Process for converting a reactor from base-catalyzed polyol production to dmc-catalyzed polyol production

A DMC catalyst and reactor technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problem of reducing the catalytic activity of DMC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

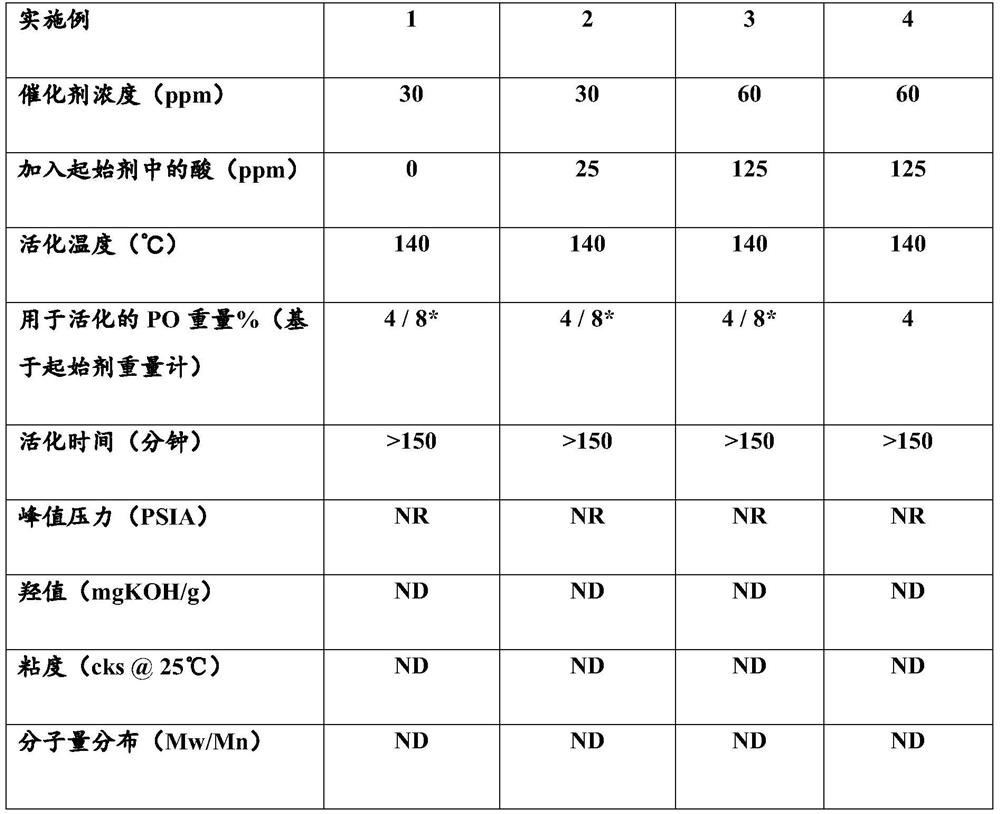

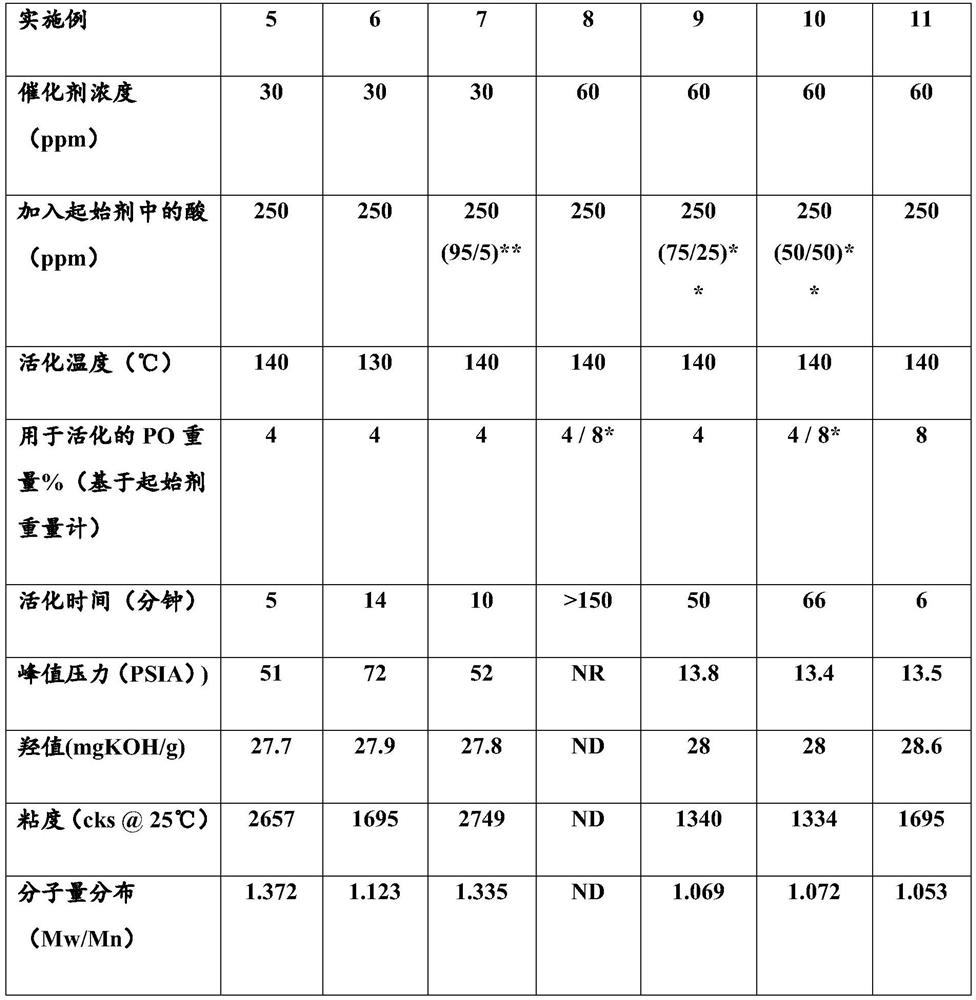

Examples

Embodiment

[0024] Preparation of polyether polyols

[0025] The base-catalyzed polyol preparation reaction and the resulting base-catalyzed product mixture were simulated by combining a polyoxypropylene triol with a hydroxyl number of 56 mg KOH / g and a total polyoxypropylene triol and potassium hydroxide-based A 5 gallon mixture of 0.33% by weight potassium hydroxide ("base catalyzed product simulant") was charged to an 8 gallon continuously stirred tank reactor. The base-catalyzed product simulant was stirred and heated in the reactor at a temperature of 100°C for 60 minutes. The unneutralized base-catalyzed product simulant was then vented from the reactor while purging with nitrogen for 20 minutes at 60°C.

[0026] The starter mixture was charged to the vented reactor in an amount sufficient to provide a build ratio of 8.5 (2414 grams). After the base-catalyzed product simulant is drained from the reactor, the reactor is not washed, rinsed, or otherwise treated to remove residual ...

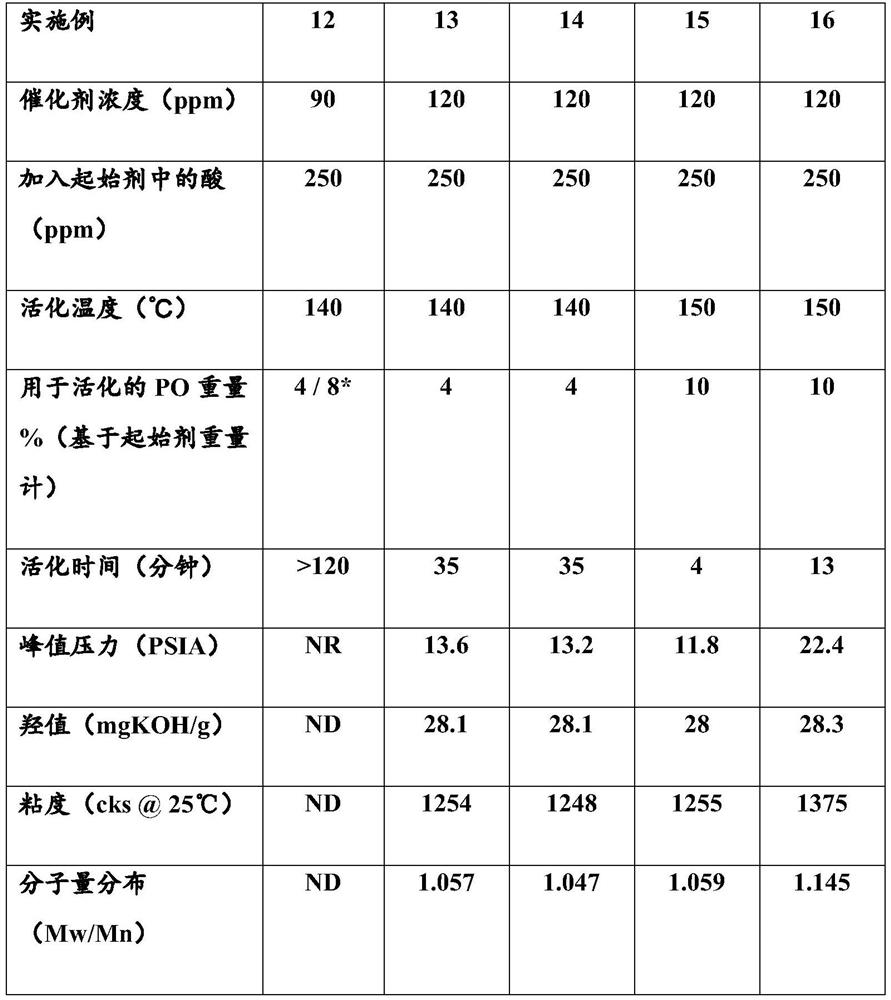

Embodiment 31

[0052] Example 23 was repeated (90 ppm catalyst, 500 ppm phosphoric acid, 140°C reaction temperature, 4% PO added for activation), except that the initiator mixture was added to the reactor instead of washing the reactor, Under conditions where the base-catalyzed product simulant was flushed or otherwise treated to remove its residue after it was withdrawn from the reactor, 0.9% of the base-catalyzed product simulant was added to the starter mixture (based on starting 177 grams based on the total weight of the reagent mixture and the added base-catalyzed product simulant). A starter mixture containing 0.9% base-catalyzed product simulant was added to a clean reactor free of residual base-catalyzed product simulant from previous base-catalyzed polyol product simulations. The activation time of the DMC catalyst was 5 minutes and the reactor was maintained at a pressure typical for DMC catalyzed polymerization with a peak pressure of 13.9 psia. The hydroxyl value of the final pr...

Embodiment 32-34

[0055] Using a "base-catalyzed product simulant" similar to that described above, the initiator mixture was charged to the vented reactor in an amount sufficient to provide a build ratio of 4 (4968 grams). After the base-catalyzed product simulant is drained from the reactor, the reactor is not washed, flushed, or otherwise treated to remove residual base-catalyzed product simulant. The starter mixture comprises a polyether polyol starter (polyoxypropylene triol with a hydroxyl value of 233-243 mg KOH / g), 30-120 ppm of hexacyanocobalt based on the total weight of the final product A zinc acid DMC catalyst, and 0 to 1000 ppm of phosphoric acid based on the total weight of the starter mixture. The starter mixture was heated to 130° C. in the reactor while purging with nitrogen under vacuum for 30 minutes. The reactor is then heated to a reaction temperature of 130-150°C, the reactor is sealed under vacuum, and 4 to 10% of propylene oxide (based on the total weight of the initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com