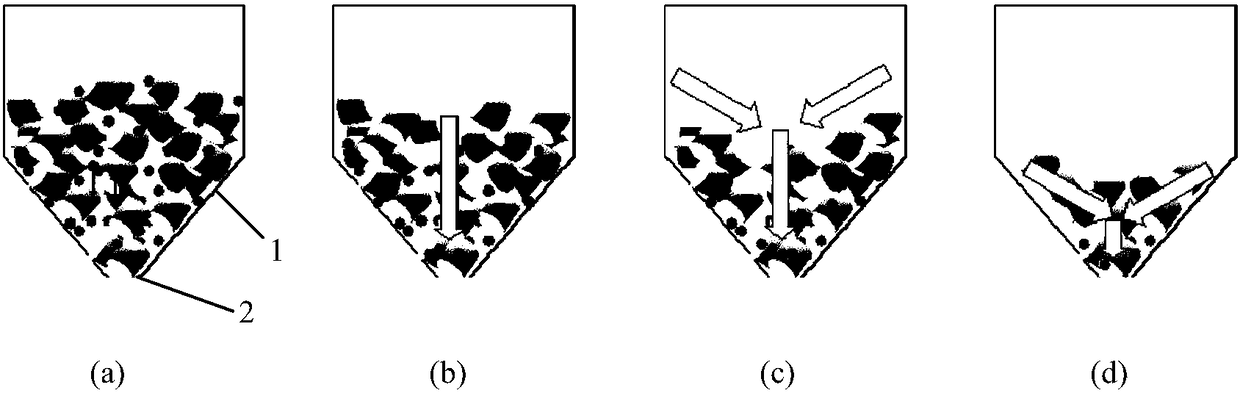

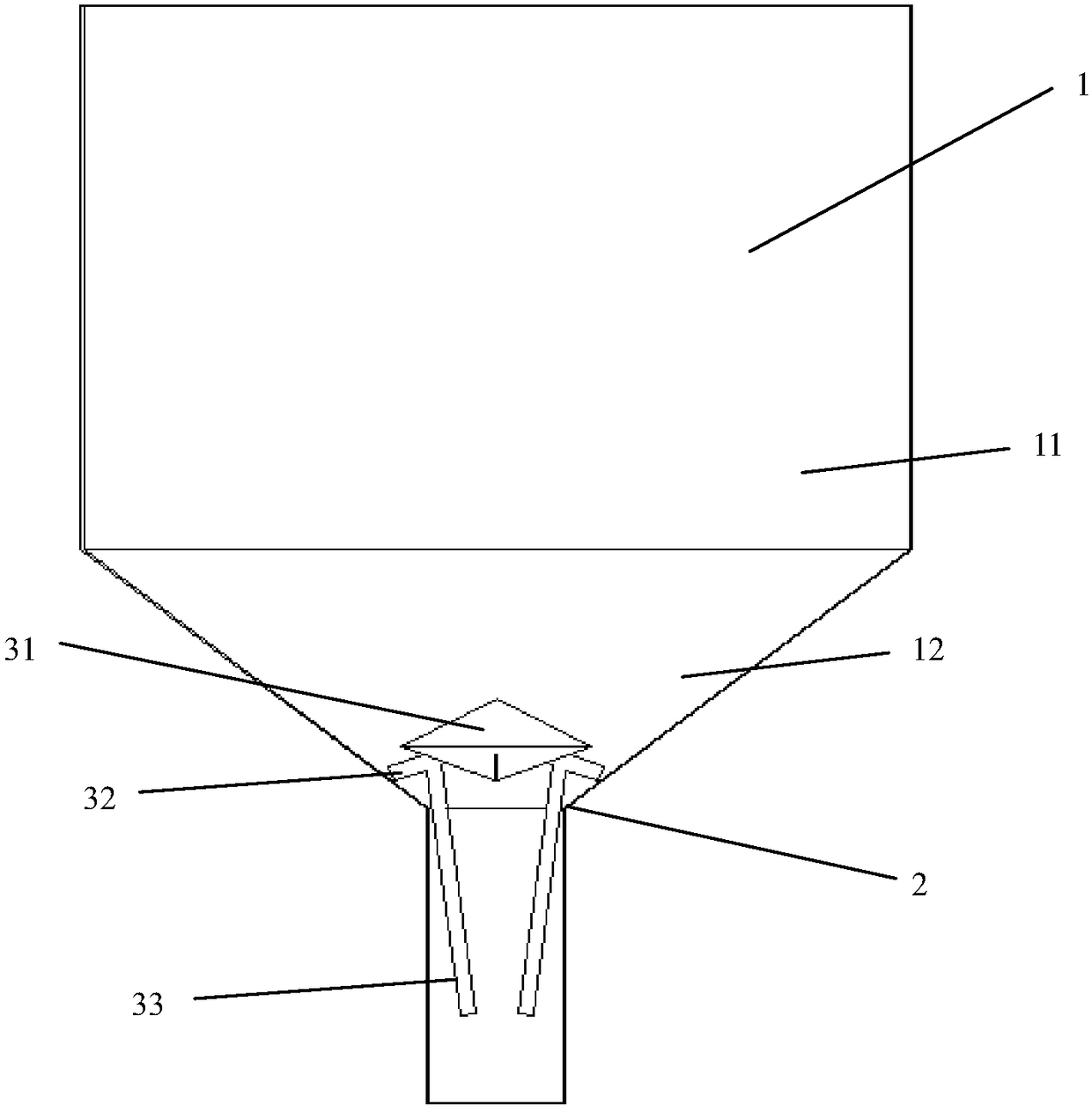

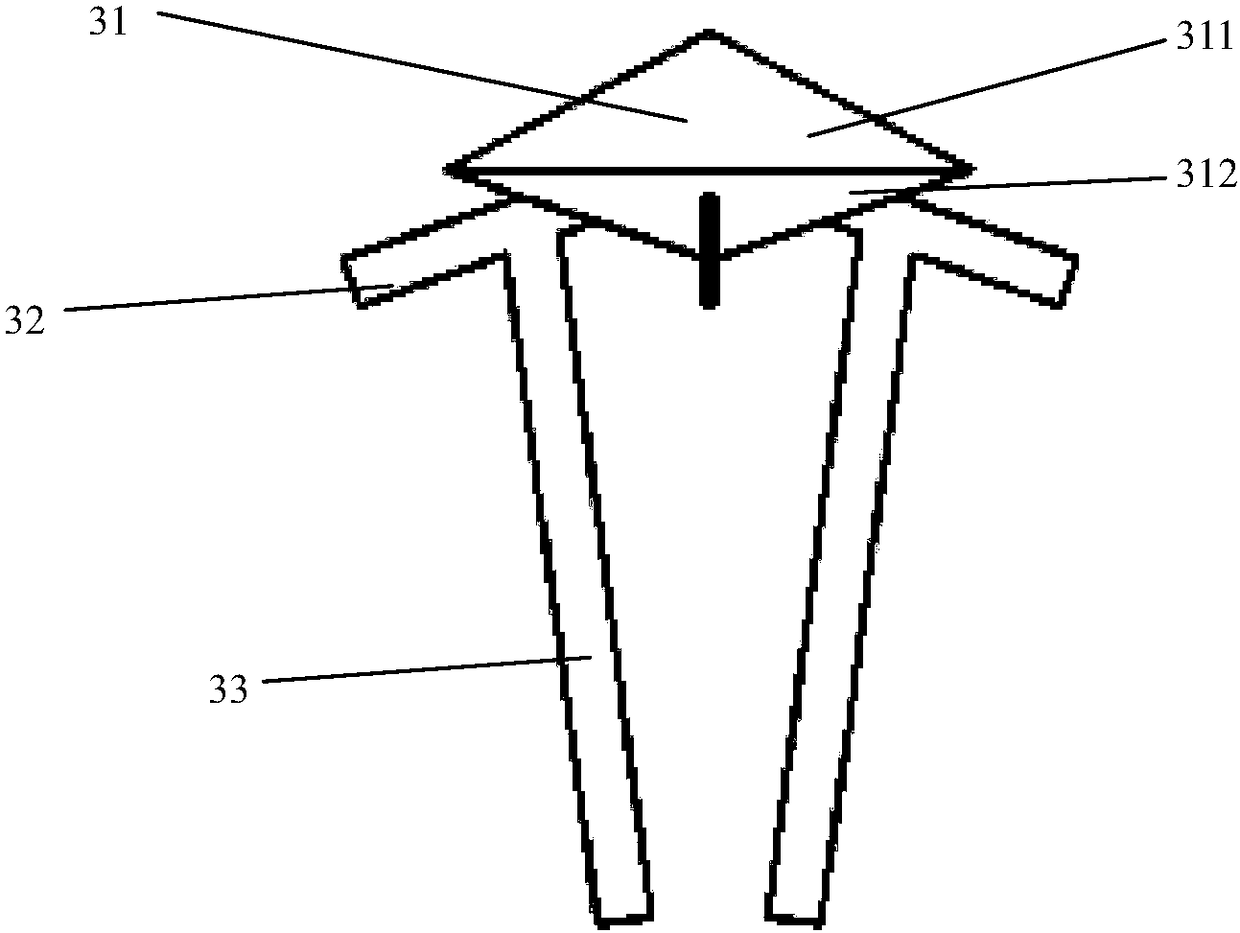

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] The specific embodiment of flame-retardant nylon manufacturing device of the present invention, as Figure 2 to Figure 6 As shown, the flame-retardant nylon manufacturing device of this embodiment includes a feeding bin and a screw extrusion device connected to the feeding bin. The feeding bin includes a barrel 1 and a discharge port 2. The barrel 1 includes a circular barrel arranged in a vertical direction. body 11 and a conical cylinder 12 fixedly connected to the lower end of the circular cylinder, the upper end of the conical cylinder 12 is welded to the lower end of the circular cylinder 11, and the inner diameter of the upper opening of the conical cylinder 12 is the same as the inner diameter of the circular cylinder 11 , the lower end of the conical cylinder 12 is connected with the discharge port 2, the inner diameter of the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com